Refineries are among the most hazardous industrial environments due to the presence of flammable gases, vapors, and combustible dust. In such volatile zones, even a minor spark from uncertified equipment can result in catastrophic incidents. That’s why intrinsically safe equipment is essential.

The term “intrinsically safe” refers to devices that are engineered to operate safely in explosive atmospheres by preventing sparks and limiting energy output. This equipment is tested and certified to meet stringent international safety standards, making it suitable for use in zones where explosions could otherwise occur.

This guide provides an in-depth look at the best intrinsically safe equipment for refineries in 2025, including product types, certifications, and key considerations. Whether you’re overseeing refinery operations, upgrading your safety protocols, or outfitting a new facility, this guide is designed to help you make smart, compliant choices.

Want to equip your refinery with certified intrinsically safe gear?

Explore Intrinsically Safe Equipment for Refineries

What Is Intrinsically Safe Equipment?

Intrinsically safe equipment is designed to operate without igniting hazardous substances in its environment. This is achieved by ensuring the electrical and thermal energy of the device is below the ignition threshold of the materials present.

For refinery applications, such equipment allows daily operations—including communication, inspection, lighting, and data collection—to proceed safely without compromising the safety of workers or infrastructure.

The key principle behind intrinsic safety is that equipment should not be able to generate a spark or high temperature capable of causing an explosion under any fault condition.

Certification Standards for Intrinsically Safe Equipment

When evaluating intrinsically safe tools for refinery use, it’s critical to verify that they meet global safety standards. The primary certifications include:

ATEX (Atmosphères Explosibles)

An EU directive that sets the standard for equipment used in explosive atmospheres. Refineries operating in Europe must comply with ATEX.

IECEx (International Electrotechnical Commission Explosive)

A global certification system that confirms equipment meets international standards for safety in explosive environments.

UL 913 / CSA

Commonly required in North America, these standards validate that equipment is safe for use in Class I, Division 1 or 2 hazardous locations.

Zone and Class/Division Ratings

Zone 0/1/2 (IECEx/ATEX): Define the likelihood of an explosive atmosphere being present.

Class I Div 1/2 (UL/CSA): Similar, but used in North America.

Knowing which zone your equipment will operate in is essential to ensuring compliance.

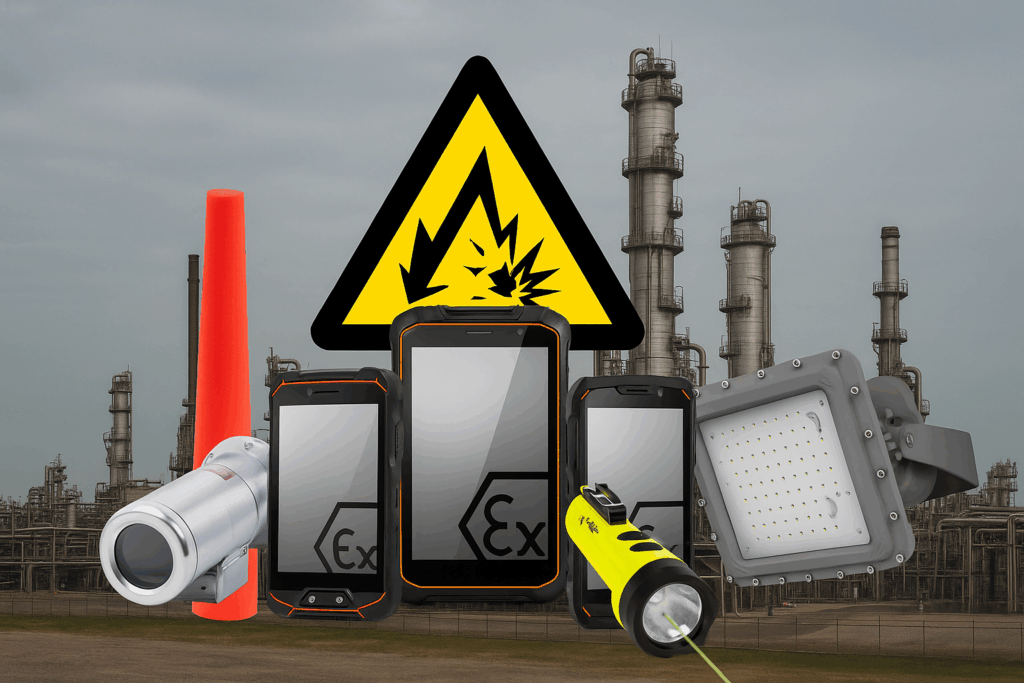

Key Equipment Categories for Refineries

Here’s a breakdown of the most important intrinsically safe equipment categories for refinery operations in 2025:

Intrinsically Safe Mobile Devices

Mobile communication is central to modern refinery management. Workers use devices for real-time reporting, asset tracking, emergency alerts, and workflow optimization.

Features:

Ruggedized designs for extreme temperatures and conditions

ATEX/IECEx Zone 1 or Class I Div 1 certified

Long battery life for extended shifts

Push-to-talk (PTT) and lone worker protection

Android OS for compatibility with industrial apps

Top Products:

i.safe MOBILE IS530.1

Sonim XP8 IS

Explosion-Proof Lighting

Lighting plays a dual role in refineries: ensuring visibility and preventing accidents. Intrinsically safe lighting solutions are crucial in both fixed installations and portable use cases.

Features:

LED technology for efficiency and longevity

Shock-resistant enclosures

Certified for use in explosive gas and dust zones

Rechargeable battery systems for portable units

Types:

Handheld flashlights

Fixed floodlights

These devices are essential for confined spaces, inspection points, and night-shift operations.

Intrinsically Safe Cameras

Cameras play a key role in inspections, documentation, and remote troubleshooting. In high-risk environments, only explosion-proof cameras can be deployed safely.

Features:

4K or HD video capability

Thermal imaging for hot-spot detection

Wi-Fi or LTE-enabled for real-time transmission

Built-in lighting for low-visibility conditions

Use Cases:

Flare stack inspections

Pipeline integrity assessments

Thermal leak detection

These tools reduce the need for human presence in high-risk areas and improve overall inspection efficiency.

Intrinsically Safe Gas Detectors

Early gas leak detection is non-negotiable in refinery settings. These devices provide constant monitoring of combustible and toxic gases, alerting workers before levels become dangerous.

Features:

Real-time multi-gas monitoring

Visible and audible alarms

Compact, wearable designs

Bluetooth and cloud data integration

Commonly Monitored Gases:

Hydrogen sulfide (H₂S)

Carbon monoxide (CO)

Methane (CH₄)

Oxygen (O₂) depletion

The best models offer integration with mobile devices for instant alerts.

Intrinsically Safe Ventilation and Fans

In confined or high-temperature areas, maintaining airflow is critical. Explosion-proof fans and blowers are designed to provide powerful ventilation without posing an ignition risk.

Features:

Sealed explosion-proof motors

Aluminum or corrosion-resistant casings

Static-free fan blades

Safe for Class I Div 1 / Zone 1 areas

Applications include tank maintenance, chemical mixing rooms, and below-grade spaces.

Intrinsically Safe Headsets and Audio Equipment

Clear communication in loud, hazardous environments is critical. Headsets and intercom systems must be safe, rugged, and hands-free.

Features:

Noise-canceling microphones

Intrinsically safe certification for headsets and radios

Integration with two-way radios or mobile devices

Weather-resistant design

Ideal for coordination during shutdowns, turnarounds, or emergency drills.

Equipment Comparison Table

| Category | Certifications | Key Features | Refinery Applications |

|---|---|---|---|

| Mobile Devices | ATEX, IECEx, UL 913 | Rugged, Android, PTT, LWP | Communication, Operations |

| Lighting | ATEX, IECEx | LED, portable, rechargeable | Maintenance, Confined Space Entry |

| Cameras | ATEX, IECEx | HD/4K, thermal, wireless | Inspection, Remote Audits |

| Gas Detectors | ATEX, IECEx | Multi-gas, real-time alerts | Leak Detection, Safety Monitoring |

| Fans and Blowers | ATEX, UL, CSA | Sealed motors, corrosion-resistant | Ventilation, Confined Areas |

| Headsets/Audio | ATEX, IECEx | Noise canceling, rugged | Loud Environments, Emergency Use |

Get expert help selecting the right tools for your refinery.

Schedule a Call With a Safety Specialist

How to Choose the Right Equipment for Your Refinery

Choosing the best intrinsically safe equipment starts with a detailed hazard analysis. Consider:

Zone Classification: Match the certification to the zone where the equipment will be used.

Use Case: Select features that align with daily operations—mobility, range, connectivity, etc.

Maintenance Requirements: Opt for rugged, low-maintenance devices to minimize downtime.

Compatibility: Ensure compatibility with software, communication systems, and data infrastructure.

Training Needs: Pick tools that are intuitive or come with manufacturer support and documentation.

FAQs

What does intrinsically safe mean in refinery environments?

It refers to equipment that limits energy (electrical/thermal) to safe levels, preventing ignition of hazardous gases or dusts.

Can I use regular devices if I’m outside the main processing area?

Only if the area is classified as non-hazardous (safe zone). In classified areas (Zone 0, 1, 2), only certified equipment is allowed.

Are all explosion-proof tools intrinsically safe?

No. Explosion-proof means the device can contain an explosion; intrinsically safe means it prevents one entirely. Both may be used depending on the hazard level.

Do intrinsically safe devices cost more?

Yes, but they offer long-term value through enhanced safety, regulatory compliance, and operational uptime.

What happens if I use non-certified equipment in a refinery?

Using non-compliant equipment in a hazardous area can result in regulatory penalties, equipment damage, or catastrophic accidents.

Ready to future-proof your refinery with certified gear?

Shop Intrinsically Safe Equipment Now

Conclusion

Refinery operations face some of the most demanding safety challenges in any industry. Investing in intrinsically safe equipment is not just about meeting compliance—it’s about protecting lives, infrastructure, and the environment.

From rugged mobile devices to explosion-proof lighting and advanced gas detectors, every piece of certified equipment plays a critical role in maintaining safe, efficient operations.

Ensure your refinery is future-ready and compliant with the highest safety standards by equipping it with the best intrinsically safe equipment of 2025. Every decision you make about safety today sets the foundation for a more secure, productive tomorrow.