Industrial environments that contain combustible gases, vapors, or dusts rely heavily on properly engineered ventilation systems. One of the most essential components of this system is the explosion proof exhaust fan, built to safely move air while preventing the ignition of hazardous atmospheres. From oil refineries to chemical storage rooms and paint booths, these fans help facilities meet strict safety standards while maintaining compliance with ATEX, IECEx, NEC, and NFPA regulations.

This guide explains everything you need to know about explosion-proof exhaust fans: airflow sizing, hazardous location certifications, Ex ratings, fan materials, installation considerations, and how to select the right model for your environment. Whether you’re an engineer, safety manager, or procurement leader, this article equips you with the knowledge to make a confident, compliant decision.

Shop Certified Explosion-Proof Exhaust Fans

Explore compliant exhaust solutions for hazardous areas and request pricing with confidence.

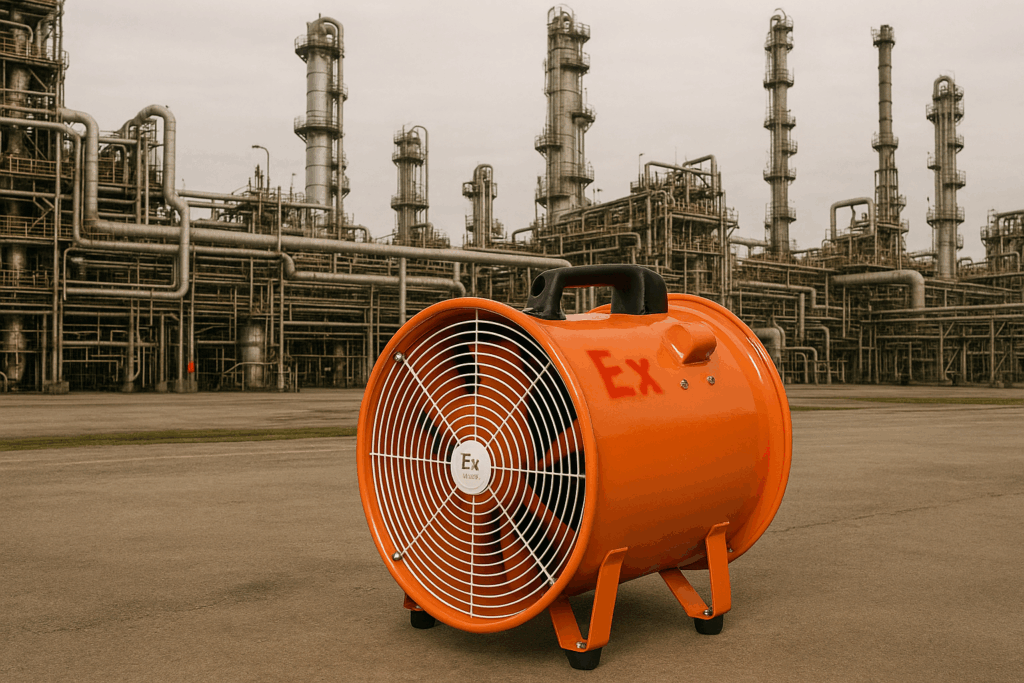

What Is an Explosion-Proof Exhaust Fan?

An explosion-proof exhaust fan is a mechanical ventilation device designed so that any internal sparks, heat, or electrical faults cannot ignite flammable substances in the surrounding environment. These fans use sealed housings, non-sparking materials, flameproof motors, and heavy-duty wiring to contain ignition sources while continuously removing hazardous air.

Explosion-proof fans are required in industries such as:

Oil & gas

Chemical manufacturing

Grain handling and milling

Battery charging rooms

Paint and coatings

Pharmaceuticals

Wastewater treatment

Explosion-proof does not mean the fan can withstand an external explosion. Instead, it means the fan will not contribute to one.

How Does an Explosion-Proof Exhaust Fan Work?

An explosion-proof exhaust fan reduces combustible concentrations by pulling contaminated air out of a room and replacing it with clean air from a safer source. The key difference from standard fans is the flameproof design, which prevents internal ignition sources from interacting with the ambient atmosphere.

Key engineering features include:

Sealed or flameproof motor housings

Non-sparking fan blades (aluminum, copper, composite)

Heavy-gauge, corrosion-resistant housings

Shaft seals to prevent fume ingress

Bonding and grounding paths

These features ensure the fan is safe for use in areas where gases, vapors, or dusts may be present at hazardous levels.

Certifications & Ratings for Explosion-Proof Exhaust Fans

What Certifications Should an Explosion-Proof Exhaust Fan Have?

The correct certification ensures the fan complies with hazardous location requirements in your region. The major systems include:

ATEX Certification (European Union)

ATEX applies to equipment used in explosive atmospheres under Directive 2014/34/EU.

Equipment groups:

Group I: Mining

Group II: Surface industries

Equipment categories correspond to area type:

Zone 0 / 1 / 2 for gases

Zone 20 / 21 / 22 for dusts

An ATEX-rated fan will carry markings like:

II 2G Ex d IIB T4 Gb

IECEx Certification (International)

IECEx is a globally recognized system ensuring consistent safety standards. It offers equivalent protection to ATEX but is easier to apply internationally since it uses a unified testing scheme.

IECEx markings resemble ATEX, including:

Explosion protection method (Ex d, Ex e, etc.)

Gas or dust group

Temperature class

Equipment protection level

North American NEC/CEC Hazardous Location Ratings

The NEC and CEC classify hazardous environments using:

Class I – Gases and vapors

Class II – Dusts

Class III – Fibers

And:

Division 1 – Hazard present continuously or frequently

Division 2 – Hazard present occasionally

Example:

Class I, Division 1, Groups C & D

Explosion-proof exhaust fans must match the exact class/division or class/zone of the installation site.

Confirm Your Rating, Then Choose the Right Fan

Share your zone/class and room details—our team can help you validate compliance and airflow sizing.

What Do Ex Ratings Mean on an Explosion-Proof Exhaust Fan?

Each Ex marking describes how the fan prevents ignition. Common designations include:

| Ex Code | Meaning |

|---|---|

| Ex d | Flameproof enclosure |

| Ex e | Increased safety |

| Ex nA | Non-sparking construction |

| Ex tD | Protection for dust atmospheres |

| T1–T6 | Maximum surface temperature rating |

T-ratings indicate the maximum temperature any external component can reach.

Example: T4 → max 135°C surface temperature

A fan installed in a low-temperature ignition environment must match or exceed the required T-rating.

Airflow Requirements: How Much CFM Do You Need?

How Do You Calculate the Required Airflow for a Hazardous Location?

Airflow for an explosion-proof exhaust fan is measured in CFM (cubic feet per minute). To calculate CFM, start with the room’s volume and required air changes per hour (ACH).

CFM = (Room Volume × ACH) ÷ 60

Example

Room size: 30 ft × 20 ft × 10 ft

Room volume: 6,000 ft³

Recommended ACH for a solvent mixing room: 20 ACH

CFM = (6,000 × 20) ÷ 60 = 2,000 CFM

What ACH Values Are Recommended for Hazardous Areas?

| Area Type | Recommended ACH |

|---|---|

| Solvent mixing rooms | 20–30 ACH |

| Paint booths | 50–100 ACH |

| Chemical storage | 10–20 ACH |

| Battery charging rooms | 6–10 ACH |

| Powder processing | 12–20 ACH |

| Pharmaceutical manufacturing | 15–25 ACH |

These values are sourced from industry ventilation standards and should be validated by your safety engineer.

Selection Criteria: What to Look for When Choosing an Explosion-Proof Exhaust Fan

What Features Matter Most When Selecting an Explosion-Proof Exhaust Fan?

Choosing the right fan requires evaluating both the hazardous environment and the mechanical performance of the fan. Key considerations include:

Correct hazardous location certification (ATEX/IECEx/NEC)

Airflow capacity (CFM) and static pressure

Motor type (explosion-proof, TEFC, flameproof)

Fan material (stainless steel, aluminum, spark-resistant composite)

Corrosion resistance

Ingress Protection (IP rating)

Mounting orientation (wall, roof, inline)

Energy efficiency and speed control capability

Whenever possible, select fans with permanently lubricated bearings and sealed housings to reduce maintenance intervals.

How Do Materials Affect Safety and Performance?

Materials must withstand corrosive chemicals, moisture, or dust.

| Material | Advantages | Best For |

|---|---|---|

| Stainless Steel | Highly corrosion-resistant | Marine, chemical, wastewater |

| Aluminum | Lightweight, non-sparking | General industrial, indoor ATEX zones |

| Composite/FRP | Corrosion-proof, spark-free | Battery rooms, chlorine rooms |

| Powder-Coated Steel | Economical | Low-corrosion environments |

Material compatibility is critical when handling acids, solvents, or abrasive dusts.

Installation Considerations

How Do Installation Conditions Affect an Explosion-Proof Exhaust Fan?

Even the best fan will not perform correctly if poorly installed. Key factors include:

Duct length and number of elbows – Reduce static pressure loss

Fan placement relative to fume source – Reduces buildup

Ambient temperature – Must match motor rating

Structural support – Prevents vibration and misalignment

Grounding and bonding – Required by NEC and ATEX

Access for maintenance – Ensures compliance inspections

Roof penetrations, wall openings, and duct transitions must be sealed to maintain hazardous area boundaries.

Types of Explosion-Proof Exhaust Fans

Wall-Mounted Explosion-Proof Fans

Simple installation, best for smaller rooms and direct-to-outside airflow.

Roof-Mounted Explosion-Proof Fans

Ideal for high-volume airflow or vertical discharge requirements.

Inline Explosion-Proof Duct Fans

For long duct runs or applications needing isolated motor placement.

Comparison Table: Explosion-Proof Exhaust Fan Types

| Feature | Wall-Mount EX Fan | Roof-Mount EX Fan | Inline EX Duct Fan |

|---|---|---|---|

| Airflow Capacity | Medium | High | Medium–High |

| Certifications | ATEX/IECEx/NEC | ATEX/IECEx/NEC | ATEX/IECEx |

| Installation Difficulty | Low | Moderate | High |

| Maintenance Access | Easy | Requires roof access | Motor may be remote |

| Best For | Battery rooms, mixing rooms | Paint booths, large facilities | Pharmaceutical, chemical ducts |

Best By Industry

Oil & Gas: Inline or wall-mount

Chemical Processing: Roof-mounted high-volume units

Battery Rooms: Wall-mounted composite systems

Grain Handling: Heavy-duty dust-rated fans

Paint Booths: High-capacity roof exhaust

Complete Your Hazardous Ventilation Setup

Pair certified airflow with the right motor and portable detection for stronger risk control.

Frequently Asked Questions (FAQs)

What is the difference between intrinsically safe and explosion-proof?

Explosion-proof equipment contains ignition sources within flameproof housings, while intrinsically safe equipment limits electrical energy so ignition cannot occur. Fans must be explosion-proof, not intrinsically safe.

Can I use a standard fan in a hazardous location?

No. Standard fans can create sparks, static discharge, or hot surfaces, all of which can ignite flammable atmospheres. Only certified explosion-proof models are compliant.

How often should explosion-proof fans be inspected?

Most industrial sites inspect visually every 90 days and perform detailed checks annually, including bearing lubrication, seal condition, and electrical continuity.

Are explosion-proof fans louder?

They often are, due to heavy-duty motors and enclosures. However, modern EX fans increasingly incorporate noise-reduction designs.

Do explosion-proof fans replace gas detectors?

No. Ventilation complements detection systems but does not eliminate the need for monitoring.

Conclusion: How to Choose the Right Explosion-Proof Exhaust Fan

Selecting the correct explosion proof exhaust fan requires understanding your hazardous area classification, airflow needs, environmental conditions, and installation requirements. By matching certifications to your zone or class/division, calculating correct CFM, choosing corrosion-resistant materials, and planning proper installation, you create a safer, compliant, and more efficient facility.

For certified devices used in hazardous environments—including communication tools, cameras, detectors, and more—explore the Intrinsically Safe Store.