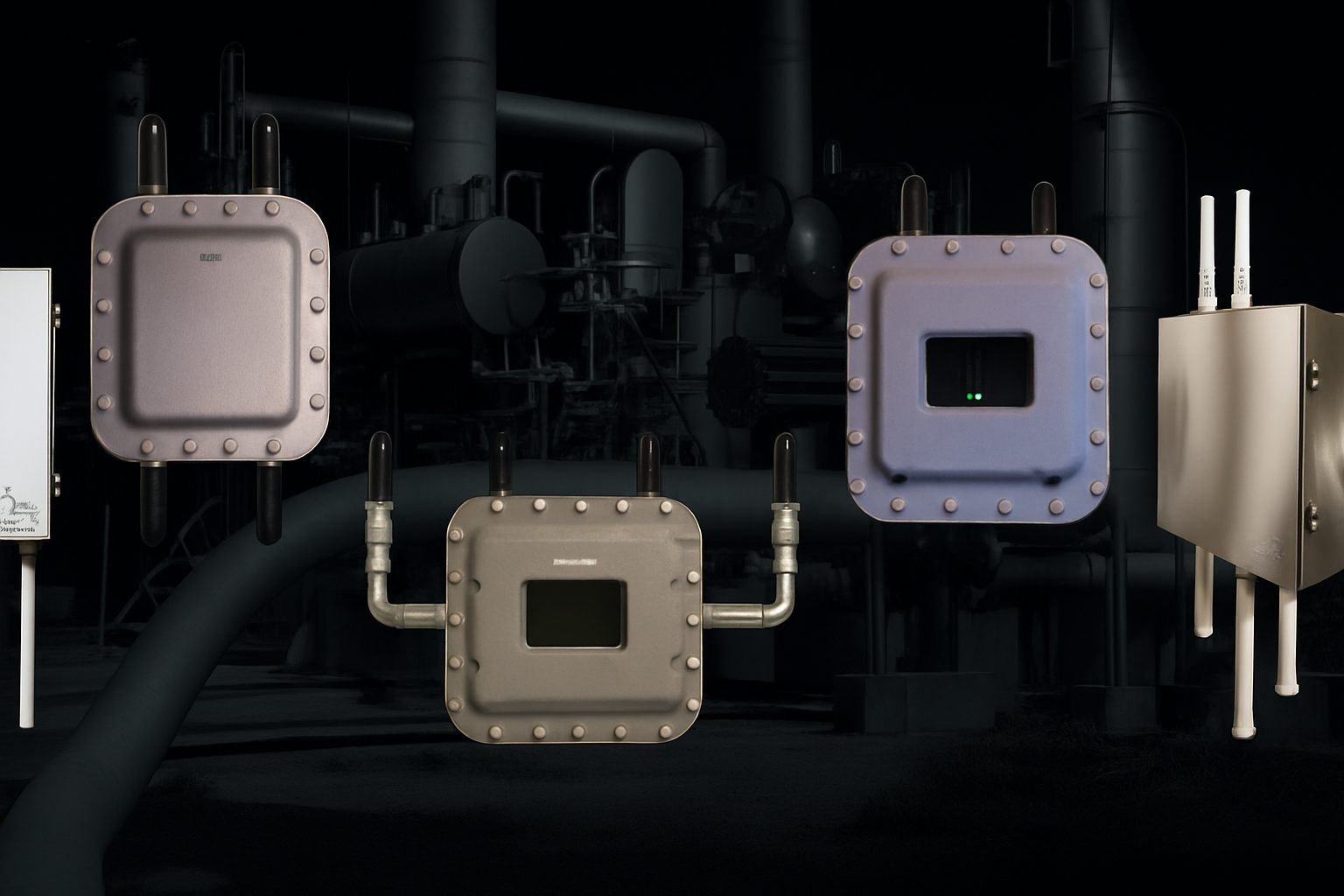

Hazardous locations present some of the most demanding challenges for electrical equipment. Industrial sites dealing with flammable gases, vapors, dust, or fibers require protective housings that keep ignition sources fully contained while ensuring equipment reliability. Hazardous area electrical enclosures are central to this protection strategy, serving as the first line of defense between electrical components and explosive atmospheres.

This guide provides a complete breakdown of enclosure types, materials, certifications, temperature considerations, and installation insights to help engineers, designers, and safety professionals select enclosures that meet both operational and regulatory demands.

What Are Hazardous Area Electrical Enclosures?

Hazardous area electrical enclosures are specially designed housings that contain electrical components and prevent them from igniting flammable atmospheres. These enclosures restrict the release of heat, arcs, or sparks that could occur under normal operation or during electrical faults.

They are commonly used in industries such as oil and gas, chemical processing, mining, food production, grain handling, wastewater treatment, and pharmaceuticals—anywhere explosive gases or dusts may be present.

Why They Matter

Prevent ignition of hazardous atmospheres

Protect sensitive equipment from exposure to corrosive or dusty environments

Ensure compliance with ATEX, IECEx, UL, CSA, and NEC requirements

Improve system reliability and reduce maintenance

How Are Hazardous Areas Classified?

Before selecting an enclosure, it’s critical to understand the hazard classification system.

Hazardous Area Classifications

ATEX / IECEx (Zone System)

Zone 0 – Continuous presence of explosive gas

Zone 1 – Likely presence of explosive gas

Zone 2 – Unlikely or infrequent gas presence

Zone 20/21/22 – Combustible dust environments

North American (Class/Division System)

Class I – Gases and vapors

Class II – Combustible dust

Class III – Fibers and flyings

Division 1 – Likely presence of hazard

Division 2 – Unlikely or infrequent presence

Electrical enclosures must match the classification—and failure to do so can result in catastrophic incidents or legal violations.

What Types of Hazardous Area Electrical Enclosures Exist?

Hazardous area electrical enclosures fall into several key protection concepts. Each is intended for different hazardous zone conditions and equipment types.

Flameproof / Explosion-Proof Enclosures (Ex d)

These enclosures are engineered to contain an internal explosion without allowing it to escape into the external atmosphere.

Key Characteristics

Heavy-duty aluminum, stainless steel, or cast iron

Flame paths dissipate ignition energy

Suitable for Zone 1/Class I Div 1

Common for motors, starters, transformers, and high-energy devices

Intrinsically Safe Enclosures (Ex i)

Used for low-energy equipment, intrinsically safe enclosures ensure electrical energy is kept below ignition thresholds.

Key Characteristics

Lightweight materials

Often used with IS barriers or isolators

Suitable for Zone 0/1 and instrumentation-level devices

Increased Safety Enclosures (Ex e)

Designed to prevent arcs, sparks, or hot surfaces under normal operation.

Key Characteristics

Reinforced terminals and insulation

No internal ignition sources allowed

Suitable for Zone 1

Used for junction boxes, terminal enclosures, and lighting fixtures

Pressurized Enclosures (Ex p)

Maintain a protective gas (air or inert) under pressure to isolate internal components from the atmosphere.

Key Characteristics

Ideal for sensitive electronics, PLCs, VFDs

Suitable for Zone 1/2

Requires purge control system

Dust-Ignition Protection Enclosures (Ex t)

Designed specifically to exclude dust and limit temperature.

Key Characteristics

IP6X sealing

Certified for Zone 21/22

Used heavily in grain, food, milling, and pharmaceuticals

What Materials Are Used for Hazardous Area Electrical Enclosures?

Material selection plays a major role in durability, corrosion resistance, and compliance.

Stainless Steel (304 or 316)

Ideal For

Corrosive environments

Offshore oil & gas

Chemical plants

Advantages

High corrosion resistance

Excellent strength

Long service life

Aluminum Alloy

Ideal For

General industrial hazardous locations

Flameproof housings (cast aluminum)

Advantages

Lightweight

Cost-effective

Good thermal dissipation

GRP (Glass-Reinforced Polyester)

Ideal For

Marine environments

High humidity, salt, and UV exposure

Advantages

Corrosion-proof

Lightweight

Non-conductive

Cast Iron

Ideal For

Heavy-duty flameproof enclosures

High-mechanical stress environments

Advantages

Strong impact resistance

High thermal tolerance

Polycarbonate

Ideal For

Intrinsically safe, low-voltage systems

Dust-hazard areas

Advantages

Lightweight

Transparent options available

Resistant to chemicals

Material must match the hazard category, environment, and expected service life.

What Protection Ratings Apply to Hazardous Area Electrical Enclosures?

IP Ratings (Ingress Protection)

The IP code measures dust and water resistance.

| IP Rating | Description |

|---|---|

| IP54 | General dust protection and splash resistance |

| IP66 | Dust-tight, high-pressure washdown protection |

| IP67 | Dust-tight, immersion-resistant |

| IP68 | Dust-tight, long-term immersion protection |

| IP69K | High-temperature, high-pressure cleaning |

Hazardous areas typically require IP66 or higher.

NEMA Ratings (North America)

| NEMA Rating | Protection Level |

|---|---|

| NEMA 3/3R | Outdoor weather-resistant |

| NEMA 4/4X | Corrosion-resistant, washdown, indoor/outdoor |

| NEMA 7 | Explosion-proof (Class I Div 1) |

| NEMA 9 | Dust-ignition proof (Class II) |

ATEX/IECEx Protection Markings

Examples include:

Ex d – Flameproof

Ex e – Increased safety

Ex i – Intrinsically safe

Ex t – Dust protection

Ex p – Pressurized

Understanding these markings ensures proper equipment selection.

How to Select the Right Hazardous Area Electrical Enclosure

Choosing the correct enclosure involves evaluating both environmental and electrical requirements.

Step-by-Step Selection Guide

1. Determine the Hazard Classification

Identify whether the area is Zone 0/1/2 or Class I/II Div 1/2.

2. Identify Internal Equipment

High-energy? Use Ex d

Low-energy/instrumentation? Use Ex i

3. Consider Ambient & Operating Conditions

Heat exposure

Moisture

Chemical corrosion

Mechanical impact

4. Choose Material Based on Environment

Stainless steel → corrosive

GRP → marine

Aluminum → general hazardous areas

Cast iron → heavy duty

5. Determine Required IP/NEMA Rating

Areas exposed to washdown, dust, or water require higher protection.

6. Verify Certification

Ensure ATEX/IECEx/UL/FM compliance for the specific hazard zone.

7. Consider Mounting & Cable Entry

Wall mount, floor mount, pole mount

Metric vs. NPT glands

Pressure equalization valves

Comparison Table: Enclosure Types for Hazardous Areas

| Enclosure Type | Protection Method | Best Applications | Typical Certifications |

|---|---|---|---|

| Flameproof (Ex d) | Contains internal explosion | Motors, starters, switches | ATEX/IECEx, UL, CSA |

| Increased Safety (Ex e) | Prevents arcs, sparks | Terminal boxes, luminaires | ATEX/IECEx |

| Intrinsically Safe (Ex i) | Limits energy to safe levels | Instrumentation, sensors | ATEX/IECEx, UL 913 |

| Pressurized (Ex p) | Positive pressure protection | PLCs, VFDs, computers | ATEX/IECEx |

| Dust-Ignition Protection (Ex t) | Dust exclusion, temp control | Food, grain, pharma | ATEX/IECEx |

Installation Requirements for Hazardous Area Enclosures

Key Installation Considerations

Use certified cable glands and accessories

Maintain flame paths on Ex d enclosures

Ensure pressure systems (Ex p) are calibrated

Monitor enclosure temperatures to avoid exceeding T-ratings

Maintain minimum clearance for heat dissipation

Common Installation Mistakes

Using non-certified glands

Combining IS and non-IS wiring improperly

Modifying enclosure surfaces (invalidates certification)

Incorrect grounding or bonding

Compliance is only maintained when installation follows certified design standards.

FAQs About Hazardous Area Electrical Enclosures

What is the difference between Explosion-Proof and Intrinsically Safe enclosures?

Explosion-proof (Ex d) contains an explosion. Intrinsically safe (Ex i) prevents ignition entirely by limiting energy.

Do hazardous area enclosures need special cable glands?

Yes. Cable glands must match the enclosure type (Ex d, Ex e, Ex t, etc.) and maintain the integrity of the protection concept.

Can GRP enclosures be used in Zone 1 areas?

Yes—if certified. Many GRP enclosures are rated for Zone 1/21, offering corrosion resistance and lower weight.

Does modifying an enclosure affect certification?

Yes. Any drilling, cutting, machining, or altering can void ATEX/IECEx certification unless performed by an approved manufacturer.

What is the best enclosure type for PLCs or electronics?

Pressurized (Ex p) enclosures are ideal because they protect sensitive electronics from hazardous gases or dust.

Conclusion: Choosing the Right Hazardous Area Electrical Enclosures

Hazardous area electrical enclosures are essential for explosion prevention and long-term equipment reliability. By understanding the hazard classification, enclosure types, material characteristics, and protection ratings, you can select an enclosure that meets regulatory requirements and withstands demanding conditions.

Whether you need flameproof housings, intrinsically safe boxes, increased safety terminals, or pressurized control cabinets, choosing correctly ensures compliance, operational integrity, and maximum safety.