Calibration ensures intrinsically safe (IS) equipment delivers accurate readings while maintaining safety compliance—crucial in industries like oil & gas, petrochemical, and mining. Following how to calibrate intrinsically safe devices properly protects personnel, supports regulatory adherence, and extends equipment lifespan. This guide walks you through each step: preparation, environment setup, calibration execution, verification, and documentation. Whether you’re a technician or supervisor, you’ll gain the confidence and structure to perform precise and safe calibrations in hazardous environments.

Need certified calibration tools? Explore intrinsically safe gear for hazardous zones to ensure compliance.

What Is Intrinsically Safe Calibration and Why Does It Matter?

Intrinsic safety (Ex i) ensures electrical and thermal energy remain below ignition levels for explosive atmospheres—defined in IEC 60079‑11. Calibration of IS instruments—like pressure transmitters and temperature sensors—requires tools that preserve these safety limits. Calibrating with non‑IS equipment or under uncontrolled conditions risks violating certification and compromising safety. Proper calibration maintains measurement accuracy and minimizes ignition hazards, making it essential for both safety and compliance.

What Standards Govern Intrinsically Safe Calibration?

IS calibration follows international standards including:

IEC 60079‑11: Defines intrinsic safety design and testing

ATEX Directive 2014/34/EU: Certification across Europe for IS equipment

IECEx: International certification matching IEC 60079 standards

Understanding zone classification is also critical:

Zone 0: Continuous presence of explosive atmosphere

Zone 1: Likely presence during operation

Zone 2: Unlikely, but possible under abnormal conditions

Calibration devices must carry marking like Ex ia IIC T4 Ga, showing approval for specific zones and gas groups.

See our full guide on IECEx vs. ATEX certifications to better understand compliance.

What Tools Do You Need to Calibrate IS Equipment?

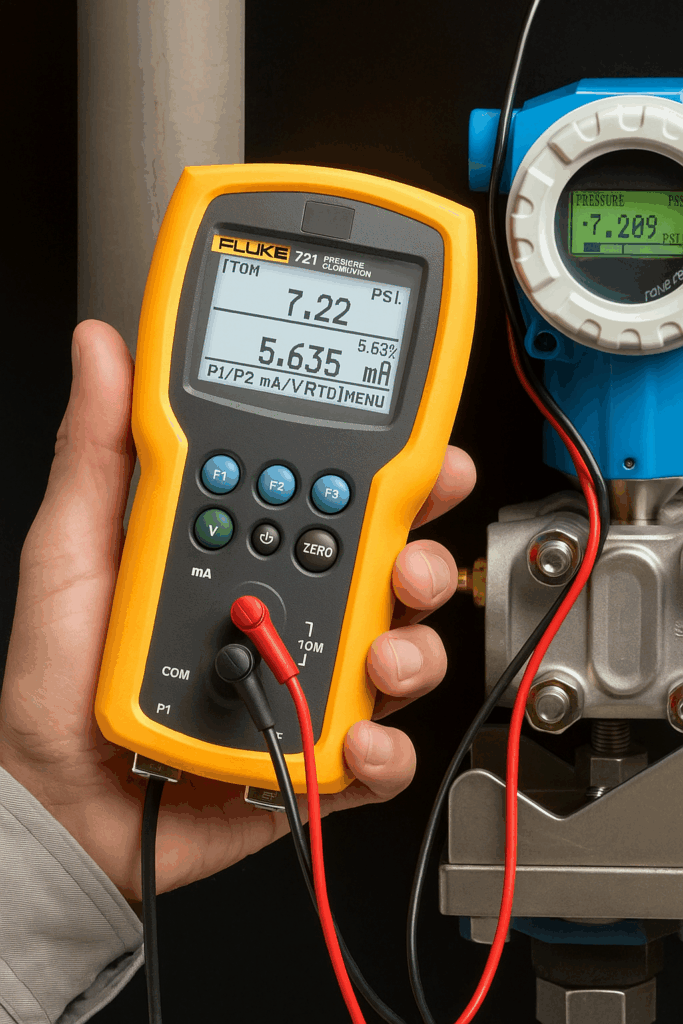

To perform safe and effective calibrations in hazardous environments, it’s essential to use intrinsically safe tools approved for explosive zones. Below are top tools available at Intrinsically Safe Store:

Fluke 725Ex Intrinsically Safe Calibrator

Type: Multifunction calibrator

Certification: ATEX/IECEx certified for Zone 1

Functions: 4–20 mA current, voltage, frequency, RTD, and thermocouple simulation

Best Use: Versatile calibration of transmitters and sensors in hazardous locations

Ecom Fluke 28 II EX Multimeter

Type: Intrinsically safe digital multimeter

Certification: ATEX, IECEx, UL, and CSA (Class I Div 1)

Functions: Measures voltage, current, resistance, frequency, and continuity

Best Use: Electrical diagnostics and equipment verification

Ecom Fluke 568 EX Infrared Thermometer

Type: Non-contact infrared thermometer

Certification: ATEX and IECEx approved

Functions: Measures temperatures from -40°C to +800°C with laser targeting

Best Use: Surface temperature checks without direct contact

These certified devices offer reliability, compliance, and safety for technicians operating in ATEX-rated environments.

How Do You Prepare the Calibration Setup?

Check certification: Ensure both calibrator and device are marked for appropriate zones.

Review history: Obtain previous calibration reports, device specs, and manuals.

Inspect equipment: Review physical condition, labels, seals, and calibration status.

Gather supplies: Certified hoses, pressure pumps, thermocouple leads, and test cables.

Log preparation: Start digital or paper calibration form with relevant details.

How Do You Set Up the Environment and Safety Controls?

Verify zone: Confirm the declared hazardous zone and eliminate potential ignition sources.

Use certified barrier: Ensure all equipment complies with energy-limiting safety standards.

Wear proper PPE: Utilize non-sparking tools, antistatic clothing, and protective glasses.

Stabilize environment: Maintain optimal temperature and humidity for calibration.

How to Perform Calibration

Current (4–20 mA) Calibration

Connect the calibrator to the transmitter loop. Execute zero/span checks, generate signals, and measure device response. Adjust as needed and repeat to confirm stability.

Pressure Calibration

Use IS-rated pressure calibrators or modules. Apply pressure increments (e.g., 0%, 25%, 50%, 75%, 100%) and record outputs. Adjust devices as necessary.

Temperature Calibration

Connect temperature simulator or infrared thermometer. Validate output across nominal temperature points and record any offsets. Calibrate accordingly.

Digital Fieldbus (HART/FF)

Use communication-enabled calibrators (if supported). Connect to the device and calibrate using auto-trim or manual entry per protocol.

How Do You Verify Calibration Results?

Perform independent verification with secondary standards.

Calculate measurement error and uncertainty.

Compare with acceptable tolerance and determine pass/fail status.

Repeat calibration if outside acceptable limits.

How to Document and Certify Calibration

Proper documentation includes:

Device details: serial number, model, zone certification

Environmental conditions: temperature, humidity, technician

Calibration results: applied points, raw/adjusted readings

Tool references: calibrator ID, certificate, calibration date

Keep all records in digital or physical formats for audits and traceability.

How Often Should You Calibrate Intrinsically Safe Devices?

Typical intervals range from 6 to 12 months. However, calibration frequency should be adjusted based on:

Equipment usage

Environmental stress

History of drift or failure

Regulatory requirements (e.g., ISO/IEC 17025)

What Common Pitfalls Should You Avoid?

Using non-IS certified tools

Skipping barrier checks or ignoring markings

Failing to record environmental conditions

Omitting pre/post checks

Poor documentation practices

Training and SOPs mitigate these risks and ensure repeatable, safe calibration.

Calibration Tools Comparison Table

| Tool | Type | Functions | Zone Rating | Best Use Case |

|---|---|---|---|---|

| Fluke 725Ex Calibrator | IS Multifunction Calibrator | 4–20 mA, voltage, RTD, thermocouples | Zone 1 | Broad calibration in industrial zones |

| Ecom Fluke 28 II EX Multimeter | IS Digital Multimeter | Electrical testing and diagnostics | Class I Div 1 | Maintenance and safety checks |

| Ecom Fluke 568 EX Thermometer | IR Thermometer | Surface temp (non-contact) | ATEX/IECEx | Spot temperature verification |

Want expert help choosing the right calibration tool? Schedule a free consultation with a hazardous area specialist.

FAQs

What makes a calibrator intrinsically safe?

It must limit voltage and current to non-ignition levels, even during faults. Certified markings like Ex ia IIC confirm suitability for hazardous zones.

Can I use standard calibrators with barriers?

Yes, if barriers are certified and correctly implemented. However, this setup is less convenient and can complicate mobile calibrations.

What documentation is needed after calibration?

Include serial numbers, environmental data, technician info, results, and reference standards. Maintain records in secure, traceable formats.

How is calibration done in Zone 0 environments?

Only use tools rated for Zone 0 (e.g., Ex ia). Do not introduce non-IS tools or bypass certification barriers.

Can non-certified technicians perform calibration?

No. Personnel must have training such as CompEx or IEC 60079-17 certification. Untrained personnel risk invalidating IS compliance.

Conclusion

Knowing how to calibrate intrinsically safe devices is essential for safety, compliance, and equipment performance. By following a structured five-step process—from preparation through documentation—and using certified tools and trained personnel, organizations can ensure accurate and safe calibration procedures in explosive environments. Regular calibration keeps your operations reliable, auditable, and most importantly, safe.