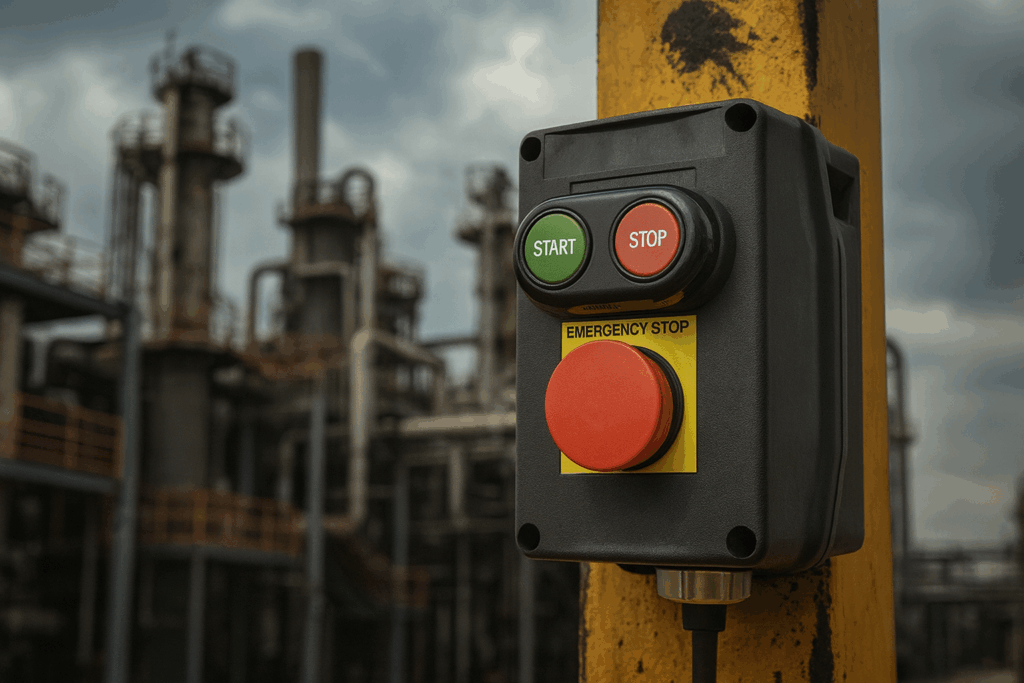

Emergency stop (E-stop) devices are fundamental to industrial safety. They allow operators to immediately halt equipment when a hazard is detected, reducing risks of injury, equipment damage, and process escalation. In hazardous locations, however, an E-stop must do more than shut down machinery—it must do so without introducing an ignition source. That is why the explosion proof emergency stop station is a critical component in oil and gas, chemical processing, refining, mining, pharmaceuticals, and other industries with explosive gases or dusts.

This guide explains how explosion-proof E-stops function, what certifications they require, enclosure considerations, placement rules, and wiring best practices to ensure safety and compliance.

What Is an Explosion-Proof Emergency Stop Station?

An explosion proof emergency stop station is a control device housed inside a certified enclosure designed to prevent internal sparks or arcs from igniting surrounding hazardous atmospheres. While a standard E-stop provides a mechanical means of stopping equipment, an explosion-proof model ensures that any electrical switching, fault condition, or internal failure remains contained.

Choose the right enclosure for a compliant E-Stop system

Explosion-proof E-stops depend on certified housings that contain faults and preserve flame paths. If you’re planning a shutdown station for hazardous locations, start by selecting the correct enclosure strategy.

Core Functions of an Explosion-Proof E-Stop

Provide an immediate manual shutdown of connected equipment

Break control or power circuits safely in hazardous areas

Withstand internal electrical faults without igniting gases or dust

Maintain safety integrity even during component failure

Clearly signal emergency operation through a red, latching pushbutton

Explosion-proof E-stops are used on pumps, conveyors, mixers, hoists, packaging lines, cranes, and process equipment across many hazardous facilities.

Why Hazardous Areas Require Explosion-Proof E-Stops

Why is an explosion proof emergency stop station necessary?

Hazardous areas classified as Class I/II/III or ATEX Zones contain gases, vapors, or dust that can ignite from minor electrical activity. Pushbuttons and switches inherently produce arcs during activation. If housed in a standard enclosure, these arcs could ignite the atmosphere. Explosion-proof stations prevent this through flameproof or increased-safety design.

Common Hazards That Make E-Stops Critical

Pressurized flammable gas releases

Chemical spills or vapor emissions

Mechanical equipment failure

Conveyor jams or blade blockages

Overheating of motors or pumps

Worker entanglement or near-miss events

Explosion-proof E-stops allow workers to stop processes instantly while ensuring the stop device itself cannot trigger combustion.

Understanding Certifications for Explosion-Proof E-Stops

What certifications should an explosion-proof E-stop have?

Selecting a compliant station starts with verifying the correct hazardous-location approvals. These certificates define where and how the equipment may be used.

ATEX Certifications

Explosion-proof stations used in the European Union must comply with ATEX Directive 2014/34/EU.

ATEX Zones

Zone 0: Continuous hazardous atmosphere

Zone 1: Likely hazardous atmosphere during normal operation

Zone 2: Rare presence of explosive atmosphere

Typical marking example:

II 2G Ex d IIC T6 Gb

IECEx Certification

IECEx ensures global harmonized standards and testing. Many international facilities require both IECEx and ATEX markings for equipment traceability and global acceptance.

North American NEC/CEC Class/Division System

Used in the United States and Canada:

Class I: Flammable gases and vapors

Class II: Combustible dust

Class III: Fibers and flyings

Division 1: Hazard likely present

Division 2: Hazard present only during abnormal operation

Appropriate approvals depend on the specific industrial environment.

Temperature Classes and Gas Groups

E-stop stations must meet temperature and gas group requirements:

T1–T6 temperature codes limit surface temperature

Gas groups IIA, IIB, IIC define allowable environments with increasing risk

Dust groups IIIA, IIIB, IIIC address particle-based ignition hazards

Checking these details is essential to ensure the device is safe for the intended area.

Enclosure Requirements for Explosion-Proof E-Stops

What enclosure features matter most for an explosion-proof emergency stop station?

The enclosure is the heart of explosion protection. It must withstand internal ignition, dissipate heat, and maintain certified flame paths.

Key Enclosure Design Elements

Flameproof Construction (Ex d)

Heavy-duty metal housings (aluminum, steel, or stainless steel)

Precisely machined flame paths that cool escaping gases

Strong threaded or bolted joints

Increased-Safety Enclosures (Ex e)

No arcs or sparks allowed inside

Reinforced insulation and component spacing

High ingress protection (IP66–IP67)

Dust-Ignition-Proof Enclosures (Ex tb)

Prevent dust infiltration or ignition

Maintain surface temperatures below dust ignition limits

Mechanical Protection Ratings

Explosion-proof enclosures typically include:

IP65–IP67 ingress protection

Impact resistance to withstand industrial abuse

Corrosion-resistant finishes for chemical or marine environments

Wide temperature range performance for outdoor or extreme climates

Operational Interface Requirements

Large red mushroom-style pushbutton

Latching (twist or pull-to-reset) operation

Shrouded or guarded designs to avoid accidental activation

Optional illumination or integrated pilot lights (if certified)

Build a quote-ready E-Stop control setup

A robust hazardous-area shutdown design often includes certified junction boxes and signal protection components that support clean, compliant wiring and safer control-loop integration.

Best Practices for E-Stop Placement in Hazardous Areas

How should an explosion-proof emergency stop station be positioned?

Correct placement ensures operators can reach the E-stop quickly during emergencies. Standards such as ISO 13850 and IEC 60204-1 help define positioning requirements.

Placement Principles

Accessibility

Install stations at arm’s reach from operating positions

E-stops must be visible, unobstructed, and clearly identified

Stations should not require bending, climbing, or reaching through machinery

Line-of-Sight Requirements

Technicians must be able to see what they are stopping. Misplaced E-stops can create unintended hazards.

Height and Orientation

Typical installation height ranges from 34–51 inches above the floor to accommodate a wide range of operators.

Clustering and Distributed Locations

Complex machinery may require multiple emergency stop points along:

Conveyor lines

Catwalks

Pump skids

Valve manifolds

Reactor zones

Hazard-Based Location Strategy

Place E-stops near known hazard points

Install additional units in areas with rapid-change operations

Include stations near maintenance access points for safety during servicing

Wiring and Installation Best Practices

What wiring rules apply to explosion-proof emergency stop stations?

Wiring in hazardous areas must meet strict mechanical and electrical safety standards. Any improperly sealed cable or conduit may transmit ignition between equipment or allow flammable gas ingress.

Cable Entry Requirements

Use Ex-certified cable glands (Ex d, Ex e, Ex tb as applicable)

Maintain minimum thread engagement for flameproof fittings

Only use certified reducers, adaptors, or stopping plugs

Conduit and Cable Protection

Seal off conduit entries as required by code

Prevent gas migration through cable sheaths

Maintain grounding and bonding continuity

Support cables to reduce vibration stress

Internal Wiring Requirements

Maintain creepage and clearance distances

Prevent wiring from obstructing flame paths

Use insulated conductors approved for hazardous areas

Safety Circuit Integration

Explosion-proof E-stops must be integrated into a compliant safety control system. Typical scenarios include:

Direct control circuit interruption

Integration with Safety PLC or functional safety systems

Redundant channel wiring for SIL-rated systems

Fail-safe design ensuring de-energized safe state

Comparison Table: Standard vs. Explosion-Proof E-Stop Stations

| Feature | Standard E-Stop | Explosion-Proof E-Stop |

|---|---|---|

| Hazardous Area Placement | Not allowed | Approved for Ex zones |

| Enclosure Type | Plastic/metal | Flameproof or Ex e/tb certified |

| Ignition Safety | Not protected | Prevents ignition under fault |

| Certifications | Basic electrical | ATEX, IECEx, NEC/CEC |

| Wiring Requirements | Standard | Ex-rated with sealing |

| Use Case | General industry | Hazardous locations |

Industry Use Cases for Explosion-Proof E-Stop Stations

Explosion-proof E-stop systems are used across industries where flammable atmospheres exist and rapid shutdown is essential.

Oil & Gas

Drilling rigs

Compressor stations

Refinery processing units

Chemical & Petrochemical

Reactors

Distillation and blending units

Tank farms and loading racks

Mining

Underground equipment

Crushers, conveyors, and dust-prone operations

Food & Grain Processing

Mills, silos, and grain elevators with combustible dust

Pharmaceuticals

Powder handling

Solvent-based processing areas

Water Treatment & Utilities

Chlorine rooms

Methane-prone wastewater operations

Across these industries, explosion-proof E-stops support safe, compliant shutdown procedures.

Need help specifying the right hazardous-area solution?

If you’re selecting an explosion-proof E-stop station, enclosure, or related control components, our specialists can help you validate ratings, installation fit, and compliance requirements before you request a quote.

FAQs About Explosion-Proof Emergency Stop Stations

Are explosion-proof E-stops the same as intrinsically safe E-stops?

No. Explosion-proof E-stops prevent ignition by containing internal explosions, while intrinsically safe devices limit energy to prevent ignition. E-stops typically require explosion-proof or increased-safety designs because they involve switching that may arc.

Can explosion-proof E-stops be installed outdoors?

Yes. Many models offer IP66–IP67 protection and corrosion-resistant housings meant for outdoor hazardous areas.

Do E-stops require regular inspection?

Yes. Inspections must verify flame paths, cable gland torque, gasketing (if applicable), proper labeling, and correct safety circuit performance.

Can a single E-stop control multiple machines?

Yes, if integrated properly into the safety control architecture. However, each machine zone typically requires its own E-stop for visibility and accessibility.

Do explosion-proof E-stops require special maintenance?

Routine maintenance includes checking for corrosion, ensuring all screws remain properly torqued, inspecting flameproof joints, and verifying circuit continuity.

Conclusion

Choosing the right explosion proof emergency stop station is essential for protecting workers and maintaining compliance in hazardous facilities. Proper enclosures, correct hazardous-area certifications, optimized placement, and compliant wiring practices all contribute to a reliable emergency shutdown system. In environments where flammable gases or dusts are present, a standard E-stop cannot provide the necessary protection—only certified explosion-proof equipment ensures safe operation.

Explosion-proof E-stops reduce risk, improve safety response times, and support regulatory compliance across industries. When selecting equipment, it’s essential to consider certification markings, environmental durability, enclosure construction, and integration with safety circuits.