Confined spaces are some of the most dangerous work environments in industrial settings. Tight quarters, poor ventilation, and potential gas accumulation make them a hotspot for accidents. According to OSHA, confined space incidents often result in severe injuries or fatalities due to hazardous atmospheres or inadequate equipment.

That’s why confined space safety starts with proper preparation—and most critically, with the right certified equipment. Intrinsically safe devices are specifically engineered to operate safely in explosive or flammable environments. In this post, we explore how these tools help teams meet compliance, minimize risk, and enhance operational efficiency.

We’ll also dive into what intrinsically safe certification means, what tools are essential in confined spaces, and how to implement a practical safety checklist at your site.

What Is a Confined Space?

A confined space is defined by OSHA as any area that:

Is large enough for a worker to enter and perform tasks

Has limited entry or exit points

Is not designed for continuous occupancy

Examples include:

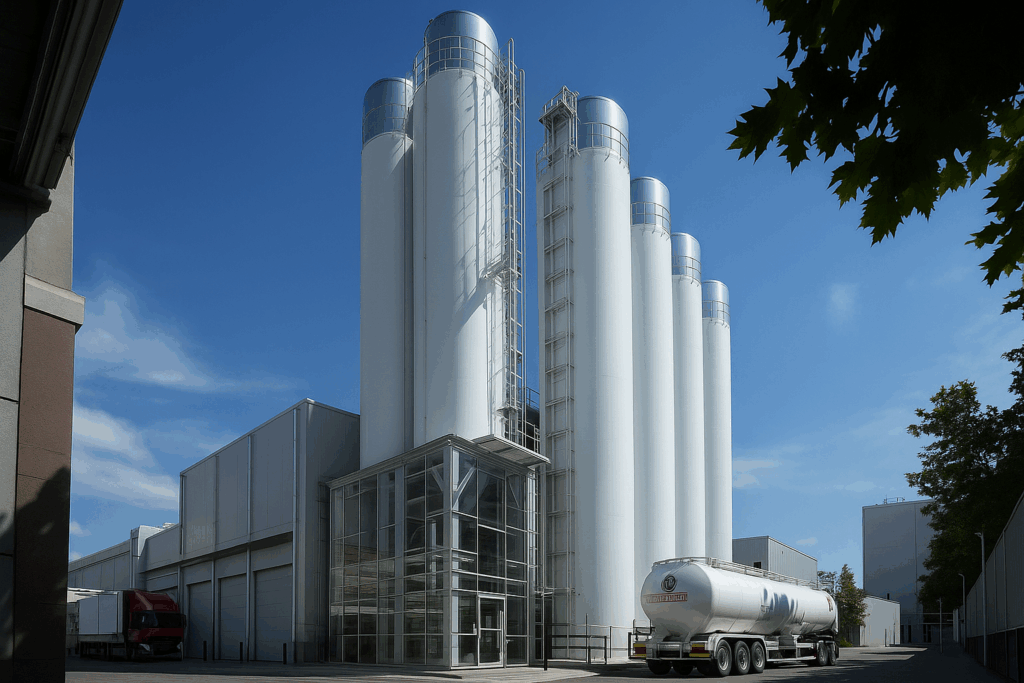

Storage tanks

Silos

Utility vaults

Pipelines

Tunnels

These environments pose unique risks that demand proactive safety protocols and intrinsically safe tools.

Why Intrinsically Safe Devices Are Required

In confined spaces with explosive gases, vapors, or combustible dusts, even a minor spark from standard electronics can trigger a catastrophe. Intrinsically safe (IS) devices are designed to limit electrical energy and thermal output to prevent ignition under fault conditions.

Compliance Standards:

| Certification | Purpose | Coverage |

|---|---|---|

| ATEX / IECEx | Explosion prevention | Required in Zones 0, 1, 2 |

| UL/CSA | North American safety ratings | Class I, Div 1 & 2 environments |

| OSHA 29 CFR 1910.146 | Confined space entry standards | Requires hazard assessment and proper PPE/tools |

Using IS-rated tools is not just smart—in most cases, it’s legally required.

Understanding Intrinsic Safety: The Science Behind It

Intrinsic safety is based on limiting the energy available for ignition. Even if a device malfunctions, it cannot create enough heat or spark to ignite a hazardous atmosphere. The circuits inside IS equipment are designed to operate below the ignition threshold of flammable gases and vapors.

Key Engineering Characteristics:

Reduced voltage and current

Heat dissipation structures

Hermetically sealed enclosures

Rigorous third-party testing and labeling

IS devices are also often paired with fail-safe alarms, rugged enclosures, and communication redundancy to ensure operational integrity in worst-case scenarios.

Essential Intrinsically Safe Tools for Confined Space Safety

1. Lighting: Navigating Confined Areas Safely

Adequate lighting is essential for visibility in dark or sealed spaces. Regular flashlights can spark or overheat, but IS-certified lighting reduces that risk.

Recommended Products:

| Product | Certification | Features | Price |

|---|---|---|---|

| Nightstick XPP-5452G Headlamp | ATEX / IECEx | Dual light, waterproof, helmet-compatible | $61.50 |

| Bayco SLR Rechargeable LED Work Light | Class I Div 1 | Hook-mounted, spot/flood light modes | $45.45 |

Lighting must be hands-free or easy to mount inside vertical entries like manholes or tanks. The Bayco SLR’s hook system is ideal for hanging from overhead structures.

2. Gas Detectors: Monitoring the Air You Breathe

Toxic and flammable gases are silent killers in confined environments. Real-time monitoring is vital for assessing oxygen levels, explosive limits, and toxic substance concentration.

Recommended Products:

| Product | Detection Type | Features | Price |

|---|---|---|---|

| SENKO SGT Portable Detector | H2S, CO, O2, Combustibles | Compact, audible alarms, single gas focus | $382.34 |

| Ion Science Tiger LT VOC Detector | VOCs | Fast response, IS-certified, data logging | $3,928.61 |

Make sure to calibrate detectors before each use. The Ion Science Tiger LT offers extensive logging and connectivity features for inspections and incident documentation.

3. Communication & Compliance Devices

Teams must stay connected in real time. Mobile devices used in confined spaces must be rugged and intrinsically safe. Live video, audio, and data tracking improve situational awareness and response time.

Recommended Products:

| Device | Certification | Use Case | Price |

|---|---|---|---|

| Xciel iPhone 14 ATEX Zone 2 | Zone 2 Certified | Field data entry, emergency alerts | $837.00 |

| Ecom Tab-Ex 03 D2 Tablet | Div 2 / ATEX Zone 2 | Inspection reports, live video, remote monitoring | $1,845.33 |

These devices are ideal for use with safety apps, confined space permit software, and remote technical assistance.

Want help choosing the right tools for your confined space work?

Speak to a Safety Expert

How Intrinsically Safe Devices Improve Compliance

Using IS devices supports compliance with:

OSHA 29 CFR 1910.146 (Permit-Required Confined Spaces)

NEC Article 500 (Hazardous Locations)

NFPA 70E Electrical Safety in the Workplace

Employers must provide tools that eliminate or control recognized hazards. Documented use of IS devices strengthens legal defensibility and reduces insurance risk.

Benefits of Intrinsically Safe Equipment in Confined Spaces

Why does it matter?

Explosion prevention: Limits the chance of ignition in volatile atmospheres.

Compliance assurance: Meets OSHA, NEC, and global safety standards.

Durability: Built for rugged use in extreme conditions.

Real-time communication: Enables faster response to emergencies.

Worker confidence: Improves morale and safety culture.

FAQs About Confined Space Safety

What makes a space “confined” according to OSHA?

It must be large enough to enter, have restricted entry/exit, and not meant for continuous occupancy.

Are gas detectors legally required?

Yes. OSHA requires atmospheric testing before entry and continuous monitoring for any space with potential hazards.

Can I use a regular smartphone in a confined space?

No. Only ATEX/IECEx/Div-certified devices can be used in classified hazardous areas.

What happens if I use non-IS tools in Zone 0?

You risk severe fines, operational shutdowns, or even fatalities due to ignition. Always verify certifications.

How do I know if a device is intrinsically safe?

Check for markings like ATEX, IECEx, or Class I Div 1 on the product. Products on Intrinsically Safe Store clearly display this information.

Final Safety Checklist for Confined Space Work

Before entering:

Calibrate gas detectors

Test for oxygen, combustibles, and toxins

Equip IS-certified flashlights or headlamps

Verify communication tools are ATEX/IECEx approved

- Use trained attendants and retrieval systems

Complete permit and hazard review

Document equipment usage for compliance audits

Conclusion

Confined spaces are inherently hazardous. But with proper planning, training, and intrinsically safe gear, you can ensure both regulatory compliance and worker safety.

Intrinsically safe lighting, gas detectors, and mobile tools are vital components in every confined space entry kit. From real-time alerts to post-job reporting, these tools deliver performance without compromising safety.