Industrial inspections in hazardous environments have traditionally required human entry into confined spaces, elevated structures, or areas containing explosive gases or dusts. This approach carries significant risks and often demands costly shutdowns. The emergence of the ATEX certified inspection drone has transformed inspection workflows across oil & gas, petrochemical, energy, pharmaceuticals, mining, wastewater, and manufacturing sectors.

ATEX-certified drones enable safe, remote visual inspection inside explosive atmospheres, dramatically reducing risk, downtime, and operational costs. This in-depth article explores how ATEX drone technology works, which certifications apply, the safety standards involved, and the expanding use cases across critical industries.

What Is an ATEX Certified Inspection Drone?

An ATEX certified inspection drone is an unmanned aerial vehicle designed and approved for operation in explosive atmospheres. These drones comply with European ATEX directives, meaning they are engineered to prevent ignition from electrical components, heat, static discharge, or mechanical failure.

ATEX drones are used to inspect hazardous areas where:

Flammable gases or vapors are present

Combustible dusts create explosive risk

Human entry would be unsafe

Continuous monitoring is required

This makes them essential tools for industries that rely on regular maintenance inspections but must avoid ignition risks.

Need certified devices to support your ATEX drone inspections?

Pair your ATEX inspection drone with intrinsically safe cameras, tablets, and phones for data capture, reporting, and remote collaboration in hazardous areas.

Browse Explosion Proof & ATEX Cameras Intrinsically Safe Tablets Intrinsically Safe Cell Phones

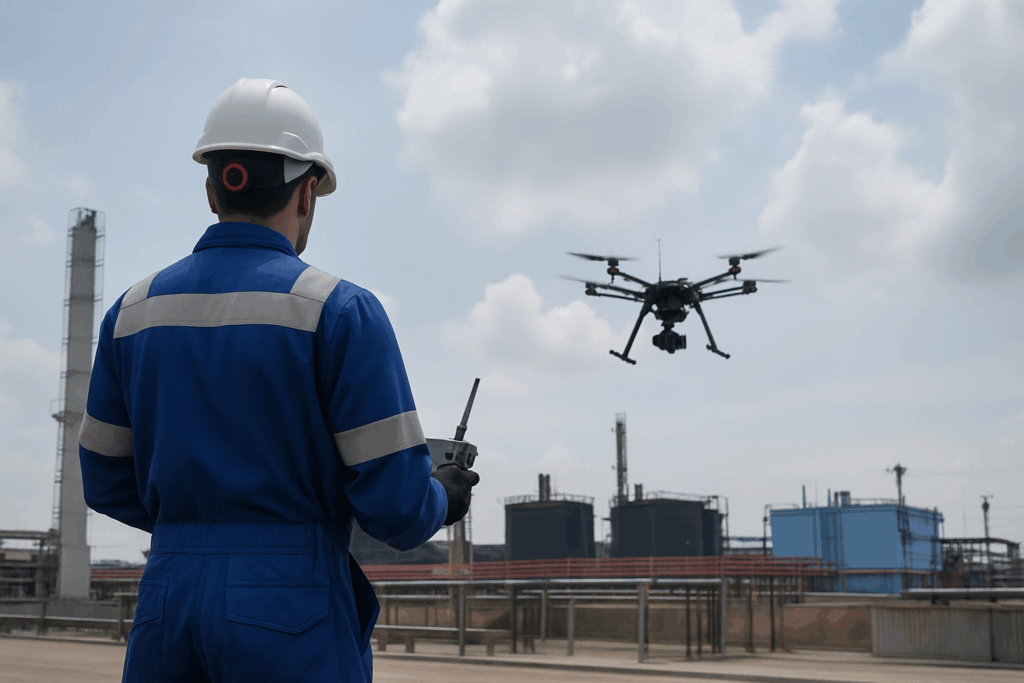

Why Are Drones Used in Hazardous Industrial Environments?

Traditional inspection practices often require workers to enter dangerous spaces, erect scaffolding, use rope access systems, or shut down equipment. These activities introduce safety hazards and slow productivity.

Drones eliminate many of these challenges by delivering:

Remote inspection capability without human exposure

High-resolution imaging, thermal mapping, and 3D modeling

No need for shutdowns in many cases

Faster inspection times

Lower operational costs

Reduced confined-space entry requirements

When a drone is ATEX certified, it can operate in explosive areas where unapproved devices would be prohibited.

What ATEX Certifications Apply to Inspection Drones?

ATEX certification is required for any electronic device used in explosive atmospheres in Europe. Drones must comply with ATEX Directive 2014/34/EU and meet specific equipment group and category designations.

Below are the relevant ATEX classifications.

ATEX Equipment Groups

Group I – Mining environments

Group II – Above-ground industrial environments

ATEX certified inspection drones are typically Group II devices.

ATEX Hazard Zones

For gas (G) and dust (D) environments:

Zone 0 – Continuous or long-term exposure

Zone 1 – Likely exposure during normal operation

Zone 2 – Hazard present only occasionally

Zone 21/22 – Combustible dust environments

Most inspection drones are certified for Zone 1 or Zone 2, but some highly specialized units are approved for Zone 0 applications.

ATEX Protection Concepts for Drones

Drones must incorporate multiple ignition-prevention controls, including:

Limited surface temperature

Anti-static materials

Intrinsically safe circuitry

Sealed propulsion systems

Explosion-proof housing around critical electronics

Protected batteries with thermal and electrical safety systems

Certification ensures the drone cannot ignite any surrounding hazardous atmosphere.

Want to go deeper into ATEX, IECEx and Class/Division standards?

These guides explain how global hazardous-area certifications work so you can select the right ATEX drone and supporting equipment with confidence.

ATEX vs IECEx What Is ATEX Certification? IECEx Intrinsically Safe Devices Class I Div 1 vs Div 2 Intrinsically Safe vs Explosion-ProofHow Do ATEX Certified Inspection Drones Enhance Safety?

Safety is the core reason ATEX drones exist. Operating a traditional drone in an explosive atmosphere poses multiple ignition risks such as motor sparks, battery thermal runaway, or static electricity discharge. ATEX certification ensures these risks are eliminated or controlled.

Key safety advantages include:

Zero Ignition Risk

ATEX-certified drones are engineered so that electrical or mechanical components cannot ignite a flammable atmosphere. This lowers the risk of explosions during inspection.

Reduced Human Entry

Inspections that once required people to enter tanks, vessels, flare stacks, chimneys, or confined spaces can now be performed remotely.

Real-Time Monitoring

Drones offer continuous visual and sensor-based feedback, allowing early detection of structural issues, leaks, corrosion, or thermal anomalies.

Emergency Response Readiness

ATEX drones are frequently deployed after safety incidents to evaluate conditions before sending personnel into hazardous zones.

What Technology Do ATEX Certified Inspection Drones Use?

ATEX drones integrate advanced imaging and sensing tools to provide full inspection capability without human intervention.

Common technologies include:

High-Resolution Visual Cameras

Used for corrosion detection, weld inspection, structural integrity assessment, and measurement of surface degradation.

Thermal Imaging Sensors

Infrared cameras help detect:

Hotspots

Electrical anomalies

Process irregularities

Leaks in thermal systems

LiDAR Mapping

Three-dimensional mapping supports:

Structural modeling

Digital twin creation

Precision measurements

Tunnel and confined-space inspections

Collision-Avoidance Systems

Hazardous environments often involve tight spaces. ATEX drones use:

Multi-directional sensors

SLAM navigation

Obstacle avoidance algorithms

Enclosed Rotor and Propulsion Systems

Unlike conventional drones, ATEX units often use shielded or enclosed rotors to prevent mechanical sparks or object impact.

For ground-based inspection and support, you can also use explosion proof and ATEX cameras, intrinsically safe device cases, and intrinsically safe tablets to review footage, capture data and document findings directly in hazardous areas.How Are ATEX Certified Inspection Drones Used in Industrial Settings?

The use cases for ATEX drones have expanded significantly as technology improves. Below are the most common applications across high-risk industries.

Use Cases in Oil & Gas Facilities

Oil & gas operations include some of the most hazardous environments on the planet, making ATEX drones ideal for safe inspections.

Tank and Vessel Inspections

Drones inspect:

Floating roofs

Internal tank walls

Residue buildup

Corrosion

Internal framing structures

This reduces the need for scaffolding or shutdowns.

Flare Stack and Chimney Inspection

ATEX drones capture real-time images of:

Burners

Pipes

Guy wires

Refractory lining

Inspections can occur while equipment remains in operation.

Pipeline Monitoring

Drones detect:

Coating damage

Corrosion

Vegetation encroachment

Heat signatures indicating leaks

Offshore Platforms

On offshore rigs, ATEX drones reduce exposure to:

High-pressure systems

Explosive gases

Hard-to-access structures

Use Cases in Chemical and Petrochemical Plants

Chemical plants involve complex processes with flammable solvents, powders, and gases. ATEX drones enhance operational safety by enabling inspections without exposure.

Reactor and Column Inspections

Drones can enter confined processing equipment to assess conditions internally.

Dust Hazard Monitoring

For facilities handling powders or granules, ATEX drones identify:

Dust accumulation

Static charge risk

Filtration-system damage

Building and Structural Integrity Checks

Drones evaluate roofs, walls, piping racks, platforms, and structural steel for early signs of degradation.

Use Cases in Other High-Risk Industrial Sectors

ATEX certified inspection drones are also widely used in:

Mining

Monitoring conveyor tunnels, ventilation shafts, and explosive dust-prone zones.

Pharmaceuticals

Inspecting rooms with fine powders prone to combustible dust formations.

Wastewater Treatment

Evaluating gas-rich digesters and confined areas with methane exposure.

Food Processing

Monitoring sugar, flour, and grain dust facilities, which can present explosive dust hazards.

What Are the Advantages of Using ATEX Certified Inspection Drones?

ATEX drones are becoming a standard tool across industries because of measurable operational advantages.

Reduced Downtime

Inspections can often occur while systems remain active.

Lower Cost

Eliminates scaffold erection, rope access, confined-space entry teams, and system shutdowns.

Enhanced Worker Safety

Removes personnel from hazardous, toxic, or explosive environments.

Better Data Quality

High-resolution imaging and continuous monitoring provide more accurate and complete data than manual methods.

Repeatability

Automated flight paths support routine, standardized inspections.

Comparison Table: ATEX Certified vs. Non-ATEX Drones

| Feature | ATEX Certified Drone | Non-ATEX Drone |

|---|---|---|

| Ignition Prevention | Yes | No |

| Hazardous Area Use | Zone 0, 1, 2, 21, 22 | Not permitted |

| Enclosed Components | Yes | No |

| Intrinsic Safety | Yes | No |

| Suitable for Oil & Gas | Yes | Limited |

| Confined-Space Use | Safe | Unsafe |

| Certification Documentation | Required | Not provided |

Frequently Asked Questions (FAQs)

Can a standard drone be used in a hazardous environment?

No. Standard drones pose ignition risks due to electrical sparks, static discharge, and battery heating. Only ATEX certified inspection drones are approved for explosive atmospheres.

Are ATEX drones intrinsically safe?

Many ATEX drones incorporate intrinsically safe design principles, but true intrinsic safety certification depends on the specific model. They must meet ATEX requirements for ignition prevention.

Can ATEX drones operate in confined spaces?

Yes. Many ATEX drones are designed for tight, enclosed, and GPS-denied environments using SLAM technology and collision-avoidance sensors.

What industries use ATEX inspection drones the most?

Common industries include oil & gas, petrochemical, mining, wastewater treatment, pharmaceutical manufacturing, and food processing.

Do ATEX drones require special training?

Operators typically require drone pilot certification, as well as hazard-awareness training for explosive atmospheres. Some organizations also require confined-space or process-safety training.

Planning to deploy ATEX inspection drones at your facility?

Our hazardous-area specialists can help you choose compatible cameras, control devices, lighting and gas detectors for a fully compliant inspection workflow.

Chat with a Safety Expert Call Us: +1 (832) 699-6726 Intrinsically Safe Portable Lighting Intrinsically Safe Gas DetectorsConclusion: Why ATEX Certified Inspection Drones Are Essential for Hazardous Industrial Facilities

ATEX certified inspection drones have become vital tools for safe, efficient, and cost-effective inspection in explosive industrial environments. By eliminating ignition risks, reducing human exposure, and delivering high-quality data, the atex certified inspection drone is transforming operational safety across multiple sectors. From oil & gas refineries to chemical plants and dust-hazard facilities, these drones offer unmatched advantages in reliability, safety compliance, and inspection performance.

As industries continue prioritizing worker safety and operational efficiency, ATEX-certified drones will remain an essential component of modern industrial inspection strategies.