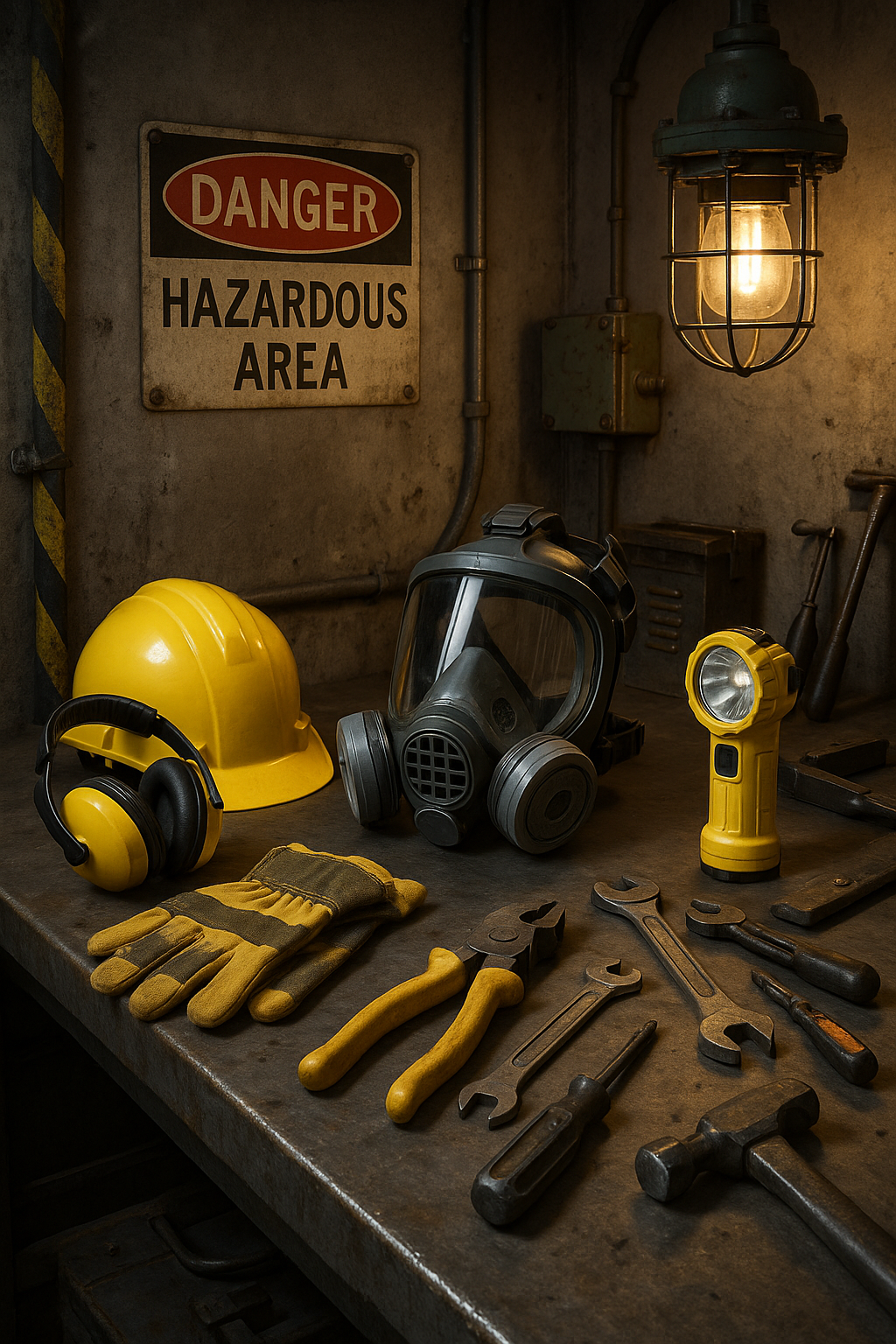

As 2025 draws to a close, the pressure is on for EHS managers, procurement officers, and operations leaders in hazardous environments to make the most of their remaining budget. This is the perfect time to invest in upgrading your hazardous area gear, ensuring compliance and safety in your operations. With the right equipment, you can enhance productivity while safeguarding your team.

In this article, we’ll explore why year-end budget spending is crucial for upgrading your hazardous area gear and what you should prioritize. We’ll also provide a quick buying checklist and highlight common mistakes to avoid. Let’s dive in!

Why Year-End Budget is the Best Time to Upgrade Hazardous-Area Gear

Year-end budget spending is not just a financial necessity; it’s an opportunity to enhance safety and efficiency in your operations. Many organizations find themselves with surplus funds as the fiscal year closes, making it an ideal time to invest in new equipment. Upgrading your hazardous area gear can lead to improved compliance with safety regulations, such as ATEX and IECEx standards, which are critical in environments classified as Class I Division 1, Class I Division 2, Zone 1, and Zone 2.

Moreover, investing in intrinsically safe equipment can significantly reduce the risk of accidents and enhance operational efficiency. This is particularly important in industries like oil & gas, chemicals, and manufacturing, where the stakes are high. By prioritizing your last-minute budget spending, you can ensure that your team is equipped with the best tools for the job.

What to Prioritize with Last-Minute Budget Spending

When considering your year-end purchases, focus on the following key areas:

- Portable Lighting: Essential for visibility in hazardous areas.

- Gas Detection / Measurement & Calibration: Critical for monitoring air quality and ensuring safety.

- Communications Equipment: Vital for maintaining contact in emergency situations.

- Cameras: Useful for inspections and monitoring hazardous environments.

- Power/Energy Solutions: Ensure reliable power sources for all equipment.

Portable Lighting

Portable lighting is crucial for ensuring visibility in hazardous areas. Look for intrinsically safe models that comply with relevant safety standards. These lights should be durable, easy to transport, and capable of providing adequate illumination in low-light conditions.

Gas Detection / Measurement & Calibration

Investing in reliable gas detection equipment is non-negotiable. Ensure that the devices you choose are certified for use in hazardous environments and can accurately measure various gases. Regular calibration is essential to maintain accuracy and compliance.

Communications

Effective communication is vital in hazardous environments. Invest in intrinsically safe communication devices that allow your team to stay connected, especially in emergencies. Look for options that offer clear audio quality and durability.

Cameras

Using cameras for inspections can enhance safety and efficiency. Choose models that are designed for hazardous areas and can withstand harsh conditions. These cameras can help in monitoring operations and ensuring compliance with safety standards.

Power/Energy

Reliable power sources are essential for all your equipment. Consider investing in intrinsically safe power solutions that can operate safely in hazardous environments. Ensure that these solutions are compatible with your existing gear.

A Quick “48-Hour” Buying Checklist for Procurement/EHS

To streamline your purchasing process, use this quick checklist:

- Identify your budget and prioritize needs.

- Research suppliers and compare products.

- Check for compliance with ATEX, IECEx, and other relevant standards.

- Review lead times and availability.

- Ensure all necessary accessories are included.

- Finalize orders and confirm delivery dates.

Common Mistakes to Avoid

When upgrading your hazardous area gear, be mindful of these common pitfalls:

- Choosing the Wrong Rating: Ensure that all equipment is rated for the specific hazardous area classification.

- Missing Certifications: Verify that all products have the necessary certifications for safety compliance.

- Ignoring Lead Times: Plan ahead to avoid delays in receiving critical equipment.

- Overlooking Accessories: Don’t forget to order necessary accessories that may be required for operation.

FAQs

What is intrinsically safe equipment?

Intrinsically safe equipment is designed to prevent ignition in hazardous environments by limiting energy levels.

What are ATEX and IECEx certifications?

These are safety standards that ensure equipment is safe for use in explosive atmospheres.

How do I know if my equipment is compliant?

Check for certification labels and documentation from the manufacturer.

What should I consider when purchasing gas detection equipment?

Look for accuracy, reliability, and compliance with safety standards.

Why is portable lighting important in hazardous areas?

It ensures visibility and safety for workers in low-light conditions.

Conclusion

As the year comes to a close, now is the time to act. Upgrading your hazardous area gear not only enhances safety but also ensures compliance with industry standards. Don’t let your budget go to waste—make informed purchases that will benefit your operations in the long run. Act now to secure the best equipment for your team!