Explosion-proof motor starters play a critical role in industries where flammable gases, vapors, or combustible dusts may be present. These environments require electrical equipment designed to operate safely under fault conditions, ensuring sparks, arcs, or excessive heat never ignite the surrounding atmosphere. This guide explains what an explosion proof motor starter is, how to choose the right type, how certifications apply, how sizing works, and what installation requirements must be followed for compliance and safe operation.

Explosion-proof starters are mandatory in numerous industrial sectors, and proper selection directly impacts safety, operational reliability, and regulatory compliance. Understanding the principles behind protection concepts, enclosure ratings, and motor control methods is essential for any facility operating in hazardous areas.

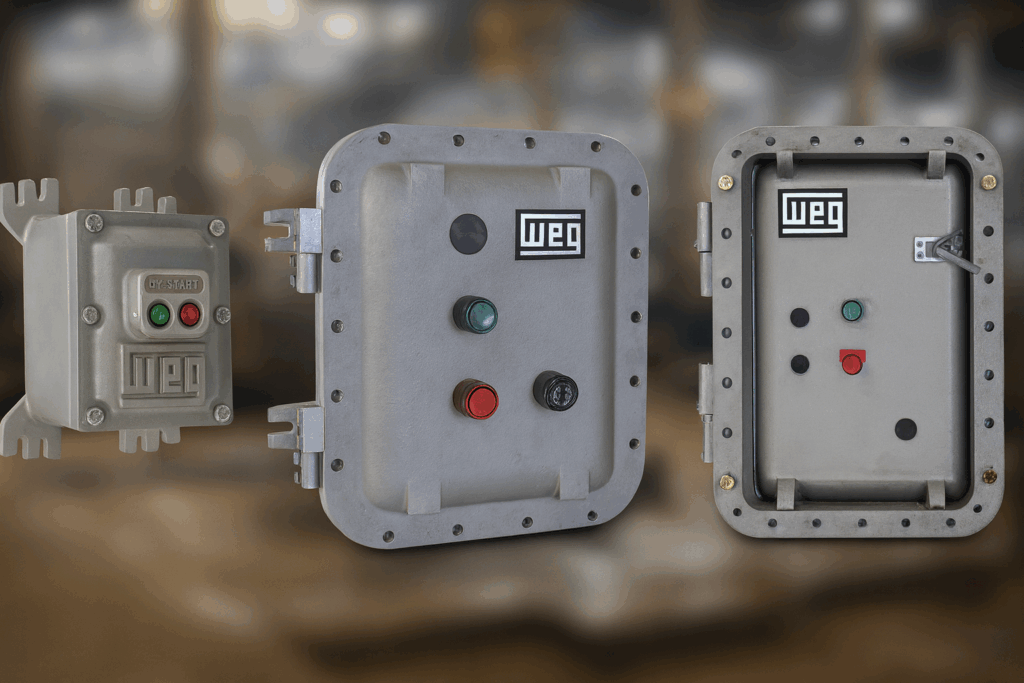

Motor starters in hazardous areas depend on the right enclosure strategy. Explore certified explosion-proof enclosures to support safe switching, heat control, and long-term compliance.

What Is an Explosion-Proof Motor Starter?

An explosion-proof motor starter is an electrical device used to start, stop, and protect motors in hazardous locations. These starters are housed inside flameproof enclosures designed to withstand internal ignition events. If a spark or arc occurs during switching, the enclosure contains the explosion and cools escaping gases so they cannot ignite the surrounding atmosphere.

Key Functions of Explosion-Proof Motor Starters

Start and stop motor circuits

Provide overload and short-circuit protection

Prevent ignition of hazardous atmospheres

Maintain safe operation during switching activities

House control components in a flameproof enclosure

Explosion-proof starters typically comply with ATEX, IECEx, UL, CSA, NEC, or CEC requirements depending on where they are used.

Why Explosion-Proof Starters Are Required in Hazardous Areas

In hazardous areas, electrical equipment must be designed to eliminate or contain ignition sources. Motor starters inherently produce arcs during operation. Without explosion-proof construction, these arcs could ignite gases, vapors, or dusts present in the environment.

Industries That Require Explosion-Proof Motor Starters

Oil and gas processing

Chemical and petrochemical plants

Grain handling and milling operations

Mining facilities

Pharmaceutical production

Fuel storage and distribution

Marine and offshore operations

Explosion-proof equipment ensures safe, continuous operation even under fault conditions.

Types of Explosion-Proof Motor Starters

What are the main types of explosion-proof motor starters?

Explosion-proof motor starters come in several configurations depending on motor size, load requirements, and application needs. These include Direct-On-Line (DOL) starters, Star-Delta starters, soft starters, and VFD-based systems. All types can be integrated into flameproof or pressurized enclosures suitable for hazardous areas.

Direct-On-Line (DOL) Starters

DOL starters apply full voltage directly to the motor, making them simple and robust. They are widely used for small and medium motor applications.

Advantages

Simple construction

Cost-effective

Reliable for general-purpose motors

Limitations

High inrush current

Not ideal for large motors requiring reduced starting torque

Star-Delta Starters

Star-delta starters reduce starting current by initially wiring the motor in a star configuration before switching to delta.

Advantages

Reduces electrical stress

Suitable for larger motors

Minimizes voltage dips

Limitations

Requires more internal components

More complex wiring inside the enclosure

Explosion-Proof Soft Starters

Soft starters gradually ramp up voltage, reducing mechanical and electrical stress.

Benefits

Smooth acceleration

Reduces impact on pumps, conveyors, and compressors

Minimizes heat shock and water hammer in piping systems

Explosion-Proof VFD Starters

Variable Frequency Drives control motor speed and torque. Because VFDs generate heat, they may require pressurized enclosures or safe-area installation with remote controls.

Best suited for:

Pumping systems

Compressors

Industrial fans

Variable-speed conveyors

Whether you’re evaluating DOL, star-delta, soft starters, or VFD-based systems, your motor selection and hazardous rating must align with the same safety and performance intent.

Hazardous Area Ratings and Certifications

What certifications should an explosion-proof motor starter have?

Explosion-proof starters must match the hazardous area’s classification. Certification ensures the equipment is tested and verified for operation under defined explosive atmospheres.

Common ATEX/IECEx Marking Example

Ex d IIB T6 Gb

Interpretation:

Ex d: Flameproof enclosure

IIB: Gas group

T6: Maximum surface temperature of 85°C

Gb: Suitable for Zone 1 environments

North American Classification Systems

Class I: Gas and vapor environments

Class II: Dust environments

Division 1: Hazard likely

Division 2: Hazard unlikely or intermittent

Groups A–G: Specific material classifications

How do ATEX Zones compare to NEC Divisions?

| ATEX Zone | Description | NEC Equivalent |

|---|---|---|

| Zone 0 | Continuous presence of explosive gas | Class I, Division 1 |

| Zone 1 | Likely presence during normal operation | Class I, Division 1 |

| Zone 2 | Unlikely or short-duration presence | Class I, Division 2 |

| Zone 20 | Continuous combustible dust | Class II, Division 1 |

| Zone 21 | Likely dust presence | Class II, Division 1 |

| Zone 22 | Occasional dust presence | Class II, Division 2 |

Understanding classifications ensures proper starter selection for safety and regulatory compliance.

If you’re validating classifications or comparing protection concepts, these guides will help you confirm the right path before specifying equipment.

Sizing an Explosion-Proof Motor Starter

How do you size an explosion-proof motor starter?

Correct sizing ensures reliable performance and avoids nuisance trips or overheating. Sizing depends on full-load current (FLA), operating voltage, duty cycle, enclosure type, and ambient temperature.

Essential Sizing Steps

Determine motor full-load current.

Select an overload relay adjustable to approximately 115% of FLA.

Ensure the short-circuit current rating matches system fault capacity.

Choose an enclosure large enough to dissipate heat.

Match the certification (Ex d, Ex p, Ex tb) to the area classification.

Explosion-proof enclosures restrict airflow, so proper thermal management is critical.

What environmental factors influence motor starter sizing?

Environmental conditions impact thermal rise, enclosure requirements, and component longevity. Key factors include:

High ambient temperature

Vibration or mechanical shock

Humidity and corrosive atmospheres

Dust accumulation

Outdoor exposure requiring IP66 or NEMA 4X protection

Thermal rise, enclosure volume, and derating considerations

Explosion-proof housings can trap heat, requiring derating of components or selecting larger enclosures. Proper sizing helps prevent premature failure and ensures safe continuous operation.

Installation Requirements for Explosion-Proof Motor Starters

What are the key installation rules in hazardous areas?

Installation must preserve the enclosure’s certification and maintain flameproof integrity. All components, fittings, and accessories must be certified for the hazardous area classification.

Cable entry and gland requirements

Only certified Ex d, Ex e, or Ex tb glands may be used

Adequate thread engagement must be ensured

Barrier glands required with flexible cables

Adapters and reducers must also be certified

Cable outer sheath must match environmental conditions

Conduit and sealing fittings

For NEC and CEC installations:

Seal-off fittings must be installed within required distances

Sealing compounds must fully fill the fitting

Rigid metal conduit is usually required

Bonding continuity must be maintained

Earthing and bonding

Proper grounding prevents static discharge and ensures safe fault clearing.

Requirements include:

External and internal grounding terminals must be used

Armored cable bonding continuity

Equipotential bonding for conductive structures

Temperature classification and mounting

Verify T-rating compatibility with ambient conditions

Maintain clearance from heat sources

Provide adequate space for air circulation

Ensure mounting surfaces can withstand enclosure weight

Ingress protection (IP/NEMA) considerations

IP66/IP67 or NEMA 4X for washdown or outdoor environments

Glands must preserve enclosure ingress rating

Corrosion-resistant materials may be required

Internal spacing and wiring layout

Maintain minimum creepage and clearance distances

Do not overcrowd internal components

Ensure wiring does not obstruct flame paths

Local vs. remote starter placement

Local starters suitable for Zone 1/Div 1 environments

Large motors may place starters in safe areas with remote controls

VFDs often require pressurized (Ex p) enclosures

Inspection and maintenance requirements

Explosion-proof motor starters must undergo periodic inspections per IEC 60079-17 and NFPA 70B, including:

Flame path condition

Tightening of bolts and cable glands

Gasket integrity

Corrosion and environmental damage

Label visibility and certification markings

Comparison Table: Explosion-Proof Motor Starter Types

| Feature / Type | Ex DOL Starter | Ex Star-Delta Starter | Ex Soft Starter |

|---|---|---|---|

| Certifications | ATEX/IECEx, Class I Div 1 | ATEX/IECEx | ATEX/IECEx (often Ex p) |

| Best For | Small–medium motors | Larger induction motors | Smooth acceleration needs |

| Starting Current | High | Moderate | Low |

| Complexity | Low | Medium | Medium–High |

| Heat Generation | Moderate | High | High |

| Common Applications | General industry | Water treatment, refining | Pumps, compressors |

Recommended Equipment Categories

Explosion-proof motor starter systems often incorporate:

Explosion-proof control stations

Flameproof enclosures

Explosion-proof disconnect switches

ATEX junction boxes and cable glands

These components support compliant, safe motor starter assemblies in hazardous areas.

Industry-Based Selection Guide

| Industry | Best Motor Starter Type | Reason |

|---|---|---|

| Oil and Gas | Ex d DOL or Star-Delta | High reliability and flameproof safety |

| Chemical Processing | Ex d Soft Starter | Smooth acceleration minimizes process impact |

| Mining | Heavy-duty Ex d DOL | Robustness against vibration and dust |

| Food and Grain | Ex tb Starter | Suitable for combustible dust environments |

| Water/Wastewater | VFD with Ex p | Ideal for pump speed control |

For a complete hazardous-area motor control assembly, these components often support compliant installations alongside starter systems.

FAQs About Explosion-Proof Motor Starters

Are explosion-proof starters the same as intrinsically safe equipment?

No. Intrinsically safe (IS) equipment limits electrical energy, while explosion-proof (Ex d) equipment contains ignition inside a flameproof enclosure. Motor starters require more energy than IS design permits.

Can a standard motor starter be used in a safe area with cables running into a hazardous area?

Yes, but only if all wiring methods, seals, and motor terminal equipment meet hazardous-area requirements. The starter itself must remain in a non-classified location.

Do explosion-proof motor starters need regular maintenance?

Yes. Flame paths, gaskets, torque values, and cable glands must be inspected periodically in accordance with IEC 60079-17 and NFPA 70B.

Can VFDs be certified explosion-proof?

VFDs generate significant heat and typically require Ex p pressurization or installation in a safe area with remote control interfaces.

Does the starter need the same gas group rating as the motor?

Yes. All equipment in the hazardous area must match or exceed the location’s gas or dust group classification.

Conclusion

Choosing the correct explosion proof motor starter is essential for ensuring safety, compliance, and operational reliability in hazardous environments. Understanding protection concepts, hazardous-area classifications, starter types, sizing methods, and installation rules enables organizations to design safer electrical systems and reduce ignition risks. With proper equipment selection and adherence to installation standards, explosion-proof motor starters provide long-term protection and dependable performance in challenging industrial environments.