Vibration monitoring has become one of the most powerful tools in predictive maintenance—especially in industries where rotating machinery operates in hazardous areas. An intrinsically safe vibration sensor enables maintenance teams to capture accurate, real-time condition data without risking ignition in explosive atmospheres. When used correctly, these sensors reduce unplanned downtime, extend equipment life, and improve worker safety.

This comprehensive guide explains how intrinsically safe vibration sensors work, why they’re essential in hazardous locations, the different sensor types, selection criteria, certifications, and industry applications. You’ll also find product comparisons and recommendations from IntrinsicallySafeStore.com to help you choose the right device for your operation.

What Is an Intrinsically Safe Vibration Sensor?

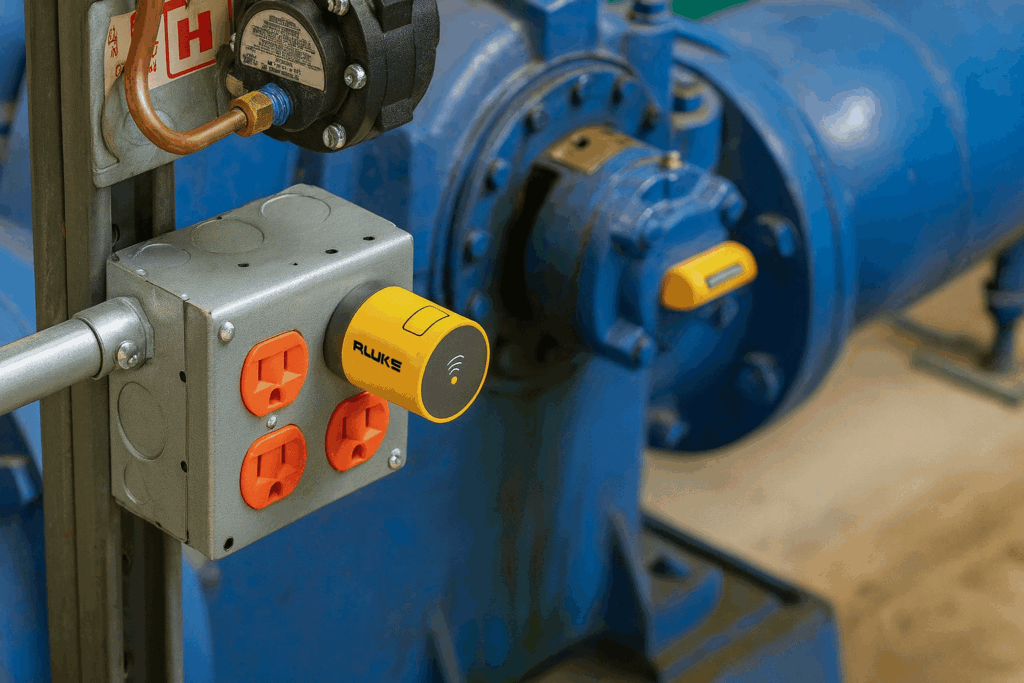

An intrinsically safe vibration sensor is a vibration-measuring device engineered to operate safely in explosive atmospheres by limiting electrical and thermal energy to non-ignition levels. These sensors are essential for monitoring rotating equipment such as motors, pumps, compressors, and turbines located in hazardous zones.

By providing continuous or periodic vibration data, they help detect early signs of mechanical failure before breakdowns occur.

Ready to deploy intrinsically safe vibration monitoring in your plant?

Explore certified vibration sensors and measurement solutions designed for hazardous areas.

Why Vibration Monitoring Matters

Industry data shows that over 50% of rotating equipment failures originate from mechanical faults, many of which exhibit warning signs through changes in vibration levels. Predictive maintenance supported by vibration sensing can reduce unplanned downtime by 30–50% and extend equipment life by 20–40%, according to multiple reliability engineering studies.

How Does an Intrinsically Safe Vibration Sensor Work?

An intrinsically safe vibration sensor measures acceleration, velocity, or displacement caused by machine movement. It translates mechanical vibration into an electrical signal that can be analyzed manually or through condition monitoring software.

The key difference is the internal design: intrinsically safe sensors use protected circuitry, energy-limiting components, and certified barriers to prevent sparking, heat buildup, or ignition in hazardous spaces.

Main Functional Components

Sensing element: typically piezoelectric, MEMS, or electrodynamic

Signal conditioning electronics: convert raw motion into usable data

Intrinsically safe circuitry: limits voltage, current, and stored energy

Encapsulation: prevents propagation of heat or sparks

Explosion-proof housing (depending on type): durable mechanical protection

Why Do Hazardous Areas Require Intrinsically Safe Vibration Sensors?

Hazardous locations typically contain flammable gases, vapors, mists, dusts, or fibers that can ignite from sparks or hot surfaces. Because traditional vibration sensors use electrical components, they require engineering controls to prevent ignition.

An intrinsically safe vibration sensor eliminates the risk by ensuring the sensor can never release enough energy to ignite an explosive mixture.

Industries Requiring Intrinsic Safety

Oil & gas

Chemical processing

Pharmaceuticals

Mining

Food & beverage (dust hazards)

Water treatment

Power generation

Marine and offshore

These environments typically fall under ATEX, IECEx, CSA, or UL hazardous location classifications.

What Certifications Apply to Intrinsically Safe Vibration Sensors?

Certifications confirm that a vibration sensor is safe for operation in explosive atmospheres. Requirements vary by region, but most sensors must meet at least one of the following:

Major Certifications

ATEX (EU): Explosive Atmosphere Equipment Certification

IECEx (International): Harmonized global safety standard

UL/CSA (North America): Class I, II, III Divisions

UKCA Ex (UK): Post-Brexit hazardous location standard

Need clarity on hazardous area certifications?

Deepen your understanding of ATEX, IECEx and Class I Division 1/2 requirements before you choose your sensors.

How to Read Certification Labels

For example:

ATEX II 1G Ex ia IIC T4 Ga

Each part explains category, protection concept, gas group, and temperature class.

Intrinsically Safe vs. Explosion-Proof

Intrinsically Safe (IS): Limits energy, best for portable or low-power sensors

Explosion-Proof (XP): Contains an internal explosion, typically for fixed installations

What Types of Intrinsically Safe Vibration Sensors Are Available?

Different applications require different sensor technologies. Below are the most common types used in hazardous environments.

1. Piezoelectric Accelerometers (Most Common)

These sensors detect acceleration forces and are highly accurate for high-frequency vibration.

Best for: rotating machinery, pumps, fans, compressors.

2. MEMS Vibration Sensors

Micro-electromechanical systems with digital output options.

Best for: battery-powered wireless sensors, IoT systems, low-frequency detection.

3. Velocity Sensors

Measure vibration velocity rather than acceleration—useful for medium-frequency machinery.

Best for: general-purpose condition monitoring.

4. Displacement Sensors

Capture shaft vibration or position changes.

Best for: turbines, high-speed motors.

How Do You Choose the Right Intrinsically Safe Vibration Sensor?

Selecting the right sensor depends on machine type, measurement range, environmental hazards, and collection method.

Here are the main factors to consider:

Measurement Factors

Frequency range (e.g., 2 Hz–10 kHz)

Sensitivity (mV/g or digital resolution)

Measurement type (acceleration, velocity, displacement)

Dynamic range

Environmental Requirements

ATEX/IECEx/UL certifications

Ingress protection (IP67–IP69)

Chemical resistance

Operating temperature

Data Collection Method

Permanent (wired) installation

Portable, handheld data collection

Wireless IoT systems

Turn vibration data into real maintenance decisions.

Pair your intrinsically safe sensors with certified tablets, phones and cameras for field inspections and data collection.

What Are the Advantages of Using Intrinsically Safe Vibration Sensors?

Intrinsically safe vibration sensors deliver essential benefits for hazardous industries:

Key Advantages

Improved safety with energy-limiting circuitry

High-quality vibration data for better predictive maintenance

Reduced maintenance costs via early failure detection

Greater uptime & reliability for mission-critical assets

Regulatory compliance for ATEX, IECEx, UL/CSA environments

Flexible installation for permanent or portable monitoring

Which Intrinsically Safe Vibration Sensors Are Recommended?

Below are popular intrinsically safe vibration monitoring solutions available at IntrinsicallySafeStore.com.

Comparison Table: Intrinsically Safe Vibration Sensors

| Product | Certs | Features | Use Cases | Type |

|---|---|---|---|---|

| RAW Intrinsically Safe Vibration Sensor | ATEX, IECEx | Wireless, long battery life, hazardous location certified | Pumps, motors, compressors | Wireless accel. |

| Hansford Sensors ATEX Accelerometers (HS-150 Series) | ATEX, IECEx | High-frequency piezo accelerometer, rugged stainless steel housing | Fans, blowers, rotating equipment | Wired accel. |

| CTC Hazardous Area Accelerometers | ATEX, UL | Industrial-grade velocity and acceleration sensing | Petrochemical, drilling, refining | Wired accel. |

| MMX Wireless Vibration Sensor (IS Version) | ATEX | Wireless IoT vibration + temperature | Remote monitoring, predictive maintenance | Wireless MEMS |

Best Choice by Use Case

General rotating equipment: Hansford Sensors HS-150

Wireless predictive maintenance: RAW IS Vibration Sensor

High-frequency applications: CTC Hazardous Area Accelerometers

IoT cloud systems: MMX Wireless IS Sensor

How Do Intrinsically Safe Vibration Sensors Support Predictive Maintenance?

These sensors detect early-stage mechanical problems that would otherwise go unnoticed. They provide actionable data that engineers can analyze to identify failure modes such as:

Common Faults Detectable by Vibration

Imbalance

Misalignment

Bearing wear

Gear mesh problems

Cavitation

Resonance

Structural looseness

By collecting real-time vibration data, maintenance teams can schedule repairs before failures occur, reducing downtime and extending asset life.

Want to build a full predictive maintenance strategy?

Learn how intrinsically safe and explosion-proof equipment fit into a long-term reliability program in hazardous areas.

How Is Data Collected Safely in Hazardous Areas?

Data collection in hazardous zones must follow strict safety protocols. An intrinsically safe vibration sensor ensures that the measurement point itself poses no ignition risk.

Safe Collection Methods

Portable intrinsically safe analyzers

Hardwired IS sensors connected to safe-area instrumentation

Wireless vibration nodes transmitting to a gateway outside the hazardous zone

Barriers or isolators are often required when connecting IS sensors to external equipment.

What Installation Considerations Apply to IS Vibration Sensors?

Several factors influence installation effectiveness and safety:

Key Considerations

Mount sensors using studs rather than adhesive whenever possible

Ensure grounding and shielding to minimize noise

Use approved cable glands and connectors

Follow zone classification rules for ATEX/IECEx/UL

Verify maximum cable lengths for intrinsic safety compliance

What Industries Benefit Most from Intrinsically Safe Vibration Sensors?

Any industry with hazardous areas and rotating machinery can benefit from predictive vibration monitoring. Below are the most common.

Oil & Gas

Covers upstream drilling, midstream pipelines, and downstream refining. Equipment such as pumps and compressors must be monitored continuously.

Chemical & Petrochemical

High-risk atmospheres make intrinsic safety mandatory for nearly all instrumentation.

Food & Beverage

Dust hazards in milling, sugar processing, and grain handling require non-sparking equipment.

Pharmaceuticals

Solvents used in manufacturing create potentially explosive environments.

Mining

Methane pockets and coal dust elevate explosion risks, requiring IS sensors for fans, conveyors, and crushers.

Need help selecting intrinsically safe vibration sensors for your facility?

Talk to our hazardous-area experts to specify the right sensors, enclosures and field devices for your predictive maintenance program.

Prefer to equip your team on site? Don’t forget intrinsically safe flashlights for inspections in dark or confined spaces: view intrinsically safe flashlights .

FAQs About Intrinsically Safe Vibration Sensors

What does “intrinsically safe” mean for a vibration sensor?

It means the sensor is designed to prevent ignition by limiting electrical and thermal energy. These devices are engineered for use in hazardous areas with flammable gases or dusts.

Can a standard vibration sensor be used in a hazardous environment?

No. Standard sensors pose ignition risks and are not certified for explosive environments. Only intrinsically safe or explosion-proof sensors are permitted.

Do intrinsically safe sensors require special wiring?

Yes. Most installations require approved IS wiring, glands, and barriers to ensure the entire measurement loop meets intrinsic safety standards.

What types of machinery need intrinsically safe vibration monitoring?

Common examples include pumps, fans, motors, compressors, blowers, and turbines operating in hazardous zones.

Are wireless intrinsically safe vibration sensors reliable?

Yes. Modern IS wireless sensors provide high-quality vibration and temperature data, long battery life, and robust connectivity suitable for predictive maintenance.

Conclusion: Why an Intrinsically Safe Vibration Sensor Is Essential

An intrinsically safe vibration sensor is a critical tool for predictive maintenance in hazardous environments. By delivering safe, accurate, and continuous vibration data, these sensors help organizations reduce downtime, extend asset life, and enhance worker safety. Whether your operation uses pumps, compressors, conveyors, or turbines, IS sensors ensure compliance and reliability while preventing ignition in explosive atmospheres.