Inspection inside hazardous environments requires tools that deliver high-quality visual data without creating ignition risk. Whether you’re assessing pipelines, vessels, confined spaces, or process equipment, choosing the right intrinsically safe inspection camera is essential for safety, compliance, and inspection accuracy.

In this guide, you’ll learn exactly how pricing varies across models, which zoom and sensor options matter most, and how to compare borescopes and inspection cameras built specifically for hazardous areas.

Need help choosing an intrinsically safe inspection camera?

Talk to our hazardous-area specialists and find the right IS camera or borescope for your inspections.

Browse Intrinsically Safe Cameras Chat with a Hazardous-Area ExpertPrefer to call? Speak with our team at 832 699 6726.

What Is an Intrinsically Safe Inspection Camera?

An intrinsically safe inspection camera is a visual inspection tool engineered so that its electrical and thermal energy cannot ignite flammable gases, vapors, or dusts—even in fault conditions. These cameras are certified under standards like ATEX, IECEx, and Class I, II, III Divisions, ensuring safe operation inside hazardous locations.

Typical applications include:

Oil & gas facilities

Petrochemical plants

Mining operations

Grain, food, and dust processing zones

Utilities, wastewater, power generation

Aviation fuel systems

Hazardous confined spaces

Because inspection often involves entering hard-to-reach or potentially explosive conditions, IS-certified borescopes and inspection cameras must be rugged, reliable, and engineered for safe close-range imaging.

How Much Does an Intrinsically Safe Inspection Camera Cost?

Pricing varies widely depending on certification level, optical features, sensor quality, and probe design. Below is a reliable pricing tier framework:

Entry-Level (Typically Zone 2 or Class I Div 2)

$2,000–$5,000

Basic zoom and fixed-lens options

Standard HD sensors

Limited borescope articulation

Ideal for light industrial inspections in lower-risk areas

Mid-Range (Zone 1, Class I Div 1 Capable)

$5,000–$10,000

Optical zoom up to 4×

Rugged housings, advanced lighting, long exposure

Better low-light performance, improved signal processing

Suitable for oil & gas, chemical plants, refineries

Premium Tier (Zone 0 or High-Spec Borescopes)

$10,000–$20,000+

Full IS certification (Ex ia / Zone 0)

Articulating probes with 180°–360° movement

High-resolution sensors (10–12 MP+)

Thermal or dual-sensor options

Ideal for mission-critical inspections in the highest-risk zones

What Drives the Cost?

| Factor | Impact on Price | Reason |

|---|---|---|

| Certification Level | High | Requires extensive testing, documentation |

| Optical Zoom | Medium–High | Precision lenses + rugged engineering |

| Sensor Size & Type | Medium | Larger sensors = better image capture |

| Borescope articulation | High | Highly engineered mechanical assemblies |

| Rugged Housing | Medium–High | IS housings require special materials |

| Data Capture Features | Medium | Storage, metadata, wireless options |

If your inspections occur in a high-risk zone (Zone 0 or Class I Div 1), expect to be in the premium tier.

Comparing pricing tiers for IS inspection cameras?

Explore certified cameras and real-world use cases before you lock in your budget.

View Intrinsically Safe Digital Cameras See Top IS Cameras for Oil & GasNeed a tailored quote for your plant or facility? Start a chat or call 832 699 6726.

What Zoom Features Do Intrinsically Safe Inspection Cameras Offer?

What Type of Zoom Do You Need?

Optical zoom is one of the most important considerations for hazardous-area imaging.

What’s the Difference Between Optical and Digital Zoom?

Optical zoom changes the physical lens distance to magnify a subject without losing clarity.

Digital zoom crops the image and enlarges it electronically, reducing detail.

In hazardous-area inspections, optical zoom is strongly preferred because detail is crucial when evaluating corrosion, weld cracks, gasket wear, or insulation damage.

Typical Zoom Levels Found in IS Cameras

1× (Fixed) – Common in compact borescopes

3× to 4× Optical Zoom – Popular for Zone 1 cameras

Macro/Close-Focus Mode – Essential for welds, threading, pitting, electrical components

Why Zoom Matters for Hazard-Area Inspection

Remote inspection ability

Zoom allows technicians to stay outside a potential hazard while still obtaining detailed images.Access to restricted spaces

Many areas cannot be physically entered, so zoom + borescope articulation becomes essential.Improved defect assessment

Being able to zoom into corrosion, pitting, cracks, or deposits is critical for accurate reporting.

What Sensor Options Should You Look For?

What Makes a Good Sensor for Hazardous-Area Cameras?

Inspection cameras must perform well in poor lighting and confined spaces. Low image quality can lead to misinterpretation, re-inspection, or downtime.

Key Sensor Features

| Feature | Why It Matters |

|---|---|

| Resolution (MP) | Higher MP helps when zooming or cropping |

| Sensor Size | Larger sensors improve low-light performance |

| Dynamic Range | Ensures visibility of dark and bright areas simultaneously |

| ISO Sensitivity | Important in poorly lit vessels or pipelines |

| Video vs. Stills | Some inspections require 4K video playback |

| Color Accuracy | Useful for evaluating corrosion, contamination, residue |

Recommended Specs for Hazardous-Area Work

10–12 MP sensor

1/2.3″ or larger

4K or Full HD video

High ISO for dark spaces

Fast autofocus + macro mode

These specs ensure the camera delivers clear detail even when the lighting or angle is far from ideal.

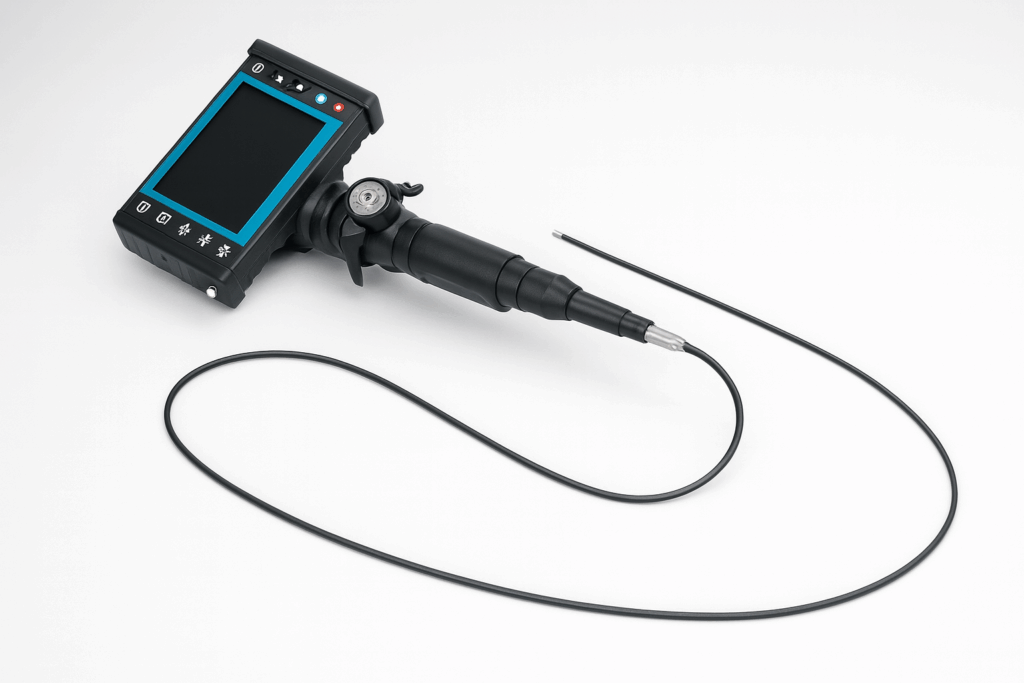

Borescope Options for Intrinsically Safe Inspections

What Makes an IS Borescope Different?

A hazardous-area borescope must maintain intrinsic safety throughout its entire design—including the insertion probe, lights, joints, and articulation controls.

Typical Borescope Features to Compare:

| Feature | Description | Importance |

|---|---|---|

| Probe Diameter | 3–8 mm typical | Smaller = access to tighter spaces |

| Probe Length | 1–5 meters | Longer probes = deep inspections |

| Articulation | 180°/360° steerable tips | Critical for navigating bends |

| Lighting | LED, adjustable, IS-rated | Needed in dark tanks/pipes |

| Durability | Tungsten braid, crush resistant | Prevents probe damage |

| Certification | ATEX / IECEx / CSA | Mandatory for hazardous zones |

Flexible vs. Rigid Borescopes

| Type | Benefits | Limitations |

|---|---|---|

| Flexible Articulating | Versatile, navigates bends easily | More expensive |

| Rigid Borescopes | High optical clarity | Limited flexibility |

| Semi-Rigid | Balance of clarity/flexibility | Moderate articulation |

Flexible articulating borescopes remain the most popular in hazardous industries due to their ability to reach difficult areas.

Comparison Table: Intrinsically Safe Camera Categories

This table helps technicians evaluate which type of equipment fits their inspection needs:

| Category | Certification Level | Optical Zoom | Sensor Quality | Best Use Cases |

|---|---|---|---|---|

| Compact IS Inspection Camera | Zone 2 / Div 2 | 1×–2× | HD | General plant walkdowns, quick checks |

| Rugged IS Camera with Zoom | Zone 1 / Div 1 | 3×–4× | HD/4K | Corrosion inspections, visual maintenance |

| IS Borescope | Zone 1 / Zone 0 | Fixed lens, macro | High clarity | Internal pipe/vessel inspection |

| IS Articulating Borescope | Zone 0 | Macro / steerable | HD | Deep access + high detail inspections |

Which Industries Benefit Most from IS Inspection Cameras?

Inspection tools affect uptime, maintenance cost, and regulatory compliance. Here are industry metrics (summaries aggregated from multiple market analyses):

Oil & Gas: Over 60% of unplanned downtime incidents are related to inaccessible or poorly inspected areas.

Chemical Processing: Annual inspection requirements have grown 15–20% over the last decade due to safety regulations.

Mining: Visual inspections account for 50%+ of all maintenance safety violations.

Food & Grain Processing: Dust hazard areas (Zone 21/22) require more frequent inspections due to heightened ignition risk.

High-quality intrinsically safe inspection cameras significantly reduce reinspection time and improve documentation quality.

Ready to upgrade your intrinsically safe inspection tools?

Get intrinsically safe cameras, borescopes, and connected devices that keep your team compliant and inspection-ready.

Want to go deeper into certifications and device selection?

Class I Div 1 vs Class I Div 2 · Understanding Intrinsically Safe Devices

For quotes or product matching, chat with us or call 832 699 6726.

FAQs About Intrinsically Safe Inspection Cameras

What certification should my intrinsically safe inspection camera have?

Your camera must match the exact classification of your work area. For example:

Zone 0 / Class I Div 1: Highest hazard → requires Ex ia rated equipment

Zone 1: Medium hazard → most IS borescopes fall here

Zone 2: Lower hazard → less expensive cameras may suffice

Always verify the equipment label before use.

Do I need a borescope or a standard IS camera?

Use a standard IS camera for external equipment checks.

Use an IS borescope when inspecting:

Tanks

Heat exchangers

Long pipe runs

Pumps and valves

Internal corrosion points

If you need articulation or tight-space access, a borescope is mandatory.

Is optical zoom necessary for hazardous-area work?

If you need to document damage, corrosion, insulation breakdown, or cracks, then yes—optical zoom helps capture details without physically approaching the hazard.

What is the typical lifespan of an intrinsically safe inspection camera?

With proper care, calibration, and storage, most professional-grade IS inspection cameras last 5–10 years, even in harsh industrial environments.

Can I use a non-certified camera with a protective case in hazardous areas?

No. Using a standard camera inside a hazardous area violates safety standards. The certification applies to the device as a whole—not just its exterior.