Welcome to Intrinsically Safe Store, your one-stop-shop for all your safety equipment needs. We are dedicated to providing you with the most reliable and up-to-date information on safety standards. In this article, we will be comparing three major hazardous area standards: NEC, IEC, and ATEX. We invite you to visit our website for more information and to explore our wide range of safety products.

Understanding Hazardous Area Standards

Hazardous area standards are guidelines set by various organizations to ensure safety in environments where there is a risk of explosion or fire due to the presence of flammable gases, vapors, or dust. These standards are crucial in industries such as oil and gas, mining, and chemical processing. They provide a framework for classifying hazardous areas, selecting appropriate equipment, and implementing safety procedures.

NEC (National Electrical Code)

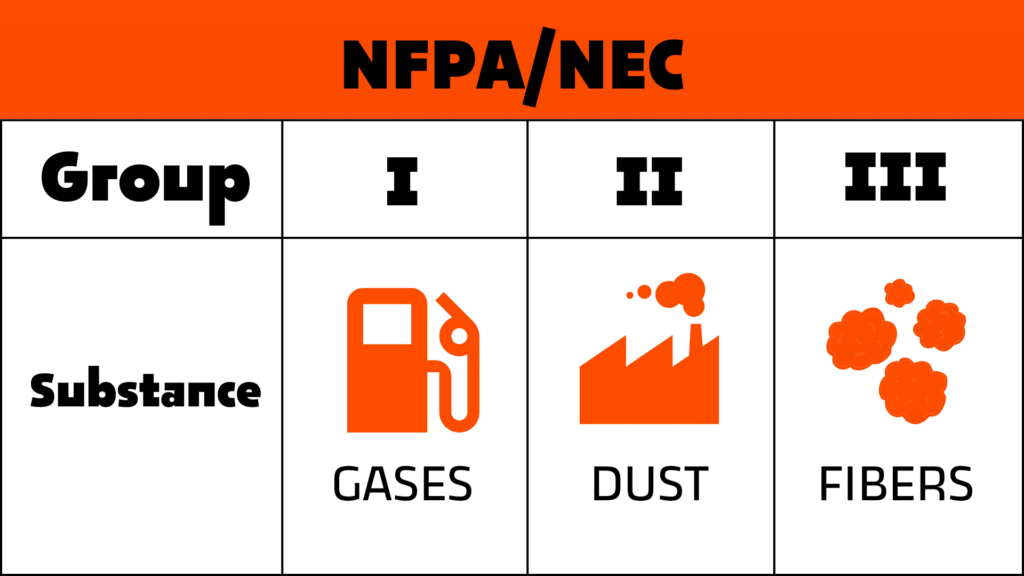

The NEC, also known as NFPA 70, is a standard used primarily in the United States. It provides guidelines for the safe installation of electrical equipment in hazardous areas. The NEC classifies hazardous areas into Classes, Divisions, and Groups based on the nature and degree of the hazard.

Key Features of NEC

- Classifies hazardous areas into Class I (Gases), Class II (Dust), and Class III (Fibers and Flyings).

- Further divides each class into Division 1 (normal operation) and Division 2 (abnormal operation).

- Groups hazardous materials based on their explosive characteristics.

IEC (International Electrotechnical Commission)

The IEC is an international standard that is widely accepted around the world. It uses a different approach to classify hazardous areas, focusing on Zones rather than Divisions.

Key Features of IEC

- Classifies hazardous areas into Zones 0, 1, and 2 for gases, and Zones 20, 21, and 22 for dust.

- Defines equipment protection levels (EPL) to indicate the level of protection provided by equipment.

- Uses a system of Equipment Protection Levels (EPLs) to indicate the level of protection that equipment provides.

ATEX (Atmosphères Explosibles)

ATEX is a European standard that applies to all equipment intended for use in explosive atmospheres. It requires manufacturers to provide a declaration of conformity for their products, indicating that they meet the necessary safety requirements.

Key Features of ATEX

- Classifies hazardous areas into Zones, similar to the IEC.

- Requires equipment to be marked with the ‘EX’ symbol to indicate compliance.

- Includes requirements for both equipment and protective systems.

Comparing NEC, IEC, and ATEX

While all three standards aim to ensure safety in hazardous areas, they differ in their approach and scope. The NEC focuses on the installation of electrical equipment, while the IEC and ATEX cover a broader range of equipment and protective systems. The IEC and ATEX use a zone system for classification, which provides a more detailed analysis of the risk level. However, the NEC’s division system is simpler and easier to understand.

Understanding and complying with hazardous area standards is crucial for ensuring safety in industries that deal with flammable and explosive materials. While the NEC, IEC, and ATEX have their differences, they all provide valuable guidelines for classifying hazardous areas and selecting appropriate equipment. At Intrinsically Safe Store, we commit ourselves to help you navigate these standards and find the right safety solutions for your needs. Visit our website to learn more or contact us for personalized assistance.