Feeling intrinsically confused? 🙂 It is easy to feel overwhelmed by all the different certifications and safety equipment definitions. Our team at the Intrinsically Safe Store is to not only provide you all the latest and greatest Intrinsically Safe products but provide you with the confidence you need to keep your team safe, meeting the required certification and operations running smooth.

Intrinsic Definition

Intrinsic definition by Oxford Dictionary defines Intrinsic as “being an extremely important and basic characteristic of a person or thing.” The word Intrinsic is the root word of how to define Intrinsically Safe. The key part of the Oxford Intrinsic definition is the “basic characteristic” or as we like to think the “base” or “insides” of the thing. For our purposes, think the insides or components making up the overall electrical product.

What does Intrinsically Safe mean?

Simply put, Intrinsically Safe means a protection method or standard for electrical equipment used in hazardous areas.

What are Hazardous Areas?

Hazardous areas, Hazardous locations (or sometimes referred Hazloc) are areas that a fire or explosion could exist. Sources of ignition could include flammable gases, flammable liquid, flammable vapor, combustible dust, and combustible fibers.

What are Hazardous Area Classifications?

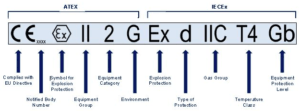

Hazardous Areas have a variety of different characteristics such as gas, dust or temperatures which are then classified into different ratings. Depending on where you are located will determine what classification safety body you should follow. The European Union typically falls under ATEX with a CE Mark or a North American Intertek, CSA, UL or similar Nationally Recognized Testing Laboratory

Hazardous area classification chart

We have a variety of different Hazardous area classification charts depending on the ignition sources and certification body.

What is ATEX? ATEX Directive and ATEX certification?

ATEX originally French (ATmosphères EXplosibles), is a European (EU) directive to help guide what equipment can be used in hazardous areas with explosive atmospheres. More here

ATEX rating

While there are a number of different ATEX ratings the most common are ATEX Zone 2 (lowest risk), ATEX Zone 1 and ATEX Zone 0 (Highest risk). Most of the products at Intrinsically Safe Store are Zone 2 & 1 as this is the most common in industrial use.

*It is important to confirm with your operational standards that the products are fit for purpose.*

ATEX Zone 2

ATEX Zone 2 is an area where an explosive atmosphere consisting of a mixture with air of dangerous substances such as gas, vapor or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

ATEX Zone 1

ATEX Zone 1 is an area where an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapor or mist is likely to occur in normal operation occasionally.

ATEX Zone 0

ATEX Zone 0 is an area where an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapor or mist is present continuously or for long periods or frequently

ATEX Zone 22

ATEX Zone 22 is an area where an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

ATEX Zone 21

ATEX Zone 21 is an area where an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally.

ATEX Zone 20

ATEX Zone 20 is an area where an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously, or for long periods or frequently.

What is Explosion Proof?

A product capable of withstanding an internal explosion and containing the original explosion ignition to prevent ignition of any surrounding flammable gas or material. There are a number of different certification bodies including the National Fire Protection Association (NFPA) which publishes the NEC (National Electic Code).

Intrinsically Safe vs. Explosion Proof?

Read more about Intrinsically Safe vs. Explosion Proof here. Basically, they are different designs for protecting a Hazardous areas. Explosion proof contains the risk inside a robust housing and the design of Intrinsically Safe products are to remove the risk of an explosion from happening. Depending on your project needs, risk level, installation resources, and budget will determine what solution is the best match for the lowest risk outcome.

What is IECEx?

IECEx – International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres is a system to facilitate international trade in equipment and services for use in explosive atmospheres while maintaining the required level of safety:

What is Class 1 Div 2

Class 1 div 2 is defined as one of the following three situations:

- An environment that contains or handling with volatile flammable liquids or flammable gases. Normally those hazardous materials are kept in closed containers or closed systems from which they can escape only in the event of accidental rupture or breakdown of such containers or systems, or as a result of abnormal operation of equipment.

- Ignitable concentrations of gases or vapors can be prevented by positive mechanical ventilation, and which might become hazardous through failure or abnormal operations of the ventilating equipment.

- Adjacent to a Class I, Division 1 location, and to which ignitable concentrations of gases or vapors might occasionally be communicated unless such communication is prevented by adequate positive-pressure ventilation from a source of clean air, and effective safeguards against ventilation failure are provided.

What is an Intrinsic Barriers?

Intrinsic Barrier, IS Barrier or Electric Barrier as sometimes they are called is a device for electrical equipment that could run the risk of a surge. The surge could result in an ignition source igniting external hazards such as flammable gas or dust. Think of Intrinsic Barriers as a pressure valve for electrical equipment in hazardous locations.

What is non incendive?

A non-incendive or non-incendive circuit is where any arc or thermal effect produced under intended operating conditions of the equipment is not capable of igniting a hazardous area source (flammable gas, liquid, dust, etc.) An additional non-incendive article can be found here.

Non incendive vs intrinsically safe

The ATEX or any other Intrinsically Safe certification requires that the product won’t create an ignition source. Also, it is necessary to test the product for a specific fault condition. Otherwise, the non-incendive product doesn’t need to pass this specific test.