In high-risk industries like oil and gas, mining, chemical manufacturing, and food processing, electrical equipment used in hazardous environments must meet strict safety standards. That’s where intrinsically safe power tools come in.

Designed to prevent ignition in explosive atmospheres, intrinsically safe (IS) tools are engineered to eliminate sparks, arcs, or high temperatures that could cause fires or explosions. Whether your operations are in a Class I Division 1 or Zone 0 area, these tools help ensure compliance, worker safety, and uninterrupted productivity.

Explore our full guide to intrinsically safe tools by industry to make the safest choice for your operation.

What Are Intrinsically Safe Power Tools?

Intrinsically safe power tools are built to prevent ignition of flammable gases, vapors, or dust in hazardous locations. Unlike standard tools, IS tools restrict the energy available for ignition and often use pneumatic or specially sealed electric designs.

They meet stringent certifications like:

ATEX (Europe)

IECEx (International)

UL and CSA (North America)

The tools are typically labeled with information like:Ex ib IIC T4 Gb, indicating the protection level, gas group, temperature class, and zone.

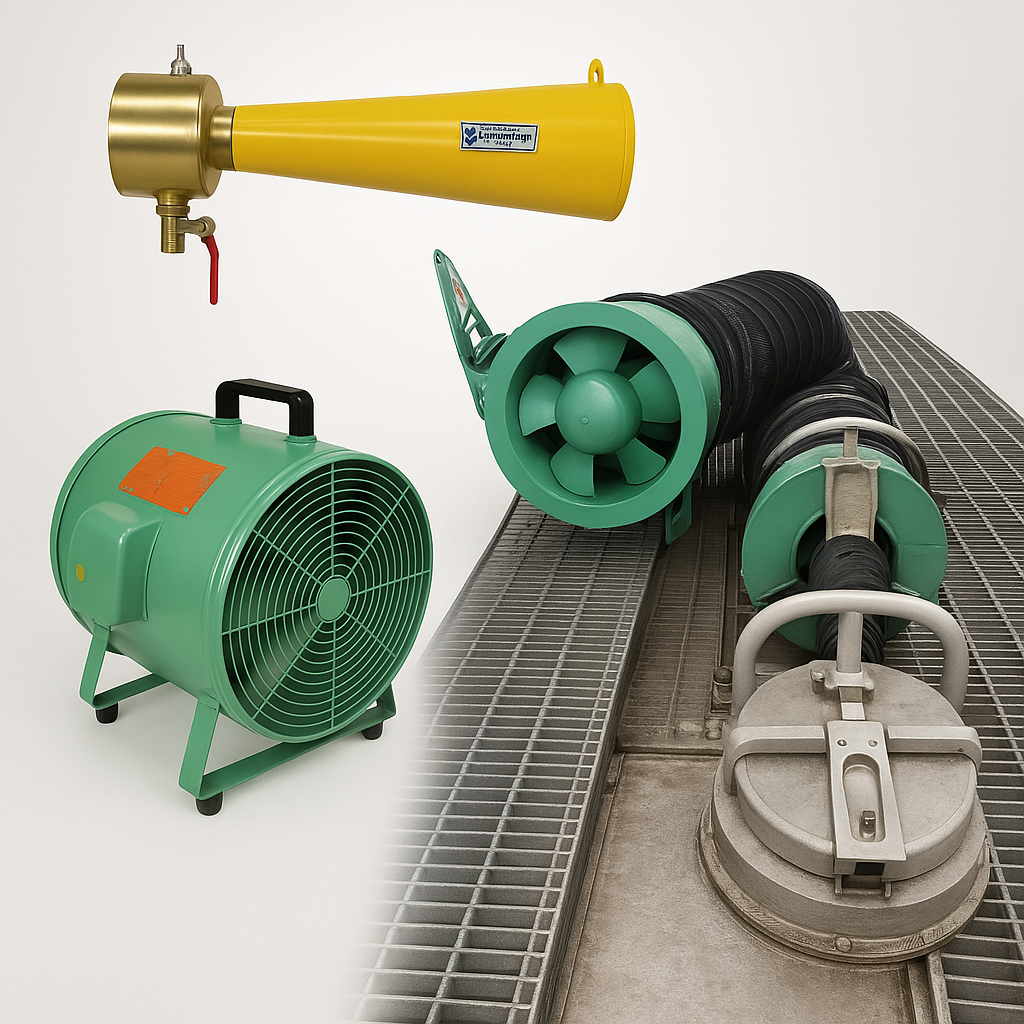

What Are the Most Common Intrinsically Safe Power Tools?

The following types of intrinsically safe tools are staples in hazardous locations:

Intrinsically Safe Flashlights and Headlamps

Used for inspections in confined spaces, tanks, tunnels, and rigs.Intrinsically Safe Communication Devices

Like radios and mobile phones, for safe real-time communication.Non-Sparking Hand Tools

Including wrenches, hammers, and pliers made of brass or beryllium copper.Battery Packs and Chargers

Certified battery modules used in explosion-proof mobile devices.Intrinsically Safe Cameras and Tablets

Used for digital inspections, reporting, and asset tracking.

How Do Intrinsically Safe Power Tools Differ from Standard Tools?

| Feature | Intrinsically Safe Power Tools | Standard Power Tools |

|---|

| Safety Rating | Certified for use in hazardous/explosive environments | Not certified for explosive or flammable areas |

| Certifications | ATEX, IECEx, UL, CSA | General consumer or industrial certifications |

| Design Considerations | Spark-proof, sealed components, reduced heat output | Conventional design with no explosion protection |

| Usage Environment | Oil rigs, chemical plants, refineries, grain silos | Construction sites, workshops, home use |

| Power Source Isolation | Designed to prevent electrical arcs/sparks | May generate sparks during operation |

| Materials Used | Anti-static, corrosion-resistant, non-sparking metals | Standard metals and plastics |

| Maintenance Requirements | Requires certified inspection and regular safety checks | Standard maintenance procedures |

| Cost Range | $1,000–$4,000+ depending on tool and certification | $50–$1,000 depending on brand and use case |

| Regulatory Compliance | Mandatory in classified hazardous zones (Class I, Div 1) | Not compliant with hazardous area regulations |

| Best For | Safety-critical environments with ignition risks | General-purpose, non-hazardous environments |

Still unsure which tool fits your needs?

Talk to an expert and find the right tool for your hazardous zone

Where Are Intrinsically Safe Tools Used Most Often?

1. Oil & Gas

For pipeline maintenance, tank inspections, flare stack work, and remote communication.

2. Chemical Plants

Used around volatile organic compounds and solvent vapors.

3. Mining

Deep tunnels often contain combustible gases like methane.

4. Pharmaceutical Manufacturing

Combustible dust and alcohol-based compounds require IS-rated tools.

5. Food Processing

Dust from powdered ingredients or sprays can create ignition hazards.

Top Intrinsically Safe Power Tools You Can Buy Today

Below is a selection of certified tools available at Intrinsically Safe Store:

| Product | Certifications | Features | Use Cases |

|---|

| Shenzhen Hazardous Location CES-EX-LN-02-40-60 LED Lights | Not specified | Explosion-proof LED lighting | Hazardous location illumination |

| Kaixuan KX-EX600PW Explosion Proof CCTV Camera Enclosure | Not specified | Explosion-proof camera housing | Monitoring in explosive environments |

| Xciel iPhone 11 Case ATEX Zone 2 Rated | ATEX Zone 2 | Intrinsically safe smartphone case | Using iPhone 11 in hazardous areas |

| Xciel iPhone 14 ATEX Zone 2 | ATEX Zone 2 | Intrinsically safe smartphone case | Using iPhone 14 in hazardous areas |

| Xciel iPhone 12 Case | Not specified | Intrinsically safe smartphone case | Using iPhone 12 in hazardous areas |

Best Choice by Industry:

Oil & Gas: Ecom Ex-Handy 10 DZ1

Mining: Nightstick XPP-5422GMX

Field Service: IS530.1 Smartphone

Process Control: CorDex EXIS Pack

Documentation: Extronics iCAM502

How to Choose the Right Intrinsically Safe Tool

Match Your Zone or Class Rating

Tools are rated for:

Zone 0, 1, or 2 (EU/IECEx)

Class I/II Division 1/2 (North America)

Verify Certification Labels

Check for relevant markings like:

“Ex ib IIC T4 Gb” or

“Class I, Div 1, Groups A-D, T4”

Match the Tool to the Task

Use task-specific tools like:

Flashlights for inspection

Communication for mobile work

Cameras/tablets for digital workflows

Prioritize Reliability

Choose durable, IP-rated tools that withstand dust, vibration, and temperature swings.

How to Maintain Intrinsically Safe Tools

Maintenance is critical to compliance and safety. Here’s how to do it right:

Routine Visual Checks: Look for casing cracks, corrosion, or wear.

Battery Safety: Only use approved chargers; never modify.

Keep Certifications Updated: Replace expired labels or re-certify if necessary.

Store Tools Properly: Dry, sealed cases away from harsh environments.

Employee Training: Make sure all personnel understand use limitations.

FAQs About Intrinsically Safe Power Tools

What does “intrinsically safe” actually mean?

It means the tool can’t release enough energy, even under fault conditions, to ignite flammable substances in the environment.

Are battery-powered tools ever intrinsically safe?

Yes — but only if they are certified. Tools like the IS530.1 smartphone and EXIS740 battery pack are safe when used as directed.

Can I use IS tools in Zone 0 areas?

Only tools explicitly certified for Zone 0 can be used in continuous-risk environments.

What industries are required to use IS tools?

Any facility that falls under OSHA hazardous location standards (NFPA 70/NEC) or ATEX Zone classifications must use them.

Can standard tools be made intrinsically safe?

No. Tools must be built and certified as IS from the start; modifying standard tools voids safety integrity.

Conclusion

If you’re operating in a hazardous environment, intrinsically safe power tools are not optional—they’re essential. Whether you’re performing maintenance in a chemical plant, inspecting pipelines on a rig, or documenting conditions underground, using certified tools ensures safety, compliance, and peace of mind.

Visit Intrinsically Safe Store to explore the full range of certified tools, smart devices, and accessories tailored for hazardous zones. Our experts can guide you to the safest and most effective equipment for your specific application.