When it comes to operating in dusty environments, visibility is a critical factor. This is where the role of intrinsically safe lighting comes into play. At Intrinsically Safe Store, we understand the importance of designing lighting solutions that not only ensure safety but also enhance visibility in challenging conditions. In this article, we delve into the intricacies of designing intrinsically safe lighting for dusty environments. We invite you to explore our website and discover our range of intrinsically safe products.

Understanding Intrinsically Safe Lighting

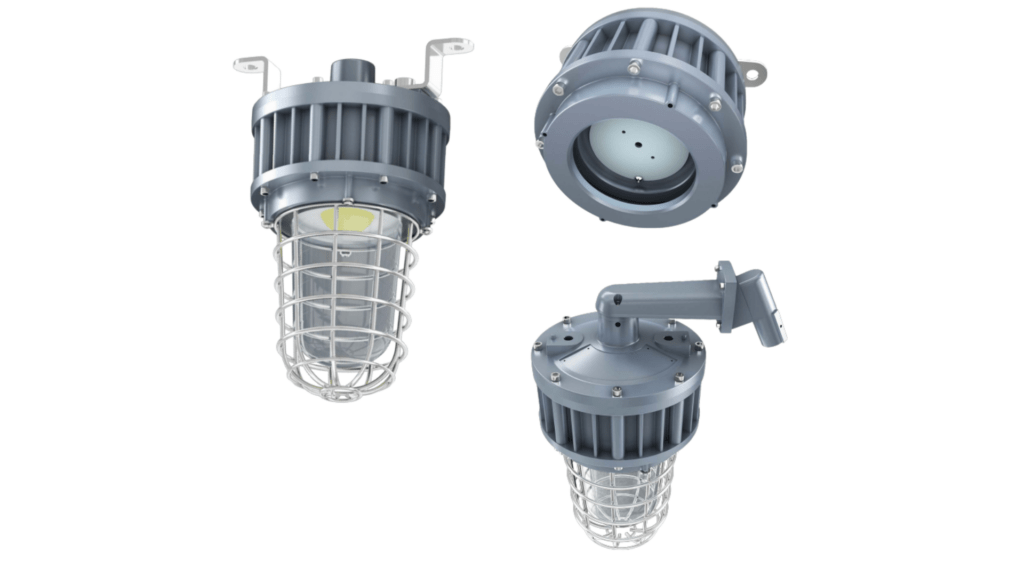

Intrinsically safe lighting is designed to operate in hazardous environments without causing ignition. These lighting solutions are engineered to limit electrical and thermal energy to a level below what is required to ignite a specific hazardous atmospheric mixture.

The Challenge of Dusty Environments

Dusty environments pose unique challenges for lighting design. Dust particles can scatter light, reducing visibility and making tasks more difficult. Moreover, in certain industries, dust can be combustible, adding an extra layer of risk.

Key Considerations in Designing Intrinsically Safe Lighting

- Light Intensity: The lighting solution must provide sufficient illumination to ensure visibility despite the dust.

- Beam Angle: A wider beam angle can help disperse light over a larger area, reducing the impact of dust scattering.

- Color Temperature: Warmer light (lower color temperature) tends to scatter less than cooler light (higher color temperature).

- Enclosure Design: The enclosure must be designed to prevent dust ingress, ensuring the longevity of the lighting solution.

Case Study: Intrinsically Safe Lighting in Mining

A prime example of the need for intrinsically safe lighting in dusty environments is the mining industry. Mines are often filled with dust, and the risk of combustible gases makes safety a paramount concern. Intrinsically safe lighting solutions, such as those provided by the Intrinsically Safe Store, have proven invaluable in these settings, ensuring visibility and safety for workers.

Statistics Highlighting the Importance of Safe Lighting

According to the National Institute for Occupational Safety and Health (NIOSH), poor visibility is a leading cause of accidents in industries such as mining. Furthermore, a study by the Institution of Engineers Australia found that improved lighting can reduce accidents by up to 60%.

Designing intrinsically safe lighting for dusty environments is a complex task that requires a deep understanding of both the environment and the principles of safe lighting design. By considering factors such as light intensity, beam angle, color temperature, and enclosure design, it is possible to create lighting solutions that enhance visibility and safety in even the most challenging conditions. At the Intrinsically Safe Store, we are committed to providing such solutions. Contact us today to learn more about our range of intrinsically safe products.