When it comes to safety in hazardous environments, intrinsically safe equipment plays a crucial role. Designers create these devices to prevent ignition of flammable substances, thereby ensuring the safety of workers and the environment. At the Intrinsically Safe Store, we understand the importance of these devices and the rigorous testing procedures they must undergo for certification. In this article, we delve into the necessary testing procedures for intrinsically safe equipment certification. We invite you to explore our website to learn more about our range of certified intrinsically safe products.

What is Intrinsically Safe Equipment?

Intrinsically safe equipment is a term that refers to devices designed to operate safely in hazardous environments where flammable gases, dust, or vapors could potentially be present. These devices limit the electrical and thermal energy to a level below what would be required to ignite a specific hazardous atmospheric mixture.

Importance of Intrinsically Safe Equipment Certification

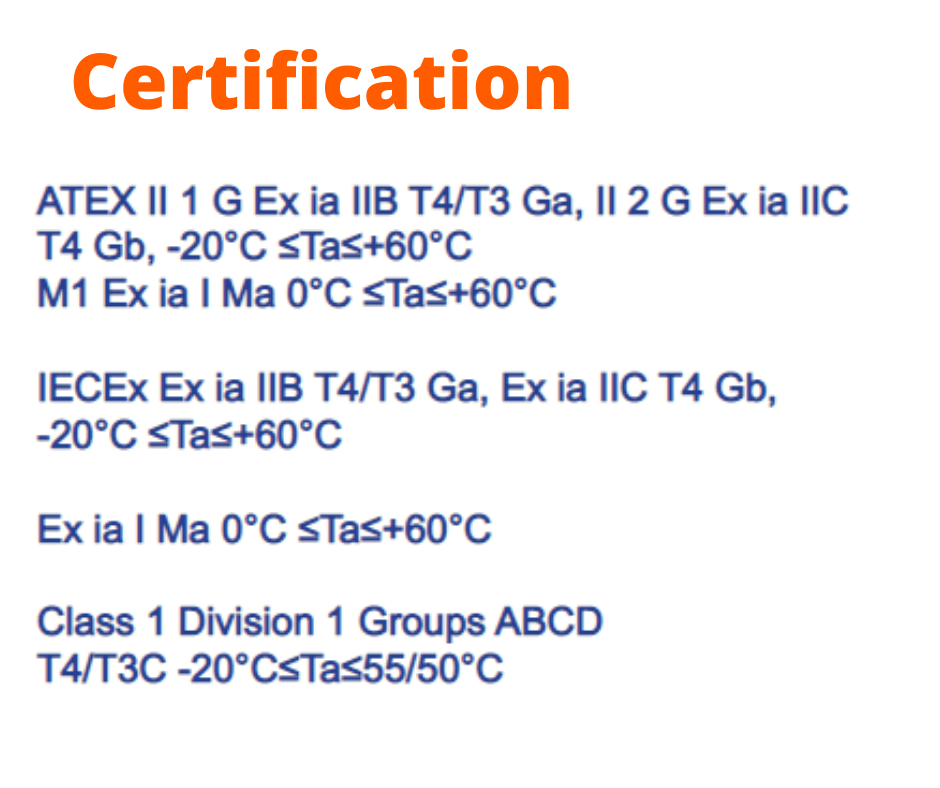

Certification of intrinsically safe equipment is crucial to ensure that these devices can safely operate in hazardous environments without causing an explosion. This certification process involves rigorous testing procedures to verify that the equipment meets the necessary safety standards.

Testing Procedures for Intrinsically Safe Equipment Certification

The testing procedures for intrinsically safe equipment certification are comprehensive and rigorous. They include:

- Temperature Testing: This test checks whether the device can operate safely at different temperatures without causing ignition.

- Electrical Testing: This test verifies that the device can limit electrical energy to prevent ignition.

- Impact and Drop Testing: This test ensures that the device can withstand physical impact without causing an explosion.

- Environmental Testing: This test checks the device’s performance under different environmental conditions such as humidity, pressure, and dust.

Case Study: Intrinsically Safe Equipment Certification

A case study that illustrates the importance of these testing procedures involves a gas detection device. The device underwent rigorous testing procedures, including temperature, electrical, impact, and environmental testing. The device successfully passed all tests, earning its intrinsically safe certification. This certification provided assurance that the device could safely operate in hazardous environments without causing an explosion.

Certifying Intrinsically Safe Equipment

In conclusion, the certification of intrinsically safe equipment involves rigorous testing procedures to ensure that these devices can safely operate in hazardous environments. These tests include temperature testing, electrical testing, impact and drop testing, and environmental testing. At the Intrinsically Safe Store, we offer a wide range of certified intrinsically safe products that have undergone these rigorous testing procedures. We invite you to contact us for more information about our products and services.