When it comes to safety in hazardous environments, nothing is more critical than the use of Intrinsically Safe Lighting Equipment. This article, brought to you by the Intrinsically Safe Store, will delve into the certification processes that ensure these devices are safe and reliable. We invite you to visit our website to learn more about our range of certified products.

Understanding Intrinsically Safe Lighting Equipment

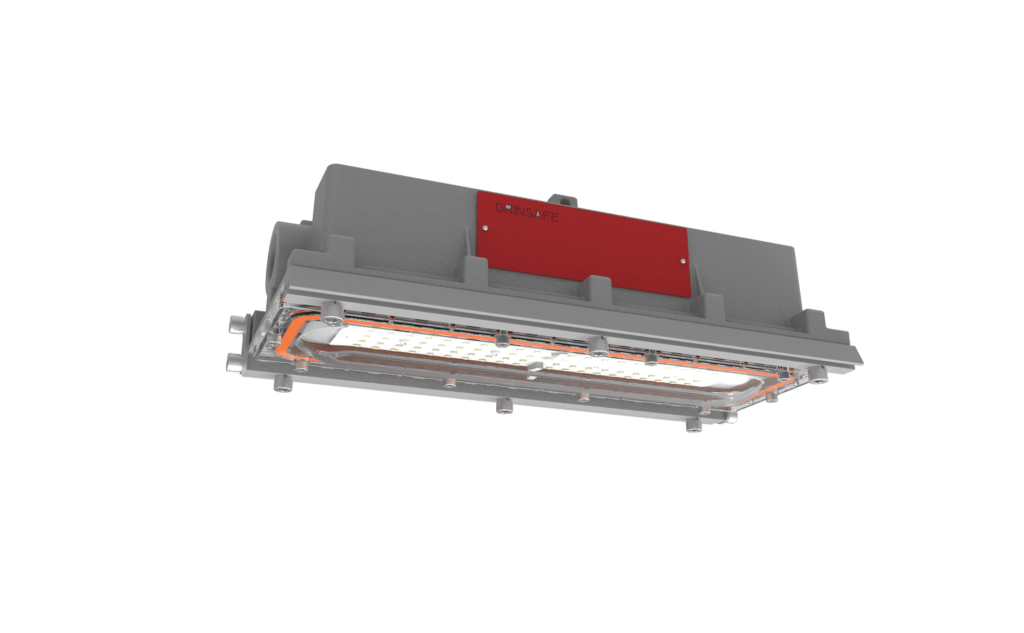

Designers create Intrinsically Safe Lighting Equipment to operate in potentially explosive atmospheres without causing ignition. These devices limit the electrical and thermal energy to a level below what would ignite a specific hazardous atmospheric mixture.

The Importance of Certification

Certification is a crucial step in the production of Intrinsically Safe Lighting Equipment. It provides assurance that the equipment meets the necessary safety standards and is safe to use in hazardous environments. Without certification, there’s no guarantee that the equipment will perform safely and effectively.

The Certification Process

The certification process for Intrinsically Safe Lighting Equipment involves several steps:

- Design Evaluation: The design of the equipment is evaluated to ensure it meets the necessary safety standards.

- Testing: The equipment undergoes rigorous testing to verify its safety and performance.

- Inspection: An inspection of the manufacturing process is conducted to ensure quality control.

- Surveillance: We carry out regular surveillance to ensure ongoing compliance with the safety standards.

Standards for Intrinsically Safe Lighting Equipment

There are several international standards that Intrinsically Safe Lighting Equipment must comply with. These include the International Electrotechnical Commission (IEC) standards, the European Union’s ATEX directive, and the United States’ National Electrical Code (NEC).

Case Study: The Certification of an Intrinsically Safe Flashlight

Consider the case of an intrinsically safe flashlight. The design of the flashlight is first evaluated against the relevant safety standards. Then, they subject it to a series of tests, including drop tests, temperature tests, and battery tests. Once the flashlight passes these tests, they inspect it to ensure that the manufacturing process meets the standard. Finally, they certify the flashlight as intrinsically safe and it becomes ready for market sale.

Certification Process for Intrinsically Safe Lighting

The certification process for Intrinsically Safe Lighting Equipment is a rigorous and essential step in ensuring the safety of those working in hazardous environments. By understanding this process, you can make informed decisions when purchasing such equipment. Remember, safety should never be compromised.

At the Intrinsically Safe Store, we commit to provide certified and reliable Intrinsically Safe Lighting Equipment. We invite you to explore our range of products and contact us if you have any questions or need further information.