Fans

We have a wide selection of explosion proof fans to meet the most stringent requirements. We combine quality manufacturing with testing to ensure that our industrial fan provides you with dependable, safe performance no matter where it is used! Our explosion-proof industrial fans are designed to create airflow in potentially explosive environments, built with high-quality materials, and rigorously tested to meet ATEX and IECEx standards. These fans are ideal for many applications like boilers, chemical processing plants, oil refineries and other industrial plants that require the use of explosion proof equipment.

Showing all 48 results

-

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-73.26441%2041.11407%20-38.18907%20-68.05212%20130%20105)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-253.8683%2023.99762%20-3.28395%20-34.74057%20147%20220)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%2218%22%20cy%3D%2280%22%20rx%3D%2223%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-.3%2019853.7%20-38271.2)%20scale(29.1301%20255.00004)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Atlantic Blowers ABAF-20-110E Explosion Proof Fan

$1,75599 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23626262%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(188.12418%20-47.22214%2018.17612%2072.41027%20112.5%20146.8)%22%2F%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(288.1257%20-79.25802%2016.4642%2059.8521%20198.4%20267)%22%2F%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-93.1%2082.8%20-58)%20scale(32.63595%20298.82815)%22%2F%3E%3Cpath%20fill-opacity%3D%22.5%22%20d%3D%22M251.4.6h49.2V72h-49.2z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Ramfan ECKO Flex Conductive Duct

$8900Price Depends on product optionMake a selection to update price -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%231d0000%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-16.63848%2087.28886%20-95.21658%20-18.14961%20156.4%20129)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-51.25206%206.50762%20-37.64085%20-296.448%2028.4%20186.4)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(31.87019%202.0051%20-18.76357%20298.23843%20274.7%20155.7)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(283.4493%2010.64891%20-.8338%2022.1939%20163%2010.9)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-12-110E

$99563 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23282828%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-60.59603%2022.41515%20-21.00704%20-56.7894%20102.4%20116)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(1.31597%2034.16065%20-206.84658%207.96833%20132.4%20212.8)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(206.71631%2010.83354%20-1.9183%2036.6032%20128.5%2028)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M237.9%20243.5l-65-1%204.2-241%2065%201z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

RamFan EFi150xx – 16″ Explosion Proof Fan

$3,70755Price Depends on product optionMake a selection to update price -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23575757%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(85.60978%205.01928%20-6.61677%20112.85676%20138.8%20137.1)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-174.8%20138.6%2076.7)%20scale(44.25745%20298.82815)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-48%20278.5l10.4-296.3%2086.7%203-10.4%20296.3z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-50.86339%20-294.4676%2040.28006%20-6.95757%20277.1%2081.3)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Canarm SD08-XPF – 8″ Inch Fan Size

$1,55100 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23a7ab98%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(84.96026%203.43384%20-3.96412%2098.08038%20149.9%20145.6)%22%2F%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(37.0199%20-2.27291%2018.31267%20298.26648%20275.6%20147.2)%22%2F%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-29.529%20-1.32357%2013.38082%20-298.5284%2024.5%20100.2)%22%2F%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-2.51945%20-28.79749%20297.69096%20-26.04458%20116.5%20292.4)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

RamFan EFi75xx – 12″ Explosion Proof Fan

$2,65230Price Depends on product optionMake a selection to update price -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(33.4%20-165.4%20300)%20scale(89.76593%2087.41985)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(177.9%20136.4%2072.6)%20scale(43.67494%20298.82809)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(84.5%20-77.8%2094.2)%20scale(298.82813%2036.88197)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-2.84433%2037.4494%20-297.96993%20-22.63118%20128.4%207)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-24-110E

$2,73571 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%231d0000%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-80.66339%20-21.146%2019.0918%20-72.82741%20132.1%20109.1)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-32.53772%20-247.14854%2039.50404%20-5.2008%2025.3%20138.1)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-30.38957%20-3.10647%2025.93141%20-253.67807%20235.2%20146)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22129%22%20cy%3D%2212%22%20rx%3D%22255%22%20ry%3D%2215%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-16-220E

$1,15815 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%238c9272%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-133.6%20114.2%2028)%20scale(64.94092%20112.05211)%22%2F%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(291.85742%20-64.16772%2010.97122%2049.90097%20146.1%20.7)%22%2F%3E%3Cpath%20fill-opacity%3D%22.5%22%20d%3D%22M241.7%20301L278%204.6l79%209.7-36.3%20296.6zM4.1%2028.7l54%20289.5-76.3-24.6z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

RamFan UB20xx – 8″ Explosion Proof Fan

$2,25000Price Depends on product optionMake a selection to update price -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%231c0000%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(105.1%2028.5%20125.1)%20scale(87.06207%2097.33983)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-96.3%20113.1%2087.7)%20scale(298.82812%2044.6563)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-35.39725%20296.72425%20-37.5702%20-4.48188%20281.4%20135.2)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-298.4342%20-15.33855%201.21845%20-23.7068%20185.8%2011)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-12-220E

$99563 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23575757%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(85.60978%205.01928%20-6.61677%20112.85676%20138.8%20137.1)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-174.8%20138.6%2076.7)%20scale(44.25745%20298.82815)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-48%20278.5l10.4-296.3%2086.7%203-10.4%20296.3z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-50.86339%20-294.4676%2040.28006%20-6.95757%20277.1%2081.3)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Canarm SD24-XPF – 24″ Explosion Proof Exhaust Fan

$1,95600 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%239fa09a%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(121.3%2026%20104.4)%20scale(49.77005%2051.1063)%22%2F%3E%3Cellipse%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-5.68018%20247.42703%20-32.06535%20-.73612%20249.9%20123.1)%22%2F%3E%3Cellipse%20cx%3D%229%22%20cy%3D%22132%22%20rx%3D%2220%22%20ry%3D%22255%22%2F%3E%3Cellipse%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-.00988%20-17.71005%20174.38725%20-.09725%20125.6%20255)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

RamFan EFi50xx – 16″ Explosion Proof Fan

$2,70585Price Depends on product optionMake a selection to update price -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-37.06118%20-70.25617%2074.25426%20-39.17023%20128.5%20105.9)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-5.20452%20-39.00603%20252.75993%20-33.72538%20149.7%20219)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(90.1%20-24%2040.1)%20scale(255%2025.44236)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22241%22%20cy%3D%2299%22%20rx%3D%2224%22%20ry%3D%22255%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-32-110E

$3,80000 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-73.1352%20-77.72155%2070.39738%20-66.24322%20143.5%20156.5)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-94.8%20182%20-72.6)%20scale(299.44928%2042.14891)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-296.23689%20-43.74446%205.6732%20-38.41887%2094.3%20279.3)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-18.3%2077.5L3-18.3%20319%203z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-16-110E

$1,15815 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23faae45%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(35.19275%2018.35895%20-25.58817%2049.05063%20117.2%20127.7)%22%2F%3E%3Cellipse%20fill%3D%22%23823f00%22%20cx%3D%226%22%20cy%3D%22236%22%20rx%3D%2216%22%20ry%3D%2221%22%2F%3E%3Cellipse%20fill%3D%22%23985300%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(28.29456%20-6.74366%207.64412%2032.07265%20255%20244)%22%2F%3E%3Cellipse%20fill%3D%22%23fb9839%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(6.98142%20-17.80542%2033.75763%2013.2362%20150%20121.4)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Atlantic Blowers Duct Hose

$41473Price Depends on product optionMake a selection to update price -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23575757%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(85.60978%205.01928%20-6.61677%20112.85676%20138.8%20137.1)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-174.8%20138.6%2076.7)%20scale(44.25745%20298.82815)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-48%20278.5l10.4-296.3%2086.7%203-10.4%20296.3z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-50.86339%20-294.4676%2040.28006%20-6.95757%20277.1%2081.3)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Canarm SD18-XPF – 18″ Inch Fan Size

$1,84500 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%231c0000%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(105.1%2028.5%20125.1)%20scale(87.06207%2097.33983)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-96.3%20113.1%2087.7)%20scale(298.82812%2044.6563)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-35.39725%20296.72425%20-37.5702%20-4.48188%20281.4%20135.2)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-298.4342%20-15.33855%201.21845%20-23.7068%20185.8%2011)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-32-220E

$3,80000 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(57.6%20-31.5%20171.2)%20scale(78.12191%2082.82633)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(253.7699%20-25.01684%203.65295%2037.0554%20147.3%20218.4)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%2215%22%20cy%3D%2297%22%20rx%3D%2226%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(2.22527%20254.99029%20-20.8625%20.18206%20238.2%2083)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-24-220E

$2,73571 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-73.1352%20-77.72155%2070.39738%20-66.24322%20143.5%20156.5)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-94.8%20182%20-72.6)%20scale(299.44928%2042.14891)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-296.23689%20-43.74446%205.6732%20-38.41887%2094.3%20279.3)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-18.3%2077.5L3-18.3%20319%203z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-8-110E

$47508 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23666%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-9.01401%20-254.84063%2048.37827%20-1.7112%20121.7%20134)%22%2F%3E%3Cellipse%20cx%3D%22224%22%20cy%3D%22124%22%20rx%3D%2242%22%20ry%3D%22255%22%2F%3E%3Cellipse%20cx%3D%2227%22%20cy%3D%22136%22%20rx%3D%2236%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%23777%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-58.20156%2015.18845%20-8.54326%20-32.73744%20126%200)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

RAMFAN Quick-Couple Canister for UB20XX

$68500Price Depends on product optionMake a selection to update price -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23575757%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(85.60978%205.01928%20-6.61677%20112.85676%20138.8%20137.1)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-174.8%20138.6%2076.7)%20scale(44.25745%20298.82815)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-48%20278.5l10.4-296.3%2086.7%203-10.4%20296.3z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-50.86339%20-294.4676%2040.28006%20-6.95757%20277.1%2081.3)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Canarm SD12-XPF – 12″ Inch Fan Size

$1,62300 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23e9e9e9%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-97.7511%20-39.1874%2042.62437%20-106.32449%20121%20130)%22%2F%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(21.61295%20-298.04551%2046.31949%203.35889%20275.7%20188.6)%22%2F%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-2.91528%2039.48195%20-298.01682%20-22.00506%20111.9%20275)%22%2F%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-89.7%2073.6%2066.4)%20scale(286.27859%2019.09382)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Ramfan Duct Adapter/Reducer (EC0301)

$30000 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23353535%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(44.0547%2057.00012%20-65.0352%2050.26492%20136%20116.4)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(179.9%2069.6%20115.3)%20scale(255%2035.24271)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%223%22%20cy%3D%22172%22%20rx%3D%2239%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-15.71601%2038.19421%20-221.54116%20-91.15893%20202.3%200)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Axial Explosion Proof Fan Canarm AX16-4″ Inch Fan Size

$2,00671 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23010000%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(100.7%2015.6%20126.2)%20scale(90.86669%2093.50943)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(4.92287%20298.78757%20-36.04878%20.59395%20268%20103.7)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-10%20201l11.8%2096%20316.4-23.4z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(10.8%20-748.8%2073.7)%20scale(34.34017%20298.82815)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-20-220E

$1,75599 -

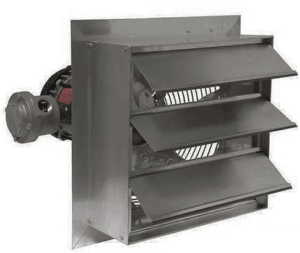

Intrinsically Safe 10-Inch Variable Speed Exhaust Fan with Shutters – 690 CFM Direct Drive (Model: SD10-ECV)

$85000 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-73.1352%20-77.72155%2070.39738%20-66.24322%20143.5%20156.5)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-94.8%20182%20-72.6)%20scale(299.44928%2042.14891)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-296.23689%20-43.74446%205.6732%20-38.41887%2094.3%20279.3)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-18.3%2077.5L3-18.3%20319%203z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-10-110E

$53532 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-73.1352%20-77.72155%2070.39738%20-66.24322%20143.5%20156.5)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-94.8%20182%20-72.6)%20scale(299.44928%2042.14891)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-296.23689%20-43.74446%205.6732%20-38.41887%2094.3%20279.3)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-18.3%2077.5L3-18.3%20319%203z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-10-220E

$53532 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-73.1352%20-77.72155%2070.39738%20-66.24322%20143.5%20156.5)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-94.8%20182%20-72.6)%20scale(299.44928%2042.14891)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-296.23689%20-43.74446%205.6732%20-38.41887%2094.3%20279.3)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-18.3%2077.5L3-18.3%20319%203z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-8-220E

$47622 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23b1496c%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-67.40343%2056.96031%20-47.97325%20-56.76867%20108.8%20121.2)%22%2F%3E%3Cellipse%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(6.3%20-811.6%202198.4)%20scale(44.74411%20255.00002)%22%2F%3E%3Cellipse%20cx%3D%22101%22%20cy%3D%2211%22%20rx%3D%22255%22%20ry%3D%2230%22%2F%3E%3Cellipse%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-3.95503%2033.09494%20-253.19837%20-30.2586%20109.7%20246.8)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Ramfan Tilt Bracket for 16″ EFC/EFi blowers

$76800 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%239fa09a%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(121.3%2026%20104.4)%20scale(49.77005%2051.1063)%22%2F%3E%3Cellipse%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-5.68018%20247.42703%20-32.06535%20-.73612%20249.9%20123.1)%22%2F%3E%3Cellipse%20cx%3D%229%22%20cy%3D%22132%22%20rx%3D%2220%22%20ry%3D%22255%22%2F%3E%3Cellipse%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-.00988%20-17.71005%20174.38725%20-.09725%20125.6%20255)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

RamFan EFi120xx – 16″ Explosion Proof Fan

$3,31500Price Depends on product optionMake a selection to update price -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%237b7b7b%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(3%20-2637%202418.7)%20scale(121.49209%2064.36155)%22%2F%3E%3Cpath%20d%3D%22M-16%202l287-18v129z%22%2F%3E%3Cellipse%20fill%3D%22%23717171%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(22.91443%2069.29625%20-36.30782%2012.00603%20135%2095)%22%2F%3E%3Cellipse%20cx%3D%2285%22%20cy%3D%22243%22%20rx%3D%22255%22%20ry%3D%2233%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

RAMFAN M-E-D, Manhole Entry Device

$4950Price Depends on product optionMake a selection to update price -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%231e1216%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(87.6%201.9%20125.2)%20scale(75.94907%2062.33606)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-19.55886%20253.84674%20-36.23266%20-2.79172%20232.4%20136.2)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(10.63522%20254.77812%20-32.9244%201.37437%2027.7%20166.4)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22146%22%20cy%3D%229%22%20rx%3D%22255%22%20ry%3D%2225%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

RamFan XP500 – 18″ Explosion Proof Fan Motor

$3,52800 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%236f1e39%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-59.60433%201.56938%20-1.98141%20-75.25317%20121.8%20116.1)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20d%3D%22M265-1.5v255h-74v-255z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%2225%22%20cy%3D%22133%22%20rx%3D%2230%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%237e2644%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-4.5%201454.4%20-1481.7)%20scale(23.39033%2038.0812)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

RamFan XP400 – 16″ Explosion Proof Fan Motor

$3,52800 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23460009%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-86.53693%2016.35132%20-14.78075%20-78.22493%20130.8%20126.3)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22144%22%20cy%3D%22233%22%20rx%3D%22255%22%20ry%3D%2229%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-254.99802%20-1.00502%20.09448%20-23.97074%20117.8%2018.7)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(3.11534%20254.98097%20-25.53753%20.31202%209%20124.5)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

RamFan EFC – 16″ Explosion Proof Fan

$2,32890Price Depends on product optionMake a selection to update price -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23575757%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(85.60978%205.01928%20-6.61677%20112.85676%20138.8%20137.1)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-174.8%20138.6%2076.7)%20scale(44.25745%20298.82815)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-48%20278.5l10.4-296.3%2086.7%203-10.4%20296.3z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-50.86339%20-294.4676%2040.28006%20-6.95757%20277.1%2081.3)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Canarm SD10-XPF – 10″ Inch Fan Size

$1,53800 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23a68d8d%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(117.04492%2026.27592%20-18.48783%2082.3532%20147.3%20150.7)%22%2F%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-.31447%20-43.64197%20298.82037%20-2.1532%20167%20276)%22%2F%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(.84536%2027.2706%20-298.68465%209.25893%2073%2020.6)%22%2F%3E%3Cpath%20fill-opacity%3D%22.5%22%20d%3D%22M318.2%20293.6L295.9-18.2l-64.5%20330.5z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Ramfan Static Cord

$14600 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23242424%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-179.7%2065.2%2062.7)%20scale(85.7143%2092.69963)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(39.95068%20.07091%20-.4526%20254.9996%208.3%20128)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(179.9%20119%2066.3)%20scale(26.55735%20254.99998)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22137%22%20cy%3D%22243%22%20rx%3D%22255%22%20ry%3D%2219%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

RamFan AFi50xx – 16″ Explosion Proof Fan

$3,55425 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%2343443b%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-92.74541%20-47.66467%2049.12933%20-95.59533%20145%20159.7)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(296.53584%2036.94246%20-5.41941%2043.50143%20196.7%2027.6)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-54.4968%20293.81686%20-38.77946%20-7.19277%20287.8%20203.1)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-40.7%203l77.3-1.3L42%20300.5l-77.4%201.3z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

RamFan AFi75xx – 12″ Inch Explosion Proof Fan

$2,89275 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23363636%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(27.13776%20-76.6027%20101.08396%2035.81065%20153.5%20115.9)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(143.2%20-27.7%20106)%20scale(60.42732%20113.4431)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(52.9%20-104.1%20386)%20scale(45.34898%20275.86336)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-34.66614%20-32.55367%20110.64183%20-117.82158%2023.7%2015)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Axial Explosion Proof Fan Canarm AX12-4″ Inch Fan Size

$1,91000Price Depends on product optionMake a selection to update price -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23353535%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-43.3253%20-70.43574%2084.36891%20-51.89564%20158.7%20139.2)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(298.8164%20-2.64806%20.38704%2043.6755%20126%20267.4)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(18.10672%20-44.0526%20276.39175%20113.60391%20241.4%203.6)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(35.3484%20-3.63768%2030.59067%20297.25824%2013.8%20136.6)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Axial Explosion Proof Fan Canarm AX14-4″ Inch Fan Size

$2,00036 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23333%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(41.5249%2057.49752%20-67.63821%2048.84855%20134.3%20116)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(175.6%2036.9%20120.4)%20scale(255%2040.95704)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%227%22%20cy%3D%22149%22%20rx%3D%2234%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-11.90801%2028.96337%20-194.22147%20-79.8523%20203.4%2011.8)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Axial Explosion Proof Fan Canarm AX18-4″ Inch Fan Size

$2,05656 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%233b3b3b%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(18.741%2076.77463%20-106.9714%2026.11214%20140%20140.6)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(2.21033%20-40.32686%20298.38027%2016.35432%20163%20268)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(39.3641%2033.73912%20-194.46963%20226.89161%2027.9%2035.9)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(28.8715%200%200%20298.82817%20285.5%2099.4)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Axial Explosion Proof Fan Canarm AX20-4″ Inch Fan Size

$2,11002 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(41.21213%20-76.22025%2079.39607%2042.9293%20138.4%20140.2)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(87.6%2069.7%20205)%20scale(298.82813%2040.26904)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-77%2018.1L34.1.5l44%20277.8-111%2017.6z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(1.2154%20-27.56725%20298.53812%2013.16205%20151.3%2017.5)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-28-110E

$2,96546 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.20703)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%234f4f4f%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-66.10544%20-43.99853%2049.54782%20-74.44296%20118%20138.1)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22232%22%20cy%3D%22153%22%20rx%3D%2222%22%20ry%3D%22248%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-13.56285%20-42.6544%2099.79184%20-31.73087%20192.8%20255)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-85.4%2022%202.1)%20scale(75.52614%2030.22892)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Axial Explosion Proof Fan Canarm AX24-4″ Inch Fan Size

$2,23000 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(54.55268%20-56.887%2059.47522%2057.03469%20122.7%20112.7)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(34.37686%20.36%20-2.6703%20254.98603%20237%20122.4)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-97.1%2062.5%2054)%20scale(247.4661%2034.40349)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22114%22%20cy%3D%2210%22%20rx%3D%22255%22%20ry%3D%2217%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-18-110E

$1,33432 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23010000%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(23.40396%20-71.27153%2078.76856%2025.86581%20118.7%20116)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22229%22%20cy%3D%22100%22%20rx%3D%2232%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-1.98768%20-254.99225%2027.15558%20-.21168%2015.4%2080)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20d%3D%22M258.6%20265.5l-254.9%209-2.3-66%20254.9-9z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-32-460E

$4,69285 -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%231c0000%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(105.1%2028.5%20125.1)%20scale(87.06207%2097.33983)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-96.3%20113.1%2087.7)%20scale(298.82812%2044.6563)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-35.39725%20296.72425%20-37.5702%20-4.48188%20281.4%20135.2)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-298.4342%20-15.33855%201.21845%20-23.7068%20185.8%2011)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-28-220E

$3,03695 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-130.5%2088%2028.3)%20scale(81.62325%2078.53566)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(4.72101%20-254.9563%2037.36858%20.69195%20235.3%20114)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(21.35607%20252.70412%20-30.31273%202.56173%2021.5%20144.7)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22132%22%20cy%3D%2210%22%20rx%3D%22255%22%20ry%3D%2217%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Explosion Proof Fan Atlantic Blowers ABAF-18-220E

$1,33432