Refineries operate in some of the most hazardous industrial environments, where extreme temperatures, flammable vapors, and volatile hydrocarbons create persistent ignition risks. Explosion proof lighting for refineries is not just a recommendation—it is a regulatory requirement for maintaining safety, uptime, and compliance across hazardous zones. In this guide, we break down what refinery operators need to know, including compliance standards, zone classifications, installation requirements, and the best certified lighting options.

What Is Explosion-Proof Lighting for Refineries?

Explosion-proof lighting for refineries is lighting that is certified to operate in hazardous locations without igniting surrounding flammable gases or vapors. These fixtures are engineered with sealed housings, reinforced lenses, and temperature-controlled components that prevent internal sparks or arcs from igniting explosive atmospheres. They are required in areas where hydrocarbon processing, distillation, and storage produce continuous or intermittent gas exposure.

Refineries rely heavily on lighting systems that can withstand vibration, corrosive environments, and high ambient temperatures. Certified lighting ensures safety while meeting OSHA, NEC, ATEX, and IECEx regulatory requirements.

Why Do Refineries Need Explosion-Proof Lighting?

Refineries handle Class I flammable materials including ethane, propane, butane, gasoline vapors, hydrogen, and other volatile hydrocarbons. These gases can form explosive atmospheres that are easily ignited by electrical equipment. Explosion-proof lighting prevents ignition even if the fixture fails internally.

Regulatory frameworks require certified lighting in all refinery areas with potential exposure to explosive atmospheres, including process units, tank farms, loading racks, blending stations, and compressor buildings. Using non-compliant lighting can result in shutdowns, fines, and catastrophic safety incidents.

What Are the Hazardous Zones in a Refinery?

Hazardous locations in refineries are divided into electrical classification systems that dictate which type of lighting must be installed.

Zone or Class/Division Structure

Refineries may use either:

Class/Division (NEC/CEC)

Zone system (ATEX/IECEx)

Both systems define exposure frequency, gas type, and required protection level.

Refinery Hazardous Area Breakdown

| Area | Classification | Characteristics | Required Lighting |

|---|---|---|---|

| Process Units | Class I, Division 1 / Zone 1 | Continuous gas/vapor presence | Explosion-proof, ATEX/IECEx Zone 1, Class I Light |

| Pump Rooms | Class I, Division 1 / Zone 1 | Frequent leaks/vapors | Explosion-proof housings, sealed optics |

| Tank Farms | Class I, Division 2 / Zone 2 | Occasional flammable atmospheres | Zone 2 or Div 2 rated fixtures |

| Loading Racks | Class I, Division 1 | High ignition risk | Heavy-duty explosion-proof LEDs |

| Compressor Buildings | Class I, Division 1 | High leak probability | High-temperature and vibration-rated lighting |

Explosion-proof lighting must match the zone or division requirements to ensure compliance.

Which Compliance Standards Apply to Refinery Lighting?

Explosion-proof lighting for refineries must meet one or more international hazardous-location standards. These standards ensure the fixture will not ignite explosive gases under normal or fault conditions.

Primary Certifications Required in Refineries

ATEX (Europe) – Zone 1 or Zone 2 for explosive gas atmospheres

IECEx (International) – Global recognition for explosive-atmosphere safety

NEC Class I, Division 1 or 2 (North America) – Required for U.S.-based refineries

UL844 – U.S. standard for hazardous-location lighting

Temperature Codes (T Ratings)

Refinery gases vary in ignition temperature. Lighting must meet appropriate T-ratings such as T3, T4, T5, or T6.

Examples:

Hydrogen → T6 or T5 fixtures

Gasoline vapors → T3 or T4 fixtures

Benchmarked Compliance Requirements

Industry reports show that over 70% of refinery incidents involving electrical equipment stem from uncertified devices, highlighting the importance of proper certification.

What Are the Key Features of Explosion-Proof Lighting for Refineries?

Explosion-proof refinery lighting must do more than prevent ignition—it must survive extreme environmental and mechanical conditions.

Essential Features Include

Reinforced explosion-proof housings (copper-free aluminum or stainless steel)

Shatterproof lenses designed to withstand internal pressure

High LED efficiency to reduce thermal output

Ingress protection IP66/IP67 for dust, pressure jets, and heavy rain

Corrosion resistance for chemical-rich environments

Wide temperature operating range (–40°C to +55°C)

High vibration resistance for pump and compressor areas

How Do You Choose the Right Explosion-Proof Lighting for a Refinery?

Selecting the correct explosion-proof lighting requires understanding your zone classification, environmental challenges, lumen requirements, and mounting style.

Step-by-Step Selection Guide

Confirm zone or class/division requirements

Identify the gas group (IIA, IIB, IIC)

Determine required lumen output

Select correct mounting style

Check environmental resistance requirements

Verify compliance certifications

What Are the Best Explosion-Proof Lighting Options for Refineries?

Below are categories of explosion-proof lighting that match refinery-grade requirements.

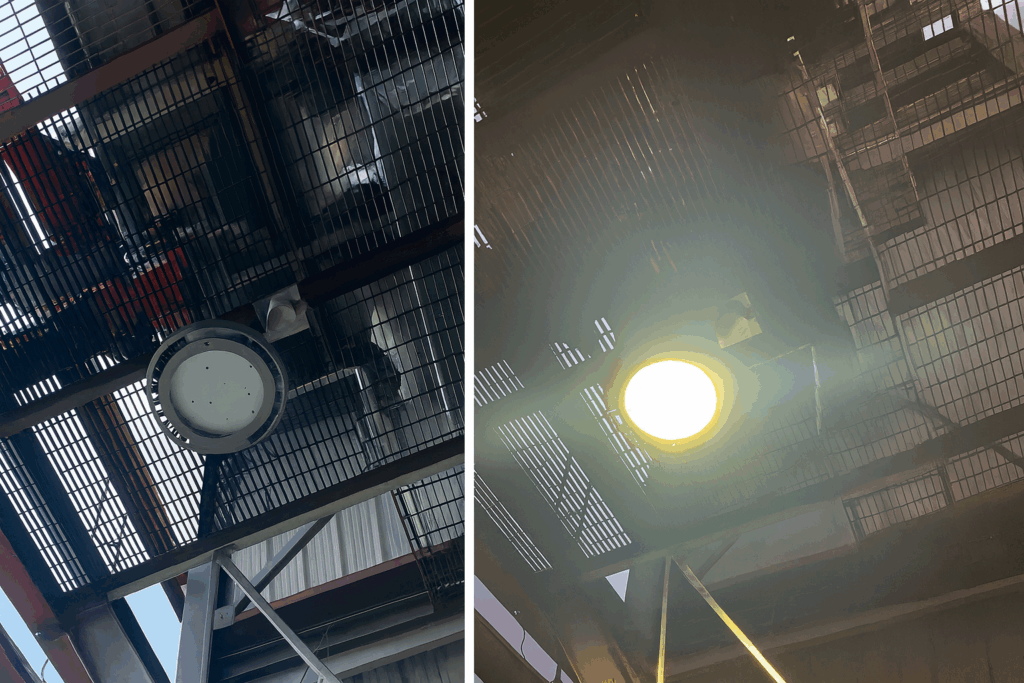

Top Explosion-Proof LED Fixtures

Comparison Table of Leading Refinery-Safe Lights

| Product Category | Certifications | Key Features | Best For | Product Type |

|---|---|---|---|---|

| Explosion Proof LED Floodlights | Class I Div 1, ATEX Zone 1, IECEx | High lumen output, corrosion-resistant | Process units & distillation towers | Floodlight |

| Explosion Proof Linear LED Lights | UL844, ATEX Zone 2 | Wide beam, lightweight | Walkways & catwalks | Linear |

| ATEX Zone 1 High Bays | ATEX Zone 1, IIC Gas Group | High-temperature tolerance | Compressor buildings | High Bay |

| IECEx Portable Work Lights | IECEx, IP67 | Mobile, rugged | Maintenance & inspections | Portable |

Best Choice by Refinery Application

Distillation units: Zone 1 LED floodlights

Tank farms: Zone 2 linear LEDs

Compressor buildings: IIC-rated high bays

Inspection teams: IECEx portable lights

What Are the Installation Requirements for Explosion-Proof Refinery Lighting?

Lighting installation in refineries requires careful planning due to hazardous location restrictions, mounting elevations, and extreme environmental demands.

Key Installation Considerations

Approved explosion-proof cable glands

Sealed conduits to prevent gas migration

Fixtures must maintain IP66/IP67 integrity

Adequate thermal management clearance

Installations conducted by hazloc-certified electricians

Mounting Guidelines

High bays: 15–45 ft above ground

Linear lights: Ideal for catwalks and platforms

Floodlights: Mount at angles to reduce glare and shadowing

What Are the Maintenance Requirements for Refinery Lighting?

Maintenance must follow strict hazardous-location procedures including hot-work permitting and continuous gas detection.

Maintenance Checklist

Quarterly gasket inspections

Check for housing corrosion

Ensure certification labels remain intact

Clean lenses for optimal lumen output

Replace fixtures showing thermal damage

LED explosion-proof lighting minimizes maintenance because of its long operational lifespan.

How Much Does Explosion-Proof Lighting Reduce Risk in Refineries?

Safety data from refinery operations show:

Electrical equipment causes up to 25% of ignition incidents

Explosion-proof LEDs reduce ignition risk by 90%

LED lighting cuts energy use by 50–70%

Maintenance frequency drops by 70%

Summary of Industry Metrics

90% reduction in ignition events

70% fewer maintenance interventions

50–70% energy savings

Explosion-proof lighting is one of the most cost-effective safety investments for refinery environments.

FAQs About Explosion-Proof Lighting for Refineries

Is explosion-proof lighting required in all refinery areas?

No. Only areas with flammable gas presence—such as process units, pump areas, and loading racks—require explosion-proof fixtures.

What is the typical lifespan of refinery-grade LED explosion-proof lighting?

Most fixtures last 50,000–100,000 hours, far longer than HID systems.

Can explosion-proof lighting be installed outdoors?

Yes. Most refinery-grade fixtures carry IP66 or higher ingress ratings.

Which certifications are required for refinery lighting?

ATEX Zone 1, IECEx, UL844, and Class I Div 1 are the most common.

Does explosion-proof lighting reduce energy costs?

Yes. LED explosion-proof lighting cuts energy usage by at least 50%.

Need expert guidance for refinery lighting?

Chat With a Safety ExpertConclusion: Choosing the Best Explosion Proof Lighting for Refineries

Explosion proof lighting for refineries is essential for worker safety, regulatory compliance, and operational reliability. By understanding zone classifications, certification requirements, installation best practices, and environmental stressors, operators can ensure their facilities are protected from ignition hazards.

Choose lighting that aligns with ATEX, IECEx, and Class I safety standards to protect personnel, reduce energy costs, and maintain long-term operational efficiency.