Description

IS-TH-PP Intrinsically Safe Polypropylene Tank Alarm – High Level, 10″ to 60″ Depths

The IS-TH-PP Series Intrinsically Safe Tank Alarm is a battery-powered high-level alarm designed for hazardous-area tank monitoring where plastic construction and broad chemical compatibility are required. Built for Class I Division 1 and Zone 0 locations, this alarm combines a bright flashing LED with a loud 101 dB warbling buzzer to warn operators when the tank reaches a critical high-level condition.

Each unit includes an intrinsically safe lithium battery pack with years of operational life, a dedicated low-battery alert, and a silencing/test button to support routine checks. With multiple probe lengths from 10″ to 60″, the IS-TH-PP Series is ideal for non-metallic tanks, day tanks, and sumps handling corrosive or aggressive chemicals.

Key Features:

✅ Intrinsically Safe design for Class I, Div. 1 and Zone 0 hazardous locations

✅ High-level alarm to prevent tank overfills and spills

✅ Battery powered – no external power wiring required for the basic alarm

✅ 101 dB warbling buzzer plus bright LED for unmistakable alerts

✅ Polypropylene (PP) wetted construction for excellent chemical resistance

✅ Multiple depth options from 10″ to 60″ to match tank geometry and setpoints

✅ Silence/test button for operator acknowledgement and quick functional testing

✅ Separate low-battery alert to differentiate power status from level conditions

✅ Optional relay output for connection to PLCs or safe-area annunciators via I.S. barrier

📦 Package Options (High-Level PP Depth Variants):

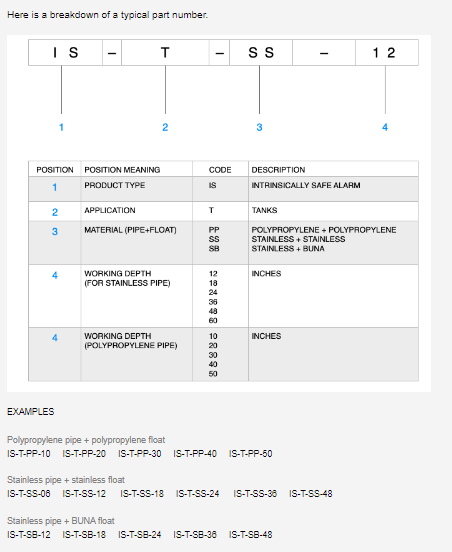

🔹 IS-TH-PP-10 – 10″ depth, Polypropylene high-level intrinsically safe tank alarm

🔹 IS-TH-PP-20 – 20″ depth, Polypropylene high-level intrinsically safe tank alarm

🔹 IS-TH-PP-30 – 30″ depth, Polypropylene high-level intrinsically safe tank alarm

🔹 IS-TH-PP-40 – 40″ depth, Polypropylene high-level intrinsically safe tank alarm

🔹 IS-TH-PP-50 – 50″ depth, Polypropylene high-level intrinsically safe tank alarm

🔹 IS-TH-PP-60 – 60″ depth, Polypropylene high-level intrinsically safe tank alarm

Optional Accessories (sold separately):

🔸 Relay Output Module for safe-area or PLC interface (with appropriate intrinsic safety barrier)

🔸 Spare Intrinsically Safe Battery Pack

🔸 Control drawing, operating modes chart, and battery datasheet

🔸 Certificate of Conformance (CoC) and installation instructions

IS-TH-PP Technical Specifications:

| Specifications: | |

| Stainless float switch S.G | 0.75 |

| Polypropylene float switch S.G | 0.6 |

| Enclosure material | Aluminum (painted) |

| Operating temp (ambient) | (-40 to 60ºC (-76-140ºF) |

| Maximum temp. (liquid) | 149ºC [300ºF] |

| Buzzer volume | 101dB @ 2ft. |

| Battery capacity | 2400 mA-hr |

| Ingress protection | IP65 |

| Lens material | Lexan |

| Stainless steel | 316 except float retaining rings (type PH 15-7 Mo) |

| Current consumption during alarm | 30mA |

| Relay current | 80mA max. |

| Battery chemistry | Lithium Thionyl Chloride |

| Battery pack voltage | 7.2VDC |

| Lithium weight | 1.2g (per pack of 2 cells) |

| Cable capacitance (if applicable) | 30pf/ft |

| Cable inductance (if applicable) | 0.2mH/ft |

|---|

Certifications & Compliance:

CSA has certified this unit to the following standards:

- CERTIFICATE OF CONFORMANCE

- CSA CAN/CSA C22.2 No. 0-10

- CSA CAN/CSA-22.2 No. 60079-0-15

- CSA CAN/CSA-22.2 No. 60079-11-14

- CSA CAN/CSA-22.2 No. 1010-1012

- C22.2 No. 60529:16

- ANSI/ISA-60079-0 (12.00.01)-2013

- ANSI/ISA 60079-11 (12.02.01)-2014

- ANSI/UL 61010-1, 3rd Ed.

- UL913, 8th Ed.

Markings:

Ex ia IIB T4 Ga

Class I, Zone 0, AEx ia IIB T4 Ga

Class I, Div. 1 Groups C and D T4, IP65

CSA File number: 263009

Chemical & Mechanical Design:

The IS-TH-PP Series uses Polypropylene construction for the wetted components, providing excellent resistance to many aqueous chemicals and corrosive fluids. Polypropylene is suitable for temperatures up to approximately 200°F (93°C). For applications requiring alternative materials such as PTFE or Kynar, consult the manufacturer’s chemical resistance data and contact our team for custom options.

Applications of IS-TH-PP Intrinsically Safe Tank Alarms:

🔹 High-level protection on non-metallic and plastic tanks in hazardous areas

🔹 Chemical storage tanks handling acids, bases, and process chemicals

🔹 Day tanks and dosing tanks in oil & gas, chemical, and water treatment plants

🔹 Sumps and pits requiring overfill protection in Class I Div. 1 classified areas

🔹 Industrial and utility tanks where PP wetted materials are preferred over stainless steel

What’s in the Box?

📦 1× IS-TH-PP Intrinsically Safe Tank Alarm (selected depth variant)

📦 1× Intrinsically Safe Lithium Battery Pack (installed or included)

📦 1× Installation & Operating Instructions

📦 Optional: Relay Output Module, CoC, and wiring documentation if ordered

Ordering & Shipping Details

📦 Lead Time: Typically 1–2 weeks depending on model and configuration

📍 Shipping: Worldwide shipping with standard and expedited options

💳 Payment Options: Credit Card, PayPal, Wire Transfer, and Net Terms for approved customers

🛠️ Technical Support: Our hazardous-area specialists are available to assist with depth selection, alarm orientation, and integration with your control system

FAQs:

What is the difference between the 10″–60″ depth options?

Each model number (IS-TH-PP-10, -20, -30, -40, -50, -60) corresponds to a specific probe length, positioning the float at the desired high-level alarm point. Choose the depth that matches where you want the alarm to trigger inside your tank.

Is the IS-TH-PP suitable for Class I Division 1 hazardous locations?

Yes. The IS-TH-PP Series is designed and certified for use in hazardous locations when installed and connected according to the manufacturer’s documentation and intrinsic safety practices.

Can this alarm be connected to a PLC or remote alarm panel?

Yes. When equipped with the optional relay output module and used with an appropriate intrinsic safety barrier, the alarm can be interfaced to PLCs, DCS, or remote annunciator panels located in safe areas.

When should I choose PP instead of stainless steel?

Choose PP for many aqueous chemicals and corrosive solutions where plastic wetted parts provide better compatibility than stainless steel. For hydrocarbon service or where metal construction is preferred, consider the IS-T-SS stainless steel series.

What others are saying

There are no contributions yet.