Do you need explosion proof lighting at work?

For a business that operates in hazardous environments, equipment and employees consistently experience the threat of potential explosions occurring if safety precaution implementation is inaccurate. For this reason, lighting is an integral part of any business, and understanding how Ex-proof lighting will work in hazardous environments is crucial. Additionally, for any company that operates in hazardous areas, it’s imperative to use Explosion-Proof lighting. By utilizing Ex-Proof lighting, you lower the risk of explosion because caused by dangerous gases like Propane and Methane.

You’ll find that several sectors such as oil refineries, chemical plants, food processing industries, and mines utilize Ex-Proof lighting. And, Standard lighting falls short of overcoming the unique challenges when operating in hazardous areas.

Explosion-Proof Lighting Defined

The designation ‘explosion proof’ doesn’t mean that the lighting fixture will survive explosions or fires fully intact. Instead, it means the light’s design contains sparks that would otherwise cause fire or explosion in confined spaces.

The lighting fixture encases inside a thick frame with extremely robust lenses. Additionally, the case creates a blockage between sparks and other ignition sources like flammable dust, fibers, or vapors that might exist in the environment upon the installed light fixture. Thicker lenses and frames with complex blockages contribute to a more durable and stronger lighting fixture.

Due to the robust design of , the risk of explosions and ignitions occurring are extremely low. As a result, the lighting significantly improves the safety of employees working in hazardous locations as well.

The Benefits

The primary benefit of using Explosion-Proof LED lights over traditional lighting is the energy-efficiency. Specifically, Explosion-Proof LED lights typically consume 90 percent less energy than standard fixtures. The durability of these lights means that they’ll continue to work at their original level of illumination for about 50,000 hours. In some cases, they even last 100,000 hours despite continuous use. Durability and better efficiency reduce maintenance and operating costs.

Installing Explosion-Proof lighting reduces explosive risks by preventing the ignition of flammable gases and vapors in enclosed environments. More importantly, the National Electric Code or the NEC, published by the National Fire Protection Association (NFPA), mandates all lighting equipment used in hazardous locations to be explosion-proof.

Classifications

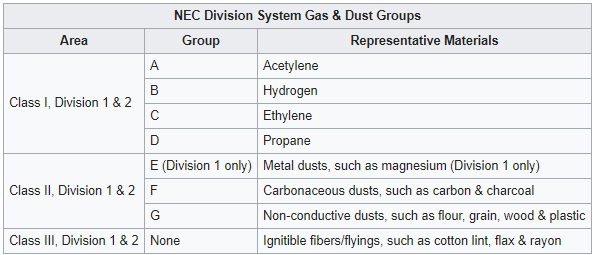

Below are Explosion-Proof classifications specifying the environmental and safety hazard requirements.

Class I, Division 1 area encompasses the combination of Zone 0 and Zone 1 areas.

Zone 0 locations of high concentrations of combustible gases, vapors, dust, or liquids always present for long periods during operations.

Zone 1 locations might have combustible gases, vapors, dust, or liquids present at any time during normal operations.

Class I, Division 2, or Zone 2 are locations that do not have combustible by-products during normal operations. However, concentrations might be present under abnormal conditions, such as sudden leaks. As a general guide, those abnormal conditions should not exceed 10 hours a year.

Non-hazardous or Unclassified locations are classified as neither Class I, Division 1 or Division 2, Zone 0, Zone 1 or Zone 2, or any combination. For instance, aerosol sprays used in commercial or residential areas might have flammable gases, but they are still considered low risk to cause an explosion.