Welcome to Intrinsically Safe Store, your one-stop-shop for all your safety equipment needs. We are dedicated to providing you with the most reliable and up-to-date information on safety standards and requirements. In this article, we will delve into the impact of international standards on Class 1 Division 2 electrical requirements. We invite you to explore our website and contact us for any further inquiries.

Understanding Class 1 Division 2 Electrical Requirements

Class 1 Division 2 (C1D2) is a classification for hazardous locations where flammable gases or vapors may exist under abnormal conditions. This classification is crucial in industries such as oil and gas, chemical, and pharmaceuticals, where the risk of explosions is high. The electrical equipment used in these areas must meet specific safety standards to prevent ignition of these flammable substances.

The Role of International Standards

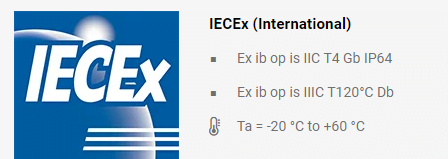

International standards play a pivotal role in ensuring the safety and reliability of electrical equipment used in C1D2 areas. These standards, such as those set by the International Electrotechnical Commission (IEC), provide guidelines for the design, installation, and maintenance of electrical equipment in hazardous locations.

- IEC 60079-0: This standard covers general requirements for electrical equipment in explosive atmospheres.

- IEC 60079-10-1: It provides guidelines for classifying areas where explosive gas atmospheres may occur.

- IEC 60079-14: This standard provides installation and design requirements for electrical systems in hazardous areas.

Impact of International Standards on C1D2 Requirements

International standards have significantly influenced C1D2 electrical requirements in several ways:

Enhanced Safety

Adhering to international standards significantly reduces the risk of explosions in hazardous locations. These standards make sure that we design and install electrical equipment in a way that minimizes the risk of igniting flammable substances.

Global Harmonization

International standards have facilitated the harmonization of safety requirements worldwide. This harmonization makes it easier for companies to comply with safety regulations in different countries, promoting international trade.

Technological Advancements

International standards have also spurred technological advancements in the design of electrical equipment for hazardous locations. These advancements have led to the development of more reliable and safer equipment.

Case Study: The Impact of IEC Standards on C1D2 Requirements

A study conducted by the IEC found that companies that adhered to IEC standards for hazardous locations reported fewer incidents of explosions. These companies also reported a significant reduction in downtime due to equipment failure, leading to increased productivity and profitability.

The impact of international standards on Class 1 Division 2 electrical requirements cannot be overstated. These standards have enhanced safety, facilitated global harmonization of safety requirements, and spurred technological advancements. At Intrinsically Safe Store, we are committed to providing equipment that meets these stringent standards. We invite you to visit our website to explore our wide range of safety equipment. For any further inquiries, please do not hesitate to contact us.