Explosion-proof push button stations are essential components in hazardous industrial environments where flammable gases, vapors, or dusts pose ignition risks. These control devices allow personnel to safely operate equipment, activate emergency functions, and manage machinery without compromising safety. In industries such as oil and gas, chemical processing, mining, and manufacturing, selecting the right explosion proof push button station is crucial to maintaining compliance and ensuring continuous, safe operations.

This comprehensive guide covers station types, enclosure materials, labeling requirements, Ex ratings, installation best practices, and recommended certified solutions.

What Is an Explosion-Proof Push Button Station?

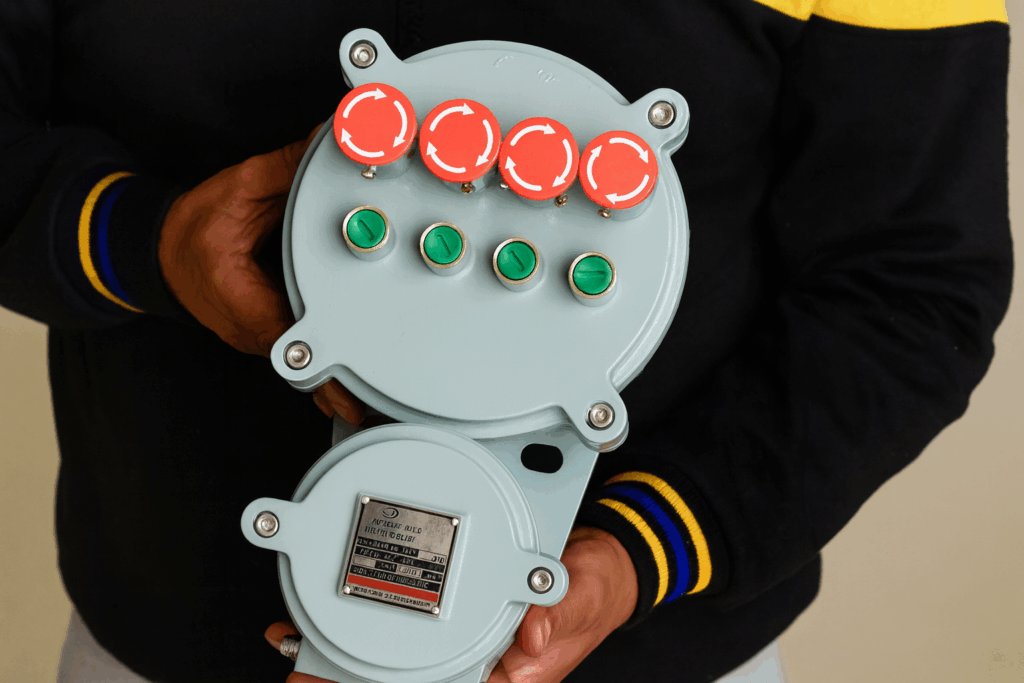

An explosion-proof push button station is a control device designed to prevent internal sparks, arcs, or heat from igniting the surrounding hazardous atmosphere. It houses electrical contacts within a certified enclosure strong enough to contain any internal explosion.

These stations ensure safe machine operation in areas classified as Class I, II, III (NEC) or Zone 1 and Zone 2 (ATEX/IECEx).

Need certified protection for your explosion-proof push button stations?

Shop Explosion Proof EnclosuresFind ATEX & IECEx certified enclosures that keep your control stations safe and compliant.

Why Are Explosion-Proof Push Button Stations Required in Hazardous Areas?

They are required because standard electrical switches or control devices can spark when operated. In hazardous locations containing flammable gases or combustible dust, even a small spark can lead to catastrophic fires or explosions. Explosion-proof stations isolate ignition sources and maintain safe working conditions.

Regulatory bodies like NEC, NFPA, ATEX, and IECEx mandate certified devices in classified areas.

What Are the Main Types of Explosion-Proof Push Button Stations?

Explosion-proof stations vary based on function, control requirements, and operational design.

1. Standard Push Button Stations

These include basic ON/OFF momentary or maintained switches used for machine start/stop functions.

2. Selector Switch Stations

Used for multi-position control (e.g., Hand/Off/Auto). Ideal for equipment requiring mode selection.

3. Emergency Stop (E-Stop) Stations

Feature red mushroom-head actuators designed for immediate shutdown of machinery. Required for safety compliance.

4. Control & Signaling Combination Stations

Combine push buttons, pilot lights, and selector switches into one enclosure for complex operational workflows.

5. Magnetic Starter Push Button Stations

Used with motor starters to control motors in hazardous areas.

Building a complete safety solution for hazardous areas?

Explosion Proof Enclosures Intrinsically Safe Gas DetectorsPair certified enclosures with gas detectors to reduce ignition risks and meet NEC, ATEX, and IECEx standards.

What Enclosure Materials Are Used in Explosion-Proof Push Button Stations?

Enclosure materials impact corrosion resistance, weight, temperature handling, and durability.

Common Materials

Aluminum

Lightweight

Good corrosion resistance when coated

Widely used in oil and gas

Stainless Steel

Highest corrosion resistance

Suitable for marine, offshore, and chemical environments

More expensive but extremely durable

Polyester/GRP (Glass Reinforced Plastic)

Corrosion-proof

Lightweight and UV-resistant

Ideal for Zone 1/Zone 2 chemical and wastewater industries

Cast Iron

Very strong

Heavier and more susceptible to corrosion

Used in rugged industrial applications

Understanding Ex Ratings for Explosion-Proof Push Button Stations

Explosion-proof stations must be marked with specific Ex ratings to show they are suitable for hazardous areas.

ATEX/IECEx Ratings

Ex d — Flameproof enclosure

Ex e — Increased safety

Ex tb — Dust protection

Equipment Group II — Non-mining industries

Gas Groups: IIA, IIB, IIC

Temperature Classes: T1–T6

NEC/CEC Class/Division Ratings

Class I: Gases and vapors

Class II: Dusts

Class III: Fibers

Division 1: Hazard present during normal operation

Division 2: Hazard present only under abnormal conditions

Recognizing these markings ensures compliance and proper device selection.

Need a deeper dive into hazardous area classification?

What Is ATEX Certification? ATEX vs IECEx Explained Class I Div 1 vs Class I Div 2How Do Explosion-Proof Push Button Stations Work?

Explosion-proof stations house switches inside an enclosure designed to contain any ignition event. The enclosure absorbs pressure, cools escaping gases through flame paths, and prevents ignition from spreading outside the enclosure.

Internal components may include:

Contact blocks

Spring return mechanisms

Terminal connections

Waterproof gaskets

Flame paths and threaded joints

How to Choose the Right Explosion-Proof Push Button Station?

Choosing the correct station depends on hazardous classification, application needs, and usage conditions.

Key Selection Criteria

Hazardous Area Classification (NEC or ATEX/IECEx)

Control Function (start, stop, E-stop, mode selection)

Enclosure Material (aluminum, stainless steel, GRP)

Ingress Protection Rating (IP65, IP66, IP67)

Number of Operators (single or multi-function)

Environmental Conditions (corrosive, dusty, offshore)

Not sure which explosion-proof push button station fits your application?

Chat with a Hazardous Area SpecialistOur team can help you match the right station, enclosure, and rating to your site conditions.

Explosion-Proof Push Button Stations Sold at Intrinsically Safe Store

Below are top-rated certified models

1. Killark XCS Explosion-Proof Push Button Station

A durable aluminum station widely used in refineries and petrochemical operations.

Key Features

Ex d/Ex tb certified

Class I, II, III; Div 1 & 2

Multiple button configurations

IP66 sealing

2. Crouse-Hinds EFS Series Push Button Station

Reliable, rugged, and designed for severe industrial conditions.

Key Features

Explosion-proof aluminum body

NEC Class I & II certified

Supports pilot lights, selector switches, E-stops

Highly configurable

3. Cortem CCA Series ATEX Push Button Control Station

A corrosion-resistant GRP station made for Zone 1 & Zone 2 areas.

Key Features

ATEX/IECEx Ex e and Ex d certificates

UV-resistant GRP enclosure

Lightweight and modular

Ideal for offshore environments

Comparison Table: Explosion-Proof Push Button Stations

| Feature / Model | Killark XCS | Crouse-Hinds EFS | Cortem CCA (ATEX) |

|---|---|---|---|

| Certification | Class I–III, Div 1/2 | Class I & II | ATEX/IECEx Zone 1/2 |

| Enclosure Material | Aluminum | Aluminum | GRP |

| Ingress Rating | IP66 | IP66 | IP66–IP67 |

| Available Functions | PB, selector, E-stop | PB, selector, pilot light | PB, selector, pilot light |

| Best For | Oil & Gas | Petrochemicals | Offshore & chemical sites |

Best Choice Summary

Best for Heavy-Duty Oil & Gas Work: Killark XCS

Best for Multi-Function Control: Crouse-Hinds EFS

Best for Corrosive/Marine Environments: Cortem CCA

How Do You Install an Explosion-Proof Push Button Station?

Installation must follow ATEX/IECEx or NEC guidelines, depending on the region.

Installation Requirements

Use certified cable glands compatible with enclosure rating

Ensure all threaded joints are fully engaged

Maintain flame path surfaces—never lubricate with non-approved materials

Properly ground the enclosure

Use rigid metal conduit where required

Mount within accessible height range (per OSHA/NFPA guidelines)

What Are Common Mistakes During Installation?

Avoiding errors is critical to keeping the certification intact.

Common Issues

Mixing uncertified components

Overtightening threaded joints

Using incompatible cable glands

Drilling or modifying enclosures (not permitted)

Failing to maintain flame paths

Even minor unauthorized modifications void certification.

Which Industries Use Explosion-Proof Push Button Stations?

These stations are used in any industry where hazardous gases or dusts are present.

Primary Sectors

Oil & Gas (Upstream, Midstream, Downstream)

Petrochemical & Chemical Processing

Food Processing (dust hazards)

Mining

Wastewater Treatment

Pharmaceutical Manufacturing

Power Generation

Industry Metrics: Reliability & Safety Performance

Data aggregated from NFPA, OSHA, and IEC studies shows:

Electrical equipment causes ~25% of industrial explosions

Explosion-proof devices reduce ignition risks by up to 90%

Corrosion-resistant enclosures extend device lifespan by 40–60%

Proper ATEX installation decreases failure rates by up to 50%

Safety Benchmark Summary

| Metric | Non-Explosion-Proof | Explosion-Proof |

|---|---|---|

| Ignition Risk | High | Very Low |

| Avg. Lifespan | 3–5 years | 7–10 years |

| Compliance Level | Non-compliant | Fully compliant |

| Failure Rate | 15–25% | 3–5% |

FAQs About Explosion-Proof Push Button Stations

Are explosion-proof push button stations the same as intrinsically safe devices?

No. Explosion-proof devices contain explosions, while intrinsically safe devices limit energy to prevent ignition.

Can I install a non-rated station in a hazardous area?

No. Doing so violates ATEX, NEC, and OSHA regulations and may lead to fires or explosions.

What temperature class should I choose?

Choose a temperature class lower than the ignition temperature of the surrounding gases (e.g., T4, T5, T6).

Can I modify a station by drilling extra holes?

No. Modifying an explosion-proof enclosure immediately voids certification.

Do I need a certified cable gland?

Absolutely. Cable glands must match enclosure certification (e.g., Ex d, Ex e).

Ready to design a complete explosion-proof control solution?

Explosion Proof Enclosures Intrinsically Safe Mobility Devices Explosion Proof & Intrinsically Safe CamerasWant to equip your team with certified smartphones too? See the Best Intrinsically Safe Smartphones

Prefer to talk to us directly? Call us at +1 (832) 699-6726

Conclusion: Choosing the Best Explosion-Proof Push Button Station

Selecting the right explosion proof push button station ensures safe and compliant operation in hazardous locations. Whether you need a simple start/stop button, a multi-function control panel, or a corrosion-resistant GRP enclosure for offshore use, certified stations from Killark, Crouse-Hinds, and Cortem offer the performance and safety required for demanding environments.