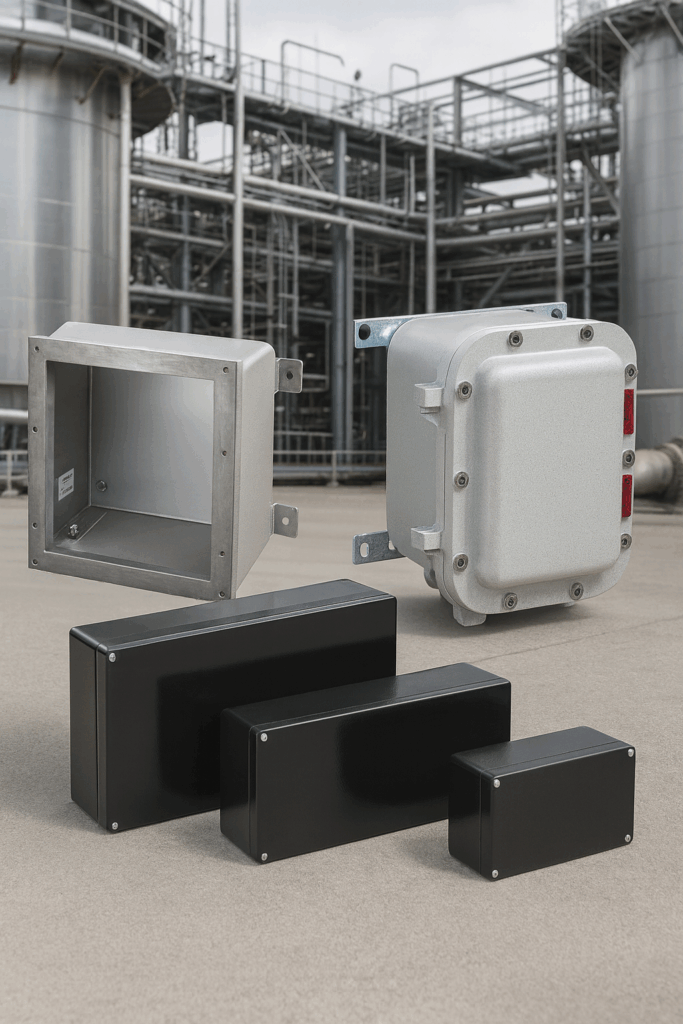

Explosion-proof enclosures are critical for protecting electrical components, instrumentation, communication equipment, and power systems in hazardous locations. These housings are engineered to contain internal explosions and prevent flame propagation into the surrounding atmosphere, making them indispensable in oil & gas, petrochemical, wastewater treatment, mining, grain handling, and any location classified as Class I Division 1, Class I Division 2, or ATEX/IECEx Zone 1 and Zone 2.

Understanding the explosion proof enclosure price, material options, certifications, sizing, and lead times is essential for choosing the correct solution for your installation. This guide covers all pricing categories, compares steel, aluminum, and polycarbonate enclosures, and includes a reference table of in-stock models available at Intrinsically Safe Store.

Need certified explosion-proof enclosures for your hazardous-area installation?

Browse Explosion-Proof EnclosuresWhat Is an Explosion-Proof Enclosure?

An explosion-proof enclosure is a certified housing designed to withstand an internal ignition of flammable gases or vapors and prevent it from escaping to the external hazardous atmosphere. These enclosures are constructed with flame paths, reinforced walls, threaded joints, certified cable entries, and materials capable of resisting high temperatures and mechanical stress.

Explosion-proof enclosures are used for:

Disconnect switches

Terminal and junction boxes

Control stations

Electrical panels

I/O and automation systems

Monitoring and communication equipment

Motor and pump controls

They must comply with standards such as UL 1203, NEC 500, ATEX, and IECEx depending on the region.

Explosion Proof Enclosure Price Breakdown

The explosion proof enclosure price varies widely depending on the enclosure size, certification, material, and features. Across current available models, prices typically fall into the following ranges:

Small Aluminum or Polycarbonate Enclosures

Compact housings used for junction boxes, small instruments, or low-voltage terminations. These models sit at the bottom of the price range and are ideal for confined-space installations or small I/O connections.

Medium Aluminum Explosion-Proof Enclosures

Common in industrial applications, these housings offer an excellent balance between cost, strength, and corrosion resistance. They are widely used for terminal boxes, automation systems, and general-purpose wiring interfaces.

Large Stainless Steel or Heavy-Duty Enclosures

These are significantly more expensive due to their reinforced construction and superior corrosion resistance. They are used in marine, chemical, offshore, and high-risk environments requiring maximum mechanical strength.

Flameproof Disconnect Enclosures

The most expensive category, used for isolating motors, pumps, and circuits in hazardous areas. Prices increase with amperage and physical size.

Factors That Influence Explosion-Proof Enclosure Price

Material Type

The enclosure material is one of the strongest cost drivers.

Steel

Maximum durability

Best for corrosive and high-temperature environments

Heaviest and most expensive material

Aluminum

Lightweight and corrosion resistant

More affordable than steel

Excellent heat dissipation

Polycarbonate / Composite

Lightweight

Resistant to corrosion and UV

Suitable for low-risk or control interfaces

Not suitable for flameproof Ex d applications

Size and Internal Volume

Larger enclosures require more raw material and more machining time, increasing total cost. The number of cover fasteners, hinge systems, and gasket requirements also scale with enclosure size.

Hazardous-Area Certification

C1D1 and ATEX Zone 1 explosion-proof housings require flameproof joints and thicker construction compared to C1D2 / Zone 2 increased-safety enclosures.

Want a deeper understanding of ATEX requirements before selecting your enclosure?

Read: What Is ATEX Certification?Additional Features

Hinged lids

Viewing windows

Disconnect switches

Multi-compartment layouts

Factory-installed terminals

Custom drilling and cable entry cutouts

These features significantly increase cost and lead time.

Explosion-Proof Enclosures (Overview Table)

Below is a reference table of explosion-proof and intrinsically safe enclosures currently available and in stock.

| Product | Material | Notes | Type |

|---|---|---|---|

| Kaixuan KX-EX09CBJ41-A Explosion Proof Enclosure | Aluminum | Compact enclosure for small devices | Explosion-proof |

| Intrinsically Safe Warom Increased Safety Enclosures BXT-e | Aluminum | Increased-safety design | IS enclosure |

| Intrinsically Safe Warom Explosion-Proof Enclosures BXT | Aluminum | Versatile hazardous-area enclosure | Explosion-proof |

| Explosion-proof Enclosures Warom BXT-□-W Series | Aluminum | Rugged build for harsh environments | Explosion-proof |

| Condor EX700 Explosion-Proof Enclosure | Aluminum | Cylindrical heavy-duty housing | Explosion-proof |

| Stainless Steel Explosion Proof Enclosure | Stainless Steel | Corrosion-resistant, robust design | Explosion-proof |

| Bartec ComEx 3-Gang Control Station | Composite | Multi-function control buttons | Intrinsically safe |

| Explosion Proof EXEP0804 Switch Disconnector | Steel | High-duty disconnect enclosure | Flameproof |

| Explosion Proof EXEP0404 Switch Disconnector | Steel | Compact disconnect | Flameproof |

| Explosion Proof EXEP0254 Switch Disconnector | Steel | Smallest disconnect model | Flameproof |

| Explosion Proof EXEP1804 Switch Disconnector | Steel | Large capacity disconnector | Flameproof |

| Warom Explosion-Proof Terminal Box | Aluminum | Junction/terminal housing | Explosion-proof |

| Stainless Steel Enclosure Mounting Kit | Stainless Steel | Wall and pole mounting | Accessory |

| Pepperl+Fuchs FB9221 Remote I/O Field Unit | Metal | ATEX/IECEx certified I/O system | Remote I/O |

Ready to choose the right explosion-proof enclosure for your project?

View In-Stock Explosion-Proof EnclosuresSteel vs. Aluminum vs. Polycarbonate Enclosures

Explosion-proof enclosures are built in different materials depending on the application.

Steel

Steel offers the highest strength and flameproof capability. It’s ideal for disconnect switches, control stations, and heavy-duty installations. Steel enclosures are heavier but unmatched in durability.

Aluminum

Aluminum is the most common material in explosion-proof enclosures. It’s lightweight, corrosion resistant, easy to machine, and significantly more affordable than steel. Aluminum enclosures strike a perfect balance for most applications.

Polycarbonate / Composite

These enclosures are lightweight and corrosion-resistant but not suitable for flameproof Ex d applications. They are ideal for intrinsically safe circuits, control interfaces, and low-voltage components.

Applications of Explosion-Proof Enclosures

Explosion-proof enclosures protect the following equipment types in hazardous zones:

Terminal and Junction Boxes

Used for cable splicing and termination in C1D1, C1D2, and Zone 1.

Disconnect Switch Enclosures

Provide motor or pump isolation in hazardous areas.

Control Stations

Allow safe user interface for start/stop functions, alarms, and emergency stops.

Instrumentation Housings

Used for transmitters, sensors, and control equipment in process industries.

Remote I/O Systems

House fieldbus and PLC interfaces in hazardous environments.

How to Choose the Right Explosion-Proof Enclosure

Selecting the correct enclosure involves balancing safety, budget, and installation requirements. Key considerations include:

Hazardous-area classification (C1D1, C1D2, Zone 1, Zone 2)

Material suitability for local environment

Required physical dimensions and internal volume

Cable entry requirements

Mounting method (wall, pole, pipe)

Thermal considerations

Required certifications (UL, ATEX, IECEx)

Lead time and stock availability

Lead Times for Explosion-Proof Enclosures

Lead times depend heavily on whether the enclosure is pre-manufactured or requires customization.

Fast-Ship, In-Stock Models

Standard aluminum and polycarbonate enclosures generally ship the fastest. Models such as Warom BXT, BXT-e, and compact aluminum enclosures typically have quick turnaround due to their modular designs.

Custom and Heavy-Duty Steel Enclosures

Steel disconnect enclosures, stainless steel housings, and enclosures requiring factory machining have longer lead times. Depending on configuration, these can range from several weeks to a few months, especially when cutouts, terminals, or disconnect switches must be installed at the factory.

FAQs

What is the typical explosion proof enclosure price?

Most enclosures range from low-cost compact housings to premium large flameproof enclosures. Prices vary according to size, certification, and material.

What material is best for hazardous areas?

Steel for maximum flameproof protection, aluminum for general use, and polycarbonate for low-risk control enclosures.

Can I modify an explosion-proof enclosure on site?

Modifications must be approved by the manufacturer; drilling or machining can void certification.

Do I need special cable glands?

Yes. Cable glands must match the enclosure’s certification level and hazardous-area rating.

Are all explosion-proof enclosures flameproof?

Explosion-proof typically refers to flameproof Ex d enclosures, but some models meet increased safety Ex e requirements. Verify the protection type before purchase.

Not sure which explosion-proof enclosure fits your hazardous-area requirements?

Request a Quote for Explosion-Proof EnclosuresConclusion

Understanding the explosion proof enclosure price, materials, features, and lead times ensures that your installation meets hazardous-area safety requirements while staying within budget. Aluminum enclosures provide excellent all-around performance, steel offers maximum strength for the harshest environments, and polycarbonate gives a cost-effective option for lower-risk applications.

With a wide selection of in-stock models—including disconnect switch enclosures, terminal boxes, and stainless steel housings—Intrinsically Safe Store provides solutions for every hazardous-area requirement.