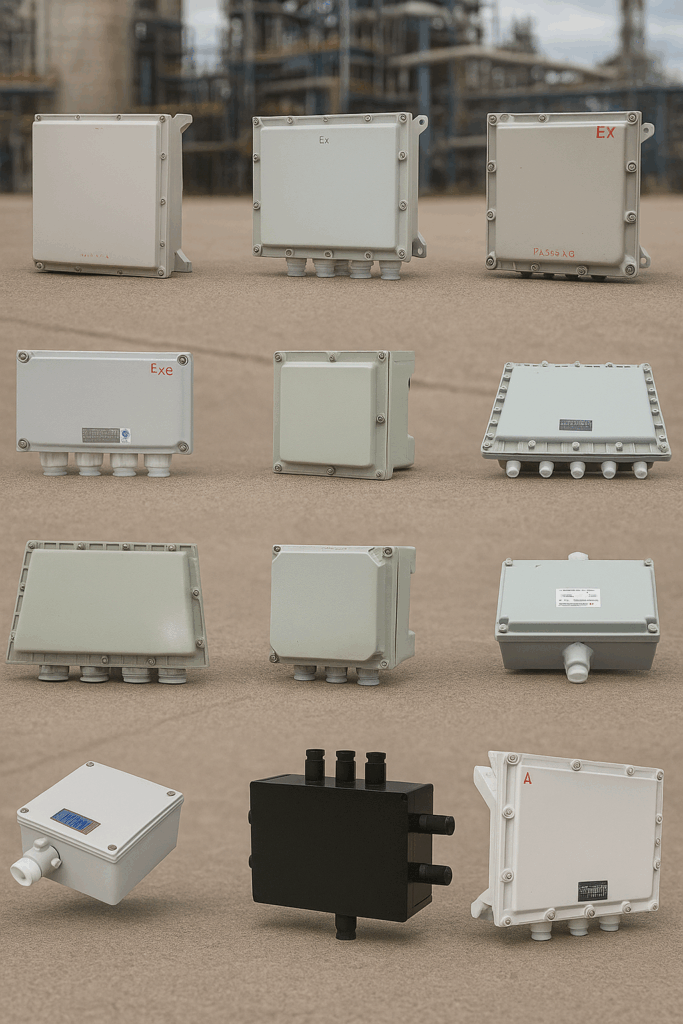

In hazardous locations where flammable gases, vapors, or dust are present, electrical safety is non-negotiable. Every connection, wire, and junction must be protected against ignition sources—and that’s where the explosion proof junction box comes in.

For electricians, engineers, and safety managers working in petrochemical plants, refineries, and manufacturing facilities, selecting the right explosion proof junction box ensures compliance, reliability, and peace of mind.

Need Certified Explosion-Proof Junction Boxes?

Get ATEX/IECEx options for hazardous locations. Fast quotes and expert guidance.

ATEX · IECEx · UL — Request a quote in minutes.In this guide, we’ll cover everything you need to know about these critical enclosures—including pricing, sizes, certifications, installation tips, and product comparisons available at Intrinsically Safe Store.

What Is an Explosion Proof Junction Box?

An explosion proof junction box is a sealed electrical enclosure designed to contain sparks or flames that may occur within the box, preventing them from igniting explosive gases or dust in the surrounding environment.

They are commonly made of aluminum, stainless steel, or heavy-duty cast metals, and are certified for use in hazardous areas (Zones 1, 2, 21, 22) under ATEX, IECEx, and UL standards.

Explosion-proof boxes are critical for safely housing:

Cable terminations and connections

Control circuits and sensors

Network and communication equipment

Power distribution junctions

Why Do Electricians and Engineers Need Explosion-Proof Junction Boxes?

For professionals working in hazardous environments, compliance and safety are top priorities. Explosion-proof junction boxes provide:

Ignition Containment: Prevent internal sparks from escaping.

Durability: Withstand extreme temperature, vibration, and corrosion.

Ease of Installation: Pre-threaded entries simplify wiring and reduce setup time.

Versatility: Support various conduit types and mounting configurations.

Compliance: Meet ATEX, IECEx, and UL1203 standards for classified zones.

These boxes not only protect your equipment—they protect your entire operation from catastrophic failure.

How Much Does an Explosion Proof Junction Box Cost?

Prices for explosion-proof junction boxes can vary widely depending on material, size, brand, and certification type.

Below is a price comparison of popular models available at Intrinsically Safe Store:

| Model | Brand | Material | Certifications | Approx. Price (USD) | Use Case |

|---|---|---|---|---|---|

| Explosion Proof Junction Box for Detect-A-Fire Units | Detect-A-Fire | Aluminum | ATEX, UL | $570.00 | Fire detection and temperature sensors |

| Kaixuan KX-EX08CBS44-A Explosion Proof Junction Box | Kaixuan | Cast Aluminum | IECEx, ATEX | $30.00 | Compact circuits and cable junctions |

| Kaixuan KX-EX10CBD Explosion Proof Junction Box | Kaixuan | Stainless Steel | IECEx, ATEX | $688.75 | Process control and automation |

| Spectrum EX-JB-H-POE-8-BD Explosion-Proof Junction Box | Spectrum | Aluminum Alloy | ATEX Zone 1/2 | $11,430.00 | POE and network integration in hazardous areas |

| Spectrum EX-JB-TB504-R Explosion-Proof Junction Box | Spectrum | Aluminum Alloy | ATEX, UL, CSA | $10,982.00 | Heavy-duty power or instrument distribution |

Best Choice by Application:

Compact, budget-friendly: Kaixuan KX-EX08CBS44-A

Process control and reliability: Kaixuan KX-EX10CBD

High-end industrial networking: Spectrum EX-JB-H-POE-8-BD

Fire detection systems: Detect-A-Fire Units model

Compare Models & Get a Quote

Not sure which box fits your zone, IP rating, or cable entries? We’ll help you size and certify the right enclosure.

Free guidance on conduit types, entries, and mounting.What Sizes Are Explosion-Proof Junction Boxes Available In?

Explosion-proof junction boxes come in a range of sizes and configurations, allowing electricians and engineers to choose the best fit for their installation.

| Size Category | Common Dimensions (inches) | Recommended Use |

|---|---|---|

| Small | 3″ x 3″ x 2″ | Sensors, compact circuits |

| Medium | 6″ x 6″ x 4″ | Cable terminations, small relays |

| Large | 12″ x 10″ x 8″ or larger | Control panels, POE and network systems |

Pro tip: Always leave at least 20% extra space for wire bending and maintenance access inside the box.

How to Choose the Right Explosion-Proof Junction Box?

When choosing an explosion proof junction box, consider these five key factors:

Certification Type

Make sure the box is certified for your hazardous zone (e.g., ATEX Zone 1, IECEx).Material

Aluminum is lightweight and corrosion-resistant; stainless steel offers superior durability.Ingress Protection (IP) Rating

Look for at least IP66 for outdoor or dusty environments.Mounting & Cable Entry

Verify compatibility with your conduit system (threaded or gland type).Operating Temperature Range

Confirm suitability for your site’s environmental conditions.

For electrical engineers, modular designs like the Kaixuan KX-EX10CBD simplify complex control system integration.

New to Classified Areas? Start with These Guides

Learn standards, zones, and device selection before you buy.How Do You Install an Explosion-Proof Junction Box?

Installation requires adherence to both manufacturer instructions and local electrical codes (such as NEC Article 500).

Step-by-Step Installation Guide:

De-energize the Circuit: Ensure the power source is completely off.

Mount the Box Securely: Use certified fasteners and ensure tight contact with mounting surfaces.

Thread the Conduit: Apply sealing compound if required for the zone classification.

Connect the Wires: Use approved terminal blocks and ensure tight mechanical connections.

Inspect Gasket Seals: Verify that covers and seals are intact and fully closed.

Perform a Leak Test: For high-risk zones, pressure testing may be required before commissioning.

Note: Improper installation can void certification and compromise explosion safety.

What Certifications Should You Look For?

Explosion-proof junction boxes must meet international standards that define their protection levels.

| Certification | Region | Meaning |

|---|---|---|

| ATEX | European Union | Suitable for explosive atmospheres (Directive 2014/34/EU) |

| IECEx | Global | International standard for electrical equipment in explosive atmospheres |

| UL 1203 / CSA | North America | Explosion-proof and dust-ignition-proof enclosures |

| IP Rating (IP66/IP68) | Global | Dust-tight and water-resistant protection level |

For example, Spectrum models like EX-JB-H-POE-8-BD meet ATEX Zone 1 standards, making them ideal for oil & gas or offshore applications.

What Are the Common Applications?

Explosion-proof junction boxes are used in nearly every industry where flammable materials are present:

Oil & Gas: Refineries, offshore platforms, gas pipelines

Chemical & Petrochemical Plants: Process control and monitoring circuits

Mining Operations: Power distribution in underground areas

Pharmaceutical Manufacturing: Dust-prone production areas

Food Processing Plants: Zones with combustible dust or flour particles

Engineers often integrate these boxes into broader intrinsically safe systems for maximum protection.

What Are the Benefits of Using Explosion-Proof Junction Boxes?

Safety

Prevents explosions caused by sparks, arcs, or high-temperature components.

Durability

Built with corrosion-resistant materials to handle outdoor and offshore environments.

Compliance

Ensures operations meet ATEX, IECEx, and OSHA safety requirements.

Reduced Downtime

Minimizes maintenance and risk of equipment failure.

Frequently Asked Questions (FAQs)

Are explosion-proof junction boxes waterproof?

Yes. Most are rated IP66 or higher, meaning they are dust-tight and resistant to powerful water jets or submersion, depending on model.

Can I use a regular junction box in a hazardous location?

No. Standard junction boxes cannot contain sparks or flames and pose serious explosion risks in classified areas.

Do explosion-proof junction boxes need maintenance?

Yes. Periodic inspections are required to ensure seals and threads remain intact. Replace gaskets and fasteners if damaged.

What’s the difference between “explosion proof” and “intrinsically safe”?

“Explosion proof” means the enclosure can contain an explosion; “intrinsically safe” means the circuit itself cannot produce enough energy to ignite an explosion.

Where can I buy explosion-proof junction boxes online?

You can find certified, industry-tested models at the Intrinsically Safe Store.

Ready to Specify Your Junction Box?

Talk to an expert or browse certified models now.

Expert guidance and fast delivery for hazardous locations.Conclusion: Reliable Safety for Every Connection

An explosion proof junction box is more than just a metal enclosure—it’s a critical safeguard for electrical systems in hazardous environments.

Whether you’re an engineer designing an offshore platform or an electrician upgrading a refinery circuit, choosing a certified and properly installed junction box ensures operational safety, compliance, and long-term durability.

Explore the complete selection of ATEX and IECEx certified explosion-proof junction boxes at the Intrinsically Safe Store—your trusted source for industrial safety solutions.