Maintaining safe, stable temperature control inside hazardous industrial environments requires more than standard HVAC equipment. Facilities handling flammable gases, vapors, dusts, or combustible fibers rely on a specialized explosion proof HVAC control panel to ensure the system can operate without becoming an ignition source. These panels are engineered to prevent sparks, contain internal explosions, and maintain operational reliability across the most demanding ATEX, IECEx, and Class I/II Division 1 & 2 environments.

This article breaks down the full picture: how explosion-proof panels are designed, which certifications matter, enclosure protection levels, how to assess pricing, integration techniques, industry benchmarks—and how to choose the right solution for oil & gas, chemical plants, manufacturing facilities, waste treatment plants, and other hazardous locations.

What Is an Explosion-Proof HVAC Control Panel?

An explosion-proof HVAC control panel is a specialized electrical enclosure that houses the control systems for heating, ventilation, and air conditioning in hazardous areas. Unlike conventional panels, these units are built to contain ignition-related failures internally, preventing a spark from igniting flammable gases or dusts in the surrounding environment. They are essential in Class I/II/III hazardous locations, ATEX Zones 1 & 2, and any facility where temperature control must occur safely.

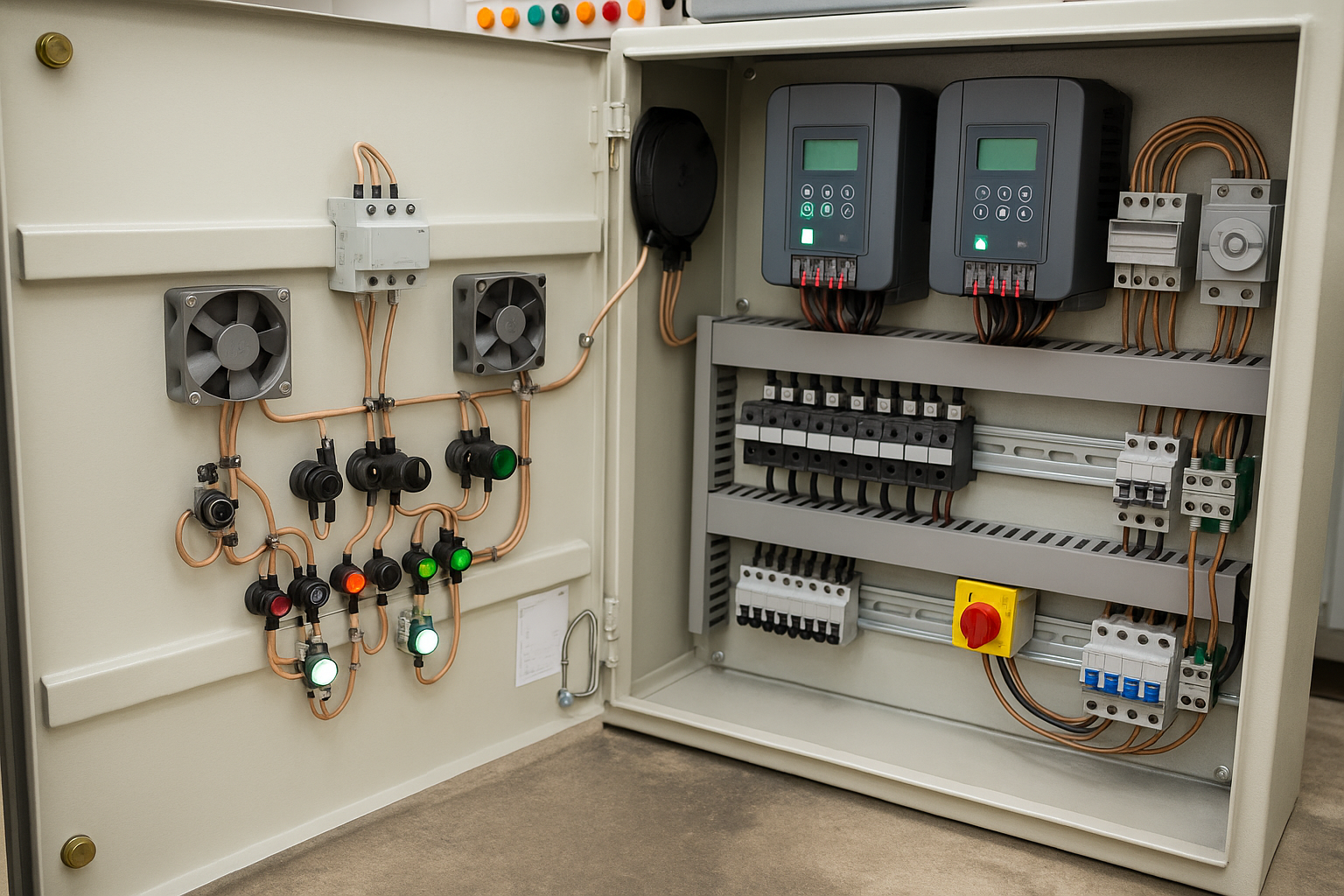

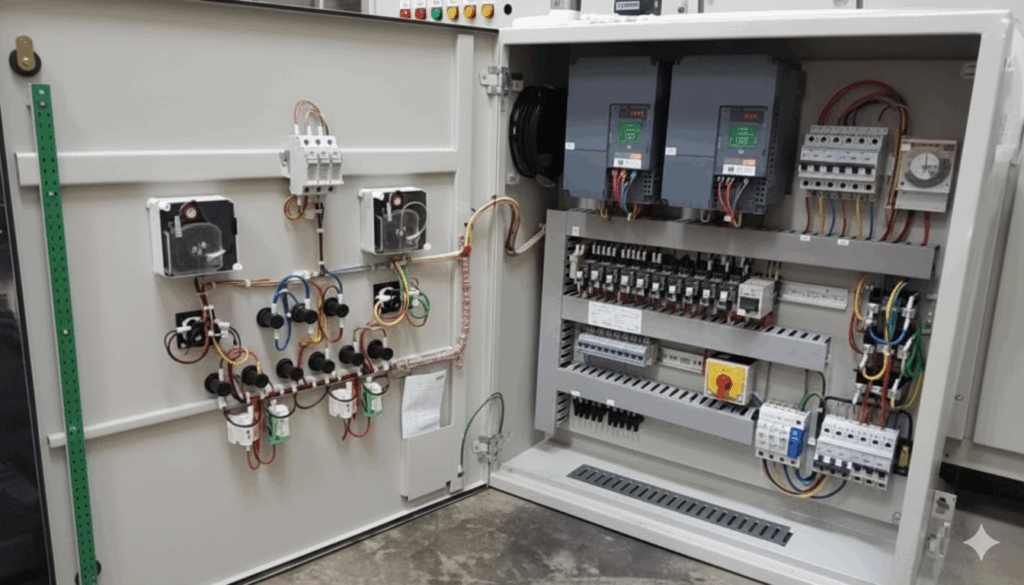

These panels typically include motor starters, VFDs, temperature controllers, PLCs, relays, monitoring systems, and emergency shutdown logic, all engineered for safe operation in explosive atmospheres.

Need an explosion-proof HVAC control panel for your facility?

Browse certified control panels and enclosures engineered for ATEX, IECEx, and Class I/II/III hazardous locations.

Browse Explosion-Proof Control Panels Explore Explosion-Proof Enclosures

Why Are Explosion-Proof HVAC Control Panels Required in Hazardous Locations?

Explosion-proof HVAC control panels are required because traditional HVAC systems contain electrical components capable of producing sparks, heat, and arcs. In hazardous environments—where gases, vapors, or dusts may be present—any spark can trigger catastrophic explosions. To comply with OSHA, NEC, ATEX, and IECEx standards, equipment must be certified and built to meet specific safety objectives.

These panels ensure safe temperature regulation while maintaining operational continuity, regulatory compliance, and asset protection.

What Certifications Does an Explosion-Proof HVAC Control Panel Need?

Explosion-proof HVAC control panels must meet globally recognized hazardous location certifications to ensure they are safe for operation. These certifications confirm that the enclosure, wiring, components, and temperature ratings are suitable for explosive atmospheres. The most common include ATEX, IECEx, UL, CSA, and NEC classifications.

Below is an overview of the essential certification categories.

ATEX Ratings

ATEX certification applies to European Union markets and consists of two directives governing both manufacturers and end users. HVAC panels used in ATEX environments must be labeled with markings such as:

Zone 1 or Zone 2 (gas environments)

Zone 21 or Zone 22 (dust environments)

Equipment Group II (non-mining applications)

Category 2 or 3 depending on protection level

IECEx Certification

IECEx is an international standard confirming compliance for explosive environments. It ensures uniform safety across global industrial facilities. IECEx-certified HVAC panels are often used in multinational projects and are compatible with Middle Eastern, Australian, and some Asian regulations.

NEC/CEC (North America)

In the United States and Canada, classifications follow:

Class I – Gases and vapors

Class II – Dusts

Class III – Fibers

Division 1 – Hazard likely during normal operation

Division 2 – Hazard not likely during normal operation

Explosion-proof HVAC control panels for Class I Div 1 applications typically use flameproof enclosures, while Div 2 may use non-incendive components depending on the installation.

Certification Comparison Table

| Certification | Region | Hazard Type | Typical HVAC Panel Use | Notes |

|---|---|---|---|---|

| ATEX | EU | Gas/Dust | Zones 1, 2, 21, 22 | Mandatory for European projects |

| IECEx | Global | Gas/Dust | Oil & Gas, chemical, mining | Flexible international compliance |

| UL 1203 | North America | Gas/Dust | Class I & II Div 1 | Rigid enclosure testing requirements |

| UL 60079 | Global | Gas/Dust | Zones 1 & 2 | Harmonized with IECEx |

| CSA | Canada | Gas/Dust | Div 1 & 2 | Comparable to UL standards |

Need a deeper dive into hazardous location standards?

Learn how ATEX, IECEx, NEC/CEC and NEMA ratings impact HVAC control panel selection and compliance.

ATEX vs IECEx Explained Class I Div 1 vs Class I Div 2 NEMA Ratings for Explosion-Proof EquipmentWhat Are the Key Design Requirements for an Explosion-Proof HVAC Control Panel?

Explosion-proof HVAC control panels are engineered differently from standard HVAC panels to ensure both functional performance and safety. They integrate multiple layers of protection to prevent ignition sources from ever reaching the hazardous environment.

Here are the core design requirements facility managers and engineers must evaluate.

Flameproof or Explosion-Proof Enclosures

These enclosures must withstand internal ignition and prevent flames from escaping. Typical materials include:

Marine-grade aluminum

316 stainless steel

Cast iron

Many hazardous locations also require corrosion-resistant coatings or NEMA 4X ratings for outdoor conditions.

Intrinsically Safe Circuits (Where Applicable)

Sensors and low-energy circuits may require intrinsically safe barriers to ensure the energy level is always below the ignition threshold. These are common for:

Thermostats

Humidity sensors

Pressure sensors

Purge/Pressurization Systems

Some panels incorporate a purge system compliant with NFPA 496. This allows use of standard components inside a pressurized enclosure that prevents hazardous gases from entering.

Temperature Control Logic and Redundancy

An explosion-proof HVAC control panel must deliver accurate temperature regulation while ensuring safety in failure scenarios. Redundant features may include:

Dual temperature sensors

Backup power or UPS integration

Hot-swappable control modules

Emergency shutdown circuits

Design Component Comparison Table

| Component | Standard HVAC Panel | Explosion-Proof HVAC Panel | Why It Matters |

|---|---|---|---|

| Enclosure | Sheet metal | Flameproof / NEMA / IP66 | Prevents spark escape |

| Wiring | Standard | Armored / sealed glands | Stops gas ingress |

| Sensors | Standard | Intrinsically safe | Eliminates ignition risk |

| Electronics | Unprotected | Purged or explosion-proof | Ensures compliance |

| HVAC Controls | Basic | Redundant, fail-safe logic | Maintains safe operation |

What Enclosure Ratings Are Required for Explosion-Proof HVAC Panels?

Explosion-proof HVAC control panels require enclosures rated to protect against environmental hazards, prevent ingress of flammable materials, and ensure long-term durability. The most common enclosure standards include NEMA, IP, and ATEX Ex d or Ex p.

These ratings ensure safety across humidity, corrosive chemicals, dust, and explosive atmospheres.

NEMA Enclosure Ratings

Explosion-proof HVAC panels typically use:

NEMA 4X – Outdoor, corrosion-resistant

NEMA 7 – Class I Division 1 locations

NEMA 9 – Class II environments with combustible dust

IP Ratings

Common IP ratings include:

IP66 – Dust-tight, protected against strong water jets

IP67/IP68 – Protection against immersion

IP69K – High-temperature washdown

Facilities such as food processing plants often require high-pressure washdown ratings.

ATEX Enclosure Codes

Explosion-proof enclosures must include labels like:

Ex d – Flameproof

Ex p – Pressurized

Ex t – Dust ignition protection

How Do Explosion-Proof HVAC Control Panels Integrate with Industrial Systems?

Explosion-proof HVAC control panels can integrate with distributed control systems (DCS), PLC networks, building automation systems (BAS), and real-time environmental monitoring platforms.

Common Integration Requirements

Modbus RTU/TCP

BACnet MS/TP

EtherNet/IP

PROFINET

Safety relays and SIL-rated logic

Industrial facilities often require remote access and advanced diagnostics to reduce downtime.

Integration Example — Oil & Gas

In offshore drilling sites, HVAC control panels must integrate with:

Pressurization systems for control cabins

Alarm and shutdown networks

Fire & gas detection systems

Explosion-proof chillers

How Much Does an Explosion-Proof HVAC Control Panel Cost?

Pricing depends on certification level, enclosure type, integrations, and custom engineering requirements. Typical cost ranges (based on industry averages):

| Application | Typical Cost Range |

|---|---|

| Class I Div 2 HVAC Panel | $6,000–$15,000 |

| Class I Div 1 Flameproof Panel | $18,000–$40,000 |

| ATEX/IECEx Zone 1 System | $12,000–$35,000 |

| Custom multi-zone panel | $25,000–$75,000+ |

What Drives Pricing?

Hazard classification

Custom PLC programming

Purge/pressurization system

Material of enclosure

Number of HVAC units controlled

Sensor complexity

UL/ATEX testing and documentation

What Components Are Needed to Build an Explosion-Proof HVAC Control Panel?

Explosion-proof HVAC control panels are typically custom engineered, but the core building blocks come from certified hazardous-area components. Intrinsically Safe Store provides many of the essential elements required for assembling compliant HVAC control systems, including enclosures, electrical hardware, and climate-control accessories.

Below are the primary component categories used to build or upgrade an explosion-proof HVAC control panel:

Explosion-Proof Enclosures

These protect internal electronics and prevent ignition sources from escaping the panel.Explosion-Proof Electrical Panels & Panelboards

Used to manage circuits, breakers, and power distribution safely.Hazardous-Area HVAC & Cooling Products

Includes certified air conditioners, coolers, and related climate-control components that integrate with HVAC systems.Explosion-Proof Cable Glands & Sealing Fittings

Prevent gas ingress through wiring entries.Intrinsically Safe Interface Hardware

Used for low-energy sensors like thermostats and pressure transducers.

These components form the backbone of safe, certified HVAC control systems for hazardous industrial facilities. While full control panels are often custom-built, the certified elements available through Intrinsically Safe Store ensure compliance with NEC, ATEX, and IECEx requirements.

What Are the Best Explosion-Proof HVAC Panel Options by Industry?

| Industry | Recommended Panel Type | Certifications | Notes |

|---|---|---|---|

| Oil & Gas | Flameproof Class I Div 1 | UL 1203 | With purge systems for cabins |

| Chemical Plants | ATEX Zone 1 | Ex d / Ex p | Corrosion-resistant enclosures |

| Pharmaceuticals | Zone 2 / Div 2 | Ex nA / NEMA 4X | Washdown safe |

| Food & Beverage | Dust hazard (Zone 21) | Ex t | Stainless steel IP69K |

| Manufacturing | Div 2 | Non-incendive / NEMA 4 | Cost-effective |

Frequently Asked Questions (FAQs)

What is the difference between explosion-proof and intrinsically safe HVAC components?

Explosion-proof components contain ignition sources within a flameproof enclosure, while intrinsically safe components limit electrical energy to non-ignitable levels. HVAC control panels often use both, depending on the sensor and wiring type.

Do all hazardous locations require explosion-proof HVAC panels?

Not always—some Division 2 or Zone 2 areas may permit purged/pressurized panels or non-incendive control systems. Always verify the hazard classification before selecting equipment.

Can explosion-proof HVAC panels be used outdoors?

Yes, most are available with NEMA 4X or IP66/67 ratings for outdoor installation, protecting equipment from dust, water, and corrosive conditions.

How often do explosion-proof HVAC control panels need maintenance?

Most facilities conduct inspections every 6–12 months, though environments with heavy dust, salt, or chemical exposure may require quarterly checks.

Can I integrate explosion-proof HVAC control panels with modern building automation systems?

Yes—most panels support industrial network protocols such as Modbus, BACnet, or Ethernet/IP, enabling seamless integration with BAS, SCADA, or DCS systems.

Not sure which explosion-proof HVAC control panel is right for your site?

Talk to our hazardous-area specialists for panel selection, certifications, and custom quotes for your HVAC systems.

Chat with an HVAC Safety Expert Call Us: +1 (832) 699-6726 Request a Quote for HVAC Control PanelsConclusion: Why Explosion-Proof HVAC Control Panels Are Essential for Safety and Compliance

Explosion-proof HVAC control panels provide essential protection, ensuring safe and consistent temperature control in hazardous industrial locations. From flameproof enclosures to ATEX and UL certifications, these panels prevent ignition risks while delivering robust performance in high-risk environments. For any facility handling flammable gases, vapors, or combustible dusts, choosing the right explosion proof hvac control panel is not optional — it’s a critical safety requirement.

When you’re ready to upgrade or build a compliant HVAC system, explore certified components and solutions at Intrinsically Safe Store for reliable, engineered safety.