When it comes to hazardous area inspections, accuracy and safety go hand-in-hand. Intrinsically safe infrared (IR) cameras are specialized thermal imaging tools designed to detect heat signatures without igniting explosive gases or dust. From oil and gas refineries to mining operations and chemical plants, these devices are critical for preventive maintenance, leak detection, and safety compliance.

In this guide, we’ll break down the intrinsically safe infrared camera price, certification standards, common sensor specs, and temperature ranges. You’ll also learn what affects the cost, how to choose the right model for your application, and how to request a demo or quote directly from Intrinsically Safe Store.

Shop intrinsically safe & explosion-proof cameras and essential resources:

What Is an Intrinsically Safe Infrared Camera?

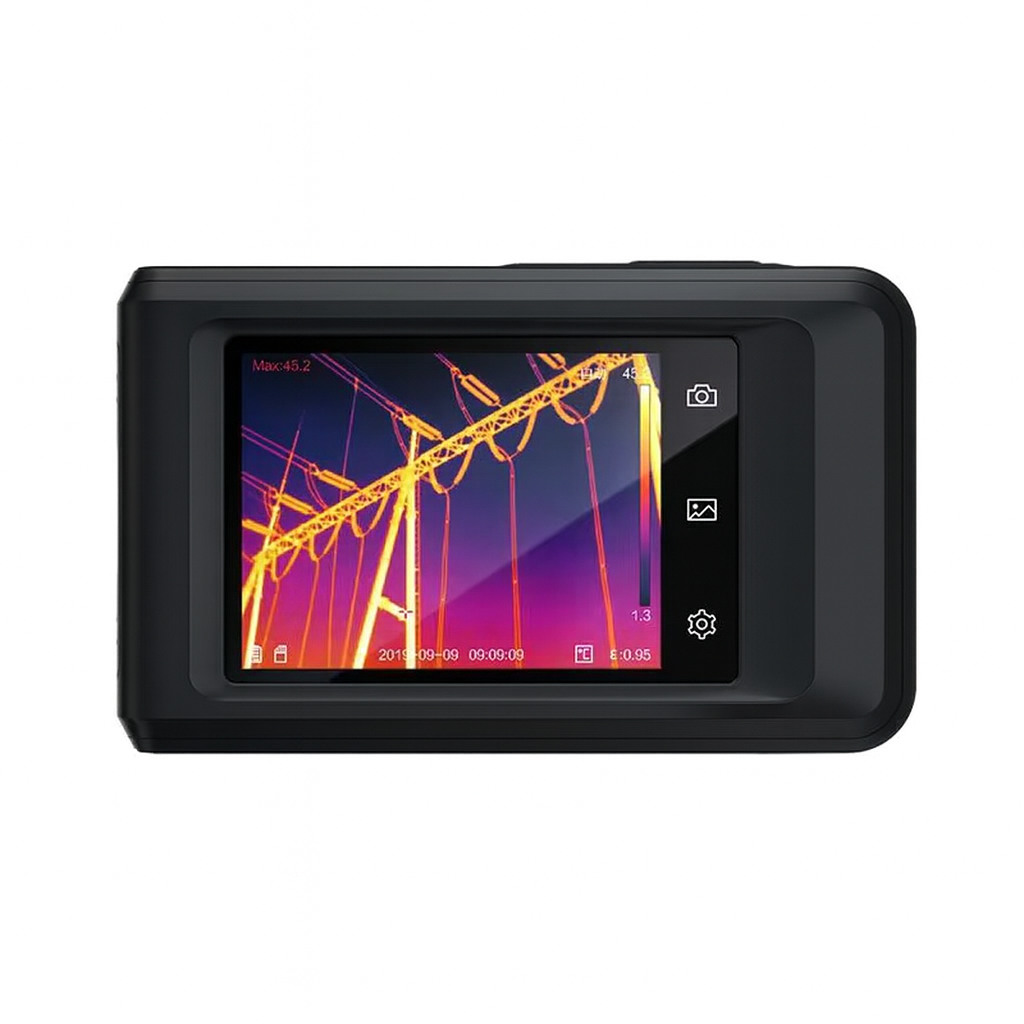

An intrinsically safe infrared camera (also called a thermal imaging camera) is designed to measure surface temperatures and visualize heat patterns in hazardous (classified) areas where explosive gases, vapors, or dust may be present.

Unlike standard IR cameras, intrinsically safe models are engineered to prevent sparks, heat buildup, or electrical discharge that could trigger an explosion. They’re built for Zone 1 / Division 1 environments under certifications like ATEX, IECEx, or UL Class I, Division 1.

Key Components

Infrared Sensor: Converts thermal radiation into an electronic signal.

Lens Assembly: Focuses IR energy on the sensor.

Display Module: Shows live heat maps or thermal gradients.

Housing: Explosion-proof enclosure designed for safe use in hazardous areas.

How Much Does an Intrinsically Safe Infrared Camera Cost?

The intrinsically safe infrared camera price depends on certification, sensor type, and image resolution.

While prices are typically not listed publicly due to quote-based industrial sales, the average cost for certified IR cameras ranges between $2,000 and $9,000 USD.

Typical Pricing Breakdown

| Camera Type | Approx. Price Range (USD) | Certification | Resolution | Typical Use |

|---|---|---|---|---|

| Entry-Level Thermal Imager (IS Certified) | $2,000 – $3,500 | ATEX / IECEx Zone 1 | 80×60 to 160×120 | Basic inspections, temperature screening |

| Mid-Range Industrial IR Camera | $3,500 – $6,500 | ATEX / UL Div. 1 | 320×240 | Maintenance, leak detection |

| Advanced High-Resolution IR System | $6,500 – $9,000+ | ATEX, IECEx, UL | 640×480+ | Precision diagnostics, predictive maintenance |

Note: Prices are approximate and may vary based on certification level, sensor quality, and accessories. Contact Intrinsically Safe Store for an official quote.

Need help choosing the right certified IR camera? Talk to a Safety Expert.

Why Are Intrinsically Safe Cameras More Expensive?

The higher cost of intrinsically safe infrared cameras reflects the specialized engineering and rigorous testing required to meet international safety standards.

Key Cost Drivers

Certification Compliance: Testing for ATEX/IECEx or UL Class/Div standards adds cost due to strict design and safety audits.

Reinforced Housing: Explosion-proof enclosures are heavier and more durable than standard housings.

Precision Sensors: High-resolution microbolometers or cooled detectors improve thermal accuracy but raise manufacturing costs.

Temperature Range: Broader detection ranges (e.g., –20°C to 650°C) add to the sensor’s complexity.

Accessories: Kits with lenses, calibration tools, and protective cases can raise total cost.

What Sensors Do Intrinsically Safe IR Cameras Use?

Most intrinsically safe IR cameras rely on microbolometer sensors, which detect thermal energy without direct contact. These sensors convert heat into visible color gradients on the camera’s display.

Common Sensor Specifications

| Sensor Type | Resolution | Temperature Range | Sensitivity | Typical Use |

|---|---|---|---|---|

| Uncooled Microbolometer | 160×120 or 320×240 | –20°C to +550°C | <0.08°C | General maintenance, electrical panels |

| High-Resolution Microbolometer | 640×480 | –40°C to +650°C | <0.05°C | Gas detection, precision inspections |

| Cooled Detector (rare) | 1024×768 | –50°C to +1,000°C | <0.03°C | Specialized industrial analytics |

Most intrinsically safe cameras use uncooled microbolometers, as they are compact, reliable, and consume less power — critical for intrinsic safety compliance.

How Do Temperature Range and Sensitivity Affect Price?

1. Temperature Range

Wider temperature detection capabilities increase cost because they require more advanced sensors and calibration algorithms.

Entry-level IR cameras typically measure up to 550°C.

Industrial-grade units can handle up to 1,000°C for heavy industrial applications.

2. Thermal Sensitivity

A lower NETD (Noise Equivalent Temperature Difference) means the camera can detect smaller differences in heat — essential for detecting minute leaks or hotspots.

High-sensitivity sensors (<0.05°C) are more expensive but provide significantly more detail.

What Certifications Should You Look For?

Certifications confirm that a device is safe for use in explosive environments.

| Certification | Region | Standard | Environment |

|---|---|---|---|

| ATEX (Directive 2014/34/EU) | Europe | EN 60079 | Zone 1 / Zone 2 (Gas) |

| IECEx | International | IEC 60079 | Global equivalent of ATEX |

| UL / CSA (Class I, Div. 1) | North America | UL 913 / CSA 60079 | Hazardous gas and dust zones |

Best practice: Choose a camera that meets at least one global certification standard relevant to your site’s classification.

What’s Included in a Typical IR Camera Kit?

Intrinsically safe IR cameras often come as kits to support safe deployment and calibration.

Typical Kit Components

Certified IR Camera Unit

Rechargeable Battery Pack (IS rated)

Calibration Certificate

Carrying Case (shock-resistant, sealed)

Software License / Data Cable

Optional Demo Unit or Trial Access

For many industrial clients, Intrinsically Safe Store provides demo or trial units upon request — allowing teams to test performance before committing to a full purchase.

How to Choose the Right Intrinsically Safe IR Camera

When evaluating IR cameras, focus on application-driven requirements instead of only the price tag.

Key Factors to Consider

Area Classification: Confirm your operating zone (Zone 1/2 or Div. 1/2).

Temperature Range: Ensure it matches your process environment.

Resolution Needs: Choose higher resolution for detailed inspections.

Data Output: Look for USB, Wi-Fi, or Bluetooth (if safely enclosed).

User Interface: Touchscreen or button-controlled models depending on PPE use.

Ergonomics: Consider size, weight, and balance for handheld operation.

Get a tailored recommendation:

- Tell us your Zone/Division, temperature range, and resolution needs.

- We’ll match the best certified IR cameras for your use case.

What Is the Ordering Process?

Because intrinsically safe IR cameras are certified industrial instruments, pricing and availability are typically managed through a Request for Quote (RFQ) or demo request system.

How to Request a Quote or Demo

Visit the Intrinsically Safe Store Camera Category.

Select “Request a Quote” or “Request a Demo.”

Provide details such as intended use, certification requirements, and desired temperature range.

A technical specialist will respond with a tailored quote and lead time.

FAQs About Intrinsically Safe Infrared Cameras

1. What makes a camera “intrinsically safe”?

It’s designed to limit electrical and thermal energy so it cannot ignite flammable gases or dust. Certified testing verifies compliance with ATEX, IECEx, or UL standards.

2. Are all thermal cameras intrinsically safe?

No. Most commercial IR cameras are not intrinsically safe. Only those explicitly certified can be used in hazardous zones without additional protective measures.

3. What is the typical lifespan of an intrinsically safe IR camera?

High-quality units last 5–10 years, depending on usage and maintenance. Regular calibration ensures consistent accuracy.

4. Can these cameras detect gas leaks?

Some advanced IR cameras can detect volatile organic compound (VOC) emissions or hydrocarbon gas leaks based on temperature contrast.

5. How often should IR cameras be calibrated?

For industrial and safety applications, recalibration is recommended annually or after any significant impact or exposure to extreme conditions.

Ready to spec the right intrinsically safe IR camera?

Instant answers via chat or call our team for a custom recommendation.

Conclusion

Intrinsically safe infrared cameras combine cutting-edge thermal imaging with explosion-proof design — making them indispensable for maintenance, safety, and environmental monitoring in hazardous zones.

While the intrinsically safe infrared camera price varies based on resolution, certification, and sensor type, most certified devices fall within the $2,000–$9,000 range. The investment ensures accurate diagnostics while keeping personnel safe.