Welcome to Intrinsically Safe Store, your one-stop-shop for all your safety equipment needs. We understand the importance of maintaining a smooth supply chain, especially in hazardous environments like Class 1 Divisions. In this article, we delve into the impact of supply chain disruptions on these divisions and how to mitigate them. Visit our website to learn more about our products and services.

What are Class 1 Divisions?

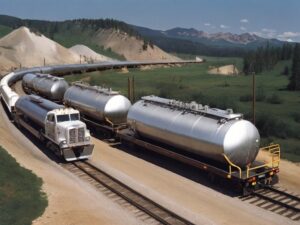

Class 1 Divisions refer to areas where flammable gases, vapors, or liquids exist under normal operating conditions (Division 1) or where such flammable materials may exist due to an accident or abnormal operation (Division 2). These areas require special safety equipment, which is where Intrinsically Safe Store comes in.

The Role of Supply Chain in Class 1 Divisions

The supply chain plays a crucial role in Class 1 Divisions. It ensures the timely delivery of safety equipment, spare parts, and other necessary materials. Any disruption in the supply chain can lead to operational delays, increased costs, and potential safety risks.

Impact of Supply Chain Disruptions

Operational Delays

One of the most immediate impacts of supply chain disruptions is operational delays. For instance, if a shipment of safety equipment is delayed, operations may need to be halted until the equipment arrives, leading to significant downtime.

Increased Costs

Supply chain disruptions can also lead to increased costs. These can come in the form of expedited shipping fees, overtime pay for workers, and lost revenue from halted operations.

Safety Risks

Perhaps the most concerning impact of logistics network disruptions in Class 1 Divisions is the potential for increased safety risks. Without the necessary safety equipment, workers may be exposed to hazardous conditions, leading to potential accidents and injuries.

Case Study: The COVID-19 Pandemic

The COVID-19 pandemic serves as a stark example of the impact of supply chain disruptions. Many companies faced delays in receiving safety equipment due to lockdowns and shipping restrictions, leading to operational delays and increased costs. In some cases, these disruptions also led to increased safety risks.

How to Mitigate Supply Chain Disruptions

While it’s impossible to completely eliminate the risk of supply chain disruptions, there are steps companies can take to mitigate their impact. These include diversifying suppliers, maintaining a stockpile of essential equipment, and implementing a robust supply chain risk management plan.

Supply chain disruptions can have a significant impact on Class 1 Divisions, leading to operational delays, increased costs, and potential safety risks. However, with proper planning and risk management, these impacts can be mitigated. At Intrinsically Safe Store, we understand the importance of a reliable supply chain and are committed to providing our customers with the safety equipment they need, when they need it. Contact us today to learn more about how we can support your supply chain needs.