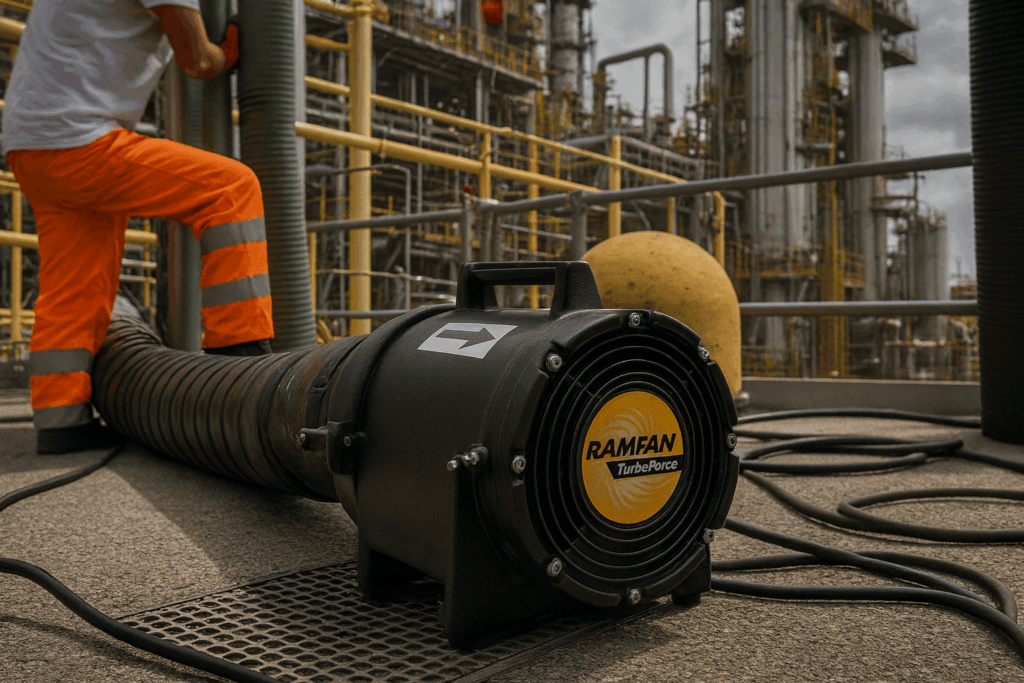

Confined space ventilation is one of the most critical safety measures in hazardous industrial environments. Whether entering tanks, tunnels, silos, pipelines, or processing vessels, workers must have reliable airflow that removes toxic gases, displaces flammable vapors, and maintains oxygen levels. When these work zones fall under ATEX or explosive-atmosphere classifications, only a certified ATEX portable ventilator can be used safely.

This guide explores airflow performance, pricing, lead times, certifications, and real-world applications of ATEX-rated portable ventilators. We also compare the two available models from the Intrinsically Safe Store to help safety managers, industrial hygienists, and confined-space specialists choose the right solution for their environments.

What Is an ATEX Portable Ventilator?

An ATEX portable ventilator is a mobile air-moving device engineered for safe operation inside potentially explosive atmospheres. It prevents ignition by ensuring that all electrical, mechanical, and thermal components meet strict ATEX (ATmosphères EXplosibles) standards for EU hazardous locations.

These ventilators are essential in:

Confined spaces with combustible gases

Petrochemical manufacturing

Chemical tank cleaning

Underground utilities

Fuel handling and storage areas

Pharmaceutical manufacturing

Food and grain processing (dust hazards)

ATEX ventilators ensure that workers can enter confined spaces without the threat of vapor buildup or ignition.

Why Are ATEX Portable Ventilators Required in Confined Spaces?

ATEX compliance is not optional in classified zones. Confined spaces increase the risk of:

Accumulated flammable vapors

Oxygen deficiency

Stratified gases (heavier-than-air hazards)

Lack of natural air exchange

Looking for certified ATEX portable ventilators for confined-space operations?

Browse ATEX-Certified VentilatorsA non-approved ventilator could generate sparks or heat capable of igniting an explosive atmosphere. ATEX portable ventilators are engineered to avoid such ignition risks through:

Spark-free design

Ensuring no internal electrical component can produce ignition.

Anti-static housing

Prevents the buildup of charge across the fan’s exterior.

Explosion-proof motors

Encased motors prevent arcs from reaching the atmosphere.

Temperature control

Maximizes safety by keeping surface temperature below ignition thresholds.

Need to ensure full compliance for confined-space ventilation?

Read Confined-Space Safety Compliance GuideWhat Certifications Should an ATEX Portable Ventilator Have?

A compliant ATEX portable ventilator typically carries markings for:

ATEX Directive 2014/34/EU

Defines equipment categories for explosive atmospheres.

Zone Classification

Most ventilators are certified for:

Zone 1: Likely presence of explosive atmosphere

Zone 2: Unlikely, but possible under abnormal operation

Gas and Dust Groups

Look for categories such as:

II 2G Ex h IIB T4 Gb (gas)

II 2D Ex h IIIC T135°C Db (dust)

Ingress Protection Ratings

ATEX fans often include IP55 or better to prevent dust and moisture ingress.

What Are the Available ATEX Portable Ventilators at IntrinsicallySafeStore.com?

According to your product list, the category currently includes:

1. Curtiss-Wright COPPUS Double-Duty Heat Killer Ventilator

Price: $7,250.00

Type: High-volume industrial ventilator

Applications: Cooling, confined-space ventilation, and hot-work support

2. Curtiss-Wright COPPUS CADET® VAC & VEP Portable Ventilators

Price: $2,194.10

Type: Compact portable ventilator

Applications: Confined-space entry, localized fume extraction, tank work

These models are engineered for harsh industrial conditions and known for exceptional airflow, rugged construction, and compliance with industrial safety standards.

What Airflow Capacities Do ATEX Portable Ventilators Offer?

Airflow is the defining performance metric for any ventilation system. It determines how quickly a confined space can be purged of toxic gases, fumes, odors, or dust.

Here are general airflow expectations:

Small to Medium ATEX Ventilators (8–12 in.)

1,000–3,500 CFM

Suitable for tunnels, tank entries, and pipelines.

Large Industrial Ventilators (16–24 in.)

6,000–11,000+ CFM

Ideal for process plant rooms, vessel cooling, and high-head applications

Although exact airflow specifications vary by model, COPPUS ventilators are widely recognized for delivering some of the industry’s highest performance levels.

Comparison Table: ATEX Portable Ventilators

| Feature | COPPUS Double-Duty Heat Killer | COPPUS CADET® VAC & VEP |

|---|---|---|

| Price | $7,250.00 | $2,194.10 |

| Ventilator Type | High-capacity mobile ventilator | Compact portable ventilator |

| Typical Airflow | High CFM for large spaces | Moderate CFM for confined spaces |

| Best Application | Cooling hot work areas, vessel ventilation, industrial air movement | Confined-space entry, fume extraction, tank work |

| Mobility | Heavy-duty wheeled frame | Lightweight, portable |

| Certifications | Manufacturer-verified explosion-safe design | Manufacturer-verified explosion-safe design |

| Use Cases | Refineries, chemical plants, shipyards | Utilities, tank cleaning, underground work |

Compare all explosion-proof ventilators to choose the right solution.

Explore Explosion-Proof FansWhich ATEX Portable Ventilator Is Best for Confined Spaces?

The CADET® VAC & VEP Portable Ventilator stands out as the ideal confined-space solution due to its:

Lightweight body

High airflow relative to size

Portability

Capability to attach ducts

Lower power draw

For applications requiring cooling, heat control, or large-volume ventilation, the Double-Duty Heat Killer is the better choice.

What Are Typical Lead Times for ATEX Portable Ventilators?

Lead times for hazardous-area equipment vary widely. For ATEX portable ventilators, typical fulfillment ranges are:

Standard Lead Time

2–6 weeks depending on inventory and configuration.

Factors Affecting Lead Times

Certification batch schedules

Manufacturing workload

Custom accessories (ducting, hoses, couplings)

Shipping destination (especially offshore or remote areas)

Expedited Shipping

Many industrial buyers request rush delivery, especially for tank turnaround operations, shutdowns, and emergency ventilation. Lead times may shorten when units are in stock.

What Accessories Improve ATEX Portable Ventilator Performance?

Common accessories that enhance airflow efficiency and safety include:

Flexible Ducting

Directs clean air into tight confined spaces like ship holds or pipelines.

Anti-Static Ducting

Required when dealing with combustible dust or vapor atmospheres.

Adapters and Reducers

Let one ventilator serve multiple entry points.

Hoses and Fume Extractors

Ideal for welding, painting, and tank degassing.

How Do You Choose the Right ATEX Portable Ventilator?

Use these criteria to select the correct unit for your confined-space job:

1. Required Airflow

Estimate CFM based on the volume of the space and hazard concentration.

2. Zone Classification

Verify ATEX ratings relevant to your work area.

3. Portability Requirements

Small, lightweight ventilators are ideal for tank entries and underground use.

4. Cooling Needs

Heat-intensive work requires larger ventilators.

5. Hose Length

Long ducting may reduce airflow, requiring higher-powered models.

Best Choice by Industry

Oil & Gas

Best: COPPUS Double-Duty Heat Killer

Handles vessel degassing, confined-space entry, and process room cooling.

Chemical Processing

Best: CADET VAC & VEP

Perfect for drum cleaning, tank entry, and fume removal.

Utilities

Best: CADET VAC & VEP

Lightweight for underground manhole and tunnel ventilation.

Maritime & Shipyards

Best: Double-Duty Heat Killer

High-volume ventilation for tanks, hulls, and maintenance rooms.

Not sure which ATEX ventilator is best for your confined-space operation?

Request a Quote for ATEX VentilatorsFAQs About ATEX Portable Ventilators

What makes a ventilator ATEX certified?

An ATEX portable ventilator is designed to limit electrical and mechanical ignition sources. It uses anti-static housing, explosion-proof motors, and temperature-controlled components.

Can I use a non-ATEX ventilator in a confined space?

No—if the atmosphere is classified as hazardous or explosive, only ATEX-rated equipment is permitted for safety compliance.

How much airflow do I need for confined-space entry?

Many safety guidelines recommend 20–30 air changes per hour, which can range from 1,000 to 7,000+ CFM depending on the space.

Are ATEX portable ventilators heavy?

Some high-capacity units weigh more, but smaller models like the CADET® portable ventilators are designed for easy transport and single-person operation.

How long do ATEX ventilators last?

With proper maintenance, ATEX ventilators often last 10–15 years in industrial environments.

Conclusion

Confined-space safety begins with proper ventilation, and using the right atex portable ventilator ensures compliance, ignition protection, and dependable airflow. Whether you require a compact, portable solution like the Curtiss-Wright COPPUS CADET® VAC & VEP or high-capacity air movement from the Double-Duty Heat Killer, choosing the correct unit improves worker safety and operational efficiency. Understanding airflow performance, pricing, and lead times helps organizations prepare for shutdowns, tank entries, and emergency response scenarios without delay.