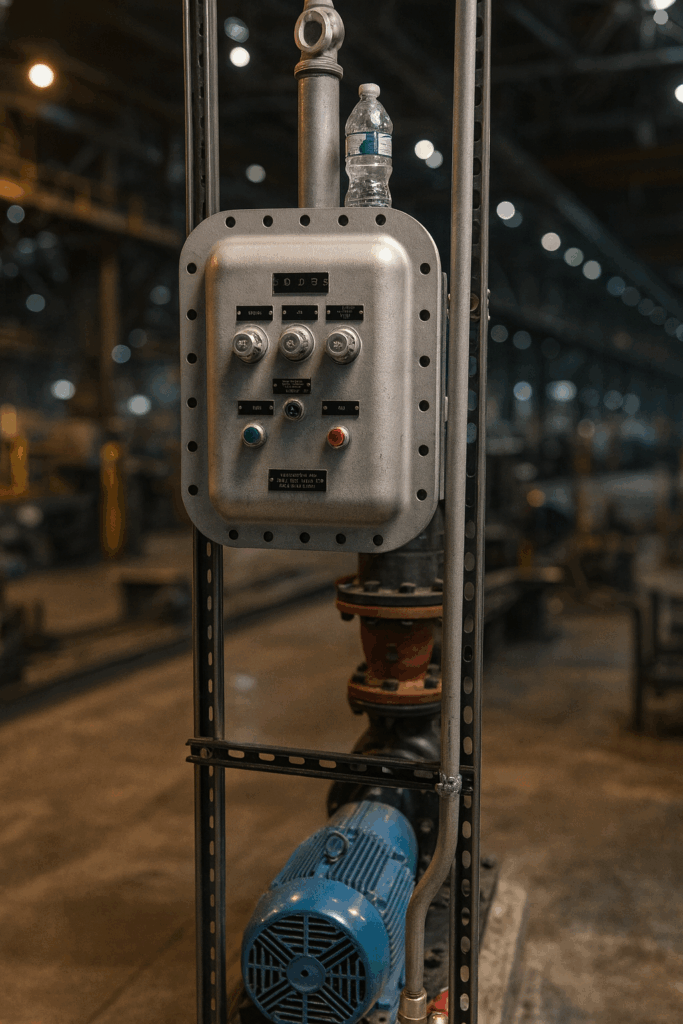

Explosion-proof control stations are essential safety components in hazardous industrial environments. Used to house switches, push-buttons, pilot lights, and control mechanisms, these stations prevent internal sparks from igniting flammable gases, vapors, or dust. If you’re researching what type of explosion proof control station you need, how much they cost, and what configurations are available, this guide breaks down everything you need to know.

This article explores certifications, enclosure types, material options, switch configurations, design options, and pricing ranges so you can confidently select the right solution for your facility.

Need Help Choosing the Right Explosion-Proof Control Station?

Our hazardous-location experts can guide you through enclosure materials, C1D1/C1D2/ATEX ratings and switch configurations.

🔶 Get a Custom QuoteWhat Is an Explosion-Proof Control Station?

An explosion-proof control station is a protective enclosure designed to contain electrical control devices in hazardous locations. These enclosures are engineered so that if an internal arc or spark ignites, the internal explosion cannot escape and ignite the external atmosphere. They are typically rated for Class I Division 1, Class I Division 2, Class II, or Zone 1/Zone 2 environments.

Explosion-proof control stations commonly contain:

Push-buttons

Selector switches

Emergency stop switches

Pilot lights

Combination control devices

Control circuit interfaces

Browse Certified Explosion-Proof Enclosures

Find rugged enclosures engineered for hazardous locations including oil, gas, chemical and process plants.

Explore Explosion-Proof Enclosures

How Do Explosion-Proof Control Stations Work?

Explosion-proof control stations operate by containing internal ignition. If a spark occurs within the enclosure, its flame path cools and quenches the explosion before it reaches the hazardous environment. These flame paths are engineered into threaded joints, flanges, covers, and conduit interfaces.

Most units also support intrinsically safe circuits, control wiring, and motor controls, making them versatile for oil & gas, chemical plants, grain handling, pharmaceuticals, wastewater facilities, and more.

Why Are Explosion-Proof Control Stations Needed in C1D1 and C1D2 Locations?

In C1D1 environments, ignitable concentrations of flammable gases or vapors exist under normal operating conditions. In C1D2 areas, they may exist only under abnormal conditions. In both cases, control devices must prevent an internal spark from igniting the surrounding environment.

Explosion-proof control stations ensure:

Regulatory compliance (OSHA, NEC/CEC, IECEx/ATEX).

Operational safety for personnel and equipment.

Minimization of ignition risks from routine control functions.

What Are the Most Common Switch and Push-Button Options?

Most explosion-proof control stations allow customization of the internal devices. Below are the most commonly selected options.

Push-Buttons

Push-buttons are the most widely used control mechanism. They are available as:

Momentary push-buttons (spring-return, typically “Start/Stop”).

Maintained push-buttons (stay latched in position).

Dual-button configurations (Start/Stop on a single assembly).

Illuminated push-buttons (status indication).

Push-buttons usually require a contact block behind the button that determines the control signal type, such as normally open (NO) or normally closed (NC).

Selector Switches

Selector switches allow operators to choose between multiple operational modes. Common configurations include:

2-position selector switch (e.g., On/Off or Local/Remote).

3-position selector switch (e.g., Off/Auto/Manual).

Key-lock selector switches (for security-controlled access).

These switches are particularly common in pump panels, conveyor systems, and process control units.

Emergency Stop (E-Stop) Switches

E-Stops are critical safety devices designed to immediately shut down equipment in emergency situations. Explosion-proof E-Stops are usually:

Mushroom-head

Maintained (twist-release mechanism)

Red with a yellow background ring

Pilot Lights

Pilot lights provide real-time visual status indications. Colors follow typical industrial standards:

Red – Fault or Stop

Green – Running or Normal

Amber – Warning

Blue/White – Specialty applications

Pilot lights may be LED-based for long life and reduced heat dissipation.

Need Junction Boxes for Your Control Devices?

Protect wiring, controls and terminations with certified explosion-proof junction boxes built for harsh environments.

Shop Junction BoxesWhat Are the Available Configurations for Explosion-Proof Control Stations?

Explosion-proof control stations are built in standardized or custom configurations depending on the number and type of devices needed. Below are the most common enclosure designs.

Single-Device Control Stations

These compact units house one push-button, switch, or pilot light. They are ideal for simple control points, such as local motor control or single-function operations.

Multi-Device Control Stations

These units house multiple devices (2–6 devices on average). Common combinations include:

Start/Stop push-buttons + pilot lights

Emergency stop + selector switch

Three-position selector switch + status indication lights

Modular Control Stations

Modular stations allow users to select independent modules and assemble them. These are more flexible and support expansions over time.

Custom Large Enclosures

Custom enclosures may house:

Multiple switches

Instrumentation displays

PLC interfaces

Motor controls

Junction boxes

These are common in refineries and offshore platforms.

Explore Power & Energy Solutions

Discover our full range of certified equipment for hazardous electrical distribution and control.

Browse Power & Energy EquipmentWhat Materials Are Explosion-Proof Control Stations Made From?

Material selection impacts safety, longevity, corrosion resistance, and cost. The most common enclosure materials include:

Aluminum Explosion-Proof Enclosures

Aluminum is the most common material due to its balance of strength, weight, and cost.

Pros:

Lightweight

Corrosion-resistant

Cost-effective

Cons:

Not suitable for highly corrosive chemical environments

Stainless Steel Explosion-Proof Enclosures

These are used in marine, chemical, pharmaceutical, and washdown-intensive environments.

Pros:

Highest corrosion resistance

Suitable for food and chemical processing

Excellent durability

Cons:

High cost

Heavier than aluminum

Glass-Reinforced Polyester (GRP) Enclosures

GRP is becoming increasingly popular due to its non-metallic advantages.

Pros:

Lightweight

Corrosion-resistant

No grounding required

Cons:

Limited high-temperature resistance

Typically used more for control panels than push-button stations

Cast Iron Enclosures

Heavy-duty and traditionally used in older systems.

Pros:

Extremely robust

Excellent mechanical protection

Cons:

Heavy

Prone to corrosion if not coated

Typically more expensive to install

How Much Does an Explosion-Proof Control Station Cost?

Explosion-proof control station pricing varies widely depending on materials, device configurations, certifications, and brand. Below is a complete pricing overview.

Typical Pricing Ranges

| Control Station Type | Typical Price Range | Includes |

|---|---|---|

| Single push-button station | $250 – $550 | Aluminum, 1 device |

| Dual push-button station | $350 – $750 | Start/Stop configuration |

| Multi-device (3–6 devices) | $650 – $1,800 | Push-buttons + pilot lights |

| Stainless steel station | $1,200 – $3,500 | High-corrosion applications |

| Custom large enclosures | $2,000 – $10,000+ | Panels, PLCs, multiple switches |

Not Sure Which Control Station Fits Your Budget?

Our specialists can help you compare enclosure materials, ratings and device configurations to match your exact application.

What Factors Affect the Price of Explosion-Proof Control Stations?

Several factors determine the final cost:

Number of devices (buttons, switches, lights)

Material type (aluminum vs stainless steel)

Hazardous location rating (C1D1 vs C1D2 vs ATEX/IECEx)

Weatherproofing needs

Brand and manufacturing origin

Custom engineering requirements

Simpler stations cost a few hundred dollars, while high-spec stainless units or custom panels may exceed $5,000.

Which Certifications Apply to Explosion-Proof Control Stations?

Understanding certification requirements ensures compliance and safety.

North America: NEC / CEC Certifications

Common North American ratings include:

Class I Division 1 (C1D1) – Flammable gases present during normal operations

Class I Division 2 (C1D2) – Flammable gases present only during abnormal conditions

Class II/III Divisions – Dusts and fibers

Control stations must also comply with:

UL 1203

UL 50E

NEMA 7/9 classifications

International: ATEX / IECEx Certifications

Explosion-proof stations used globally adhere to ATEX/IECEx rules:

Zone 1 – Frequent hazardous presence

Zone 2 – Occasional hazardous presence

Ex d (flameproof) certification for enclosures

Ex e, Ex ia, Ex ib where intrinsically safe circuits interface

Want to Understand Hazardous Location Ratings Better?

Explore our most trusted educational guides to master C1D1, ATEX zones and the difference between Explosion-Proof and Intrinsically Safe equipment.

What Are the Best Materials and Configurations for Different Industries?

Below is a comparison table showing industry-specific recommendations.

Comparison Table: Best Explosion-Proof Control Station Options by Industry

| Industry | Recommended Material | Device Configuration | Hazard Rating | Notes |

|---|---|---|---|---|

| Oil & Gas | Aluminum or Stainless Steel | Start/Stop + E-Stop + pilot lights | C1D1 / Zone 1 | Rugged, corrosion-resistant |

| Chemical Plants | Stainless Steel | Multi-device panels | C1D1 | Higher chemical resistance |

| Marine / Offshore | Stainless Steel | Selector + E-Stop | C1D1 | Superior saltwater resistance |

| Grain Handling | Cast Aluminum | Push-button + pilot light | C2D1 | Dust-rated |

| Pharmaceutical | GRP or Stainless | Status lights + selector switches | C1D2 | Cleanroom friendly |

| Food Manufacturing | Stainless Steel | E-Stop + washdown-safe switches | C1D2 | Hygienic surfaces |

“Best Choice For” Summary

Corrosive environments: Stainless steel

General industrial: Aluminum

Dust-intensive operations: Aluminum or cast iron

Marine and offshore: Stainless steel

Custom panels: Modular or multi-device housings

FAQs About Explosion-Proof Control Stations

Are explosion-proof and intrinsically safe the same?

No. Explosion-proof enclosures contain an ignition, while intrinsically safe circuits prevent ignition altogether. They are often used together but serve different functions.

Can I install explosion-proof control stations outdoors?

Yes. Most units are NEMA 4/4X or IP66 rated, meaning they can withstand harsh outdoor environments including rain, dust, and extreme temperatures.

What maintenance is required for explosion-proof control stations?

Routine inspection of flame paths, threads, gaskets, and seals is necessary. NEMA/IEC standards specify annual or semi-annual inspections depending on conditions.

Do explosion-proof stations require conduit or cable glands?

Yes. For compliance, only certified explosion-proof fittings, conduit seals, or Ex-rated cable glands should be used.

Can explosion-proof control stations be custom-built?

Absolutely. Many manufacturers build custom configurations including advanced control components, PLC interfaces, and multi-switch layouts.

Ready to Build a Safer Hazardous Location Control System?

Let our experts help you select the right control stations, junction boxes and enclosures for your site.

Conclusion: Choosing the Right Explosion-Proof Control Station

When selecting an explosion proof control station, you must consider enclosure material, hazardous location rating, internal control devices, and environmental conditions. Aluminum units offer cost-effective versatility, stainless steel excels in corrosive environments, and GRP provides lightweight, durable non-metallic protection. Switches, push-buttons, selector switches, and pilot lights can be customized to build a control system that supports safety, efficiency, and regulatory compliance.

Understanding pricing factors and common configurations ensures your investment aligns with operational needs, whether you’re managing a refinery, marine plant, grain facility, or processing operation.

If you need help understanding hazardous location equipment or intrinsically safe solutions, the Intrinsically Safe Store can support your research and application needs.