As a leading provider of intrinsically safe products, Intrinsically Safe Store understands the importance of adhering to both national and international safety standards. In this article, we delve into the comparative analysis of these safety standards, specifically focusing on intrinsically safe lighting. We invite you to explore our website to learn more about our commitment to safety and quality.

Understanding Intrinsically Safe Lighting

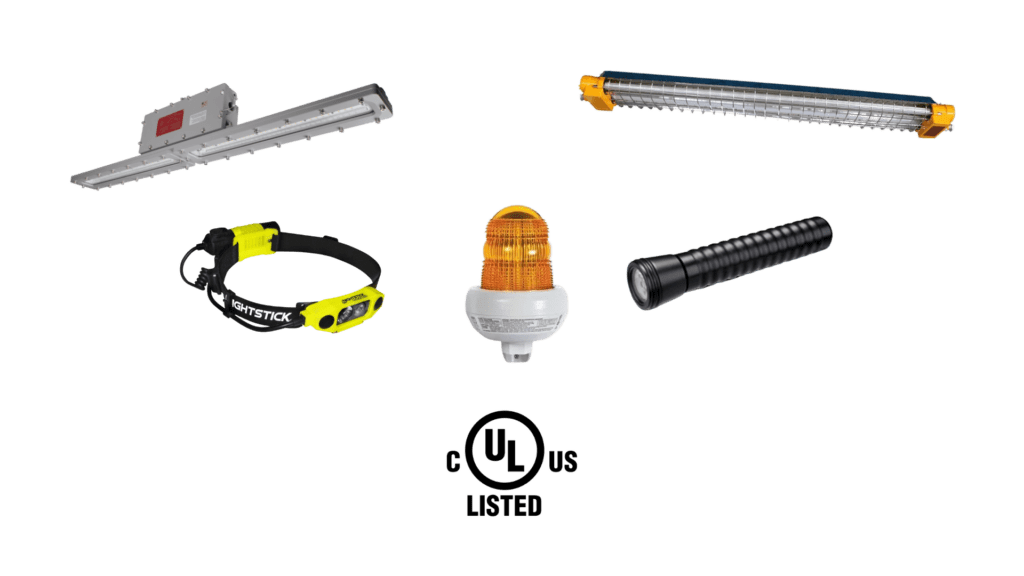

Intrinsically safe lighting is designed to operate in hazardous environments without igniting the surrounding flammable or explosive atmosphere. These lighting solutions are essential in industries such as oil and gas, mining, and chemical processing.

National Safety Standards for Intrinsically Safe Lighting

In the United States, the primary regulatory body for intrinsically safe lighting is the National Fire Protection Association (NFPA). The NFPA 70, also known as the National Electrical Code (NEC), provides guidelines for the safe installation of electrical equipment, including intrinsically safe lighting.

- The NEC classifies hazardous locations into Classes, Divisions, and Groups based on the nature and degree of the risk.

- Class I locations are those where flammable gases or vapors may be present.

- Class II locations contain combustible dust, while Class III locations have ignitable fibers or flyings.

International Safety Standards for Intrinsically Safe Lighting

Internationally, the International Electrotechnical Commission (IEC) sets the safety standards for intrinsically safe lighting. The IEC 60079 series of standards, also known as the “Explosive Atmospheres” standards, are widely accepted globally.

- The IEC standards classify hazardous areas into Zones rather than Classes and Divisions.

- Zone 0, 1, and 2 are for gas hazards, while Zone 20, 21, and 22 are for dust hazards.

Comparative Analysis of National and International Standards

While both the NEC and IEC aim to ensure the safety of intrinsically safe lighting, there are key differences between the two.

- The NEC’s classification system is more complex, with a focus on the nature and degree of the hazard. The IEC, on the other hand, uses a simpler system based on the frequency and duration of the hazardous occurrence.

- The IEC standards are more universally accepted, making them more suitable for companies operating in multiple countries.

Case Study: Intrinsically Safe Store’s Compliance with Safety Standards

At the Intrinsically Safe Store, we ensure that all our lighting products meet both national and international safety standards. For instance, our intrinsically safe lighting range is certified to both NEC and IEC standards, ensuring their safe use in various hazardous environments.

Understanding and adhering to both national and international safety standards is crucial in ensuring the safety of intrinsically safe lighting. While there are differences between the NEC and IEC standards, both aim to mitigate the risks associated with operating in hazardous environments. At the Intrinsically Safe Store, we are committed to providing products that meet and exceed these safety standards. For more information, contact us today.