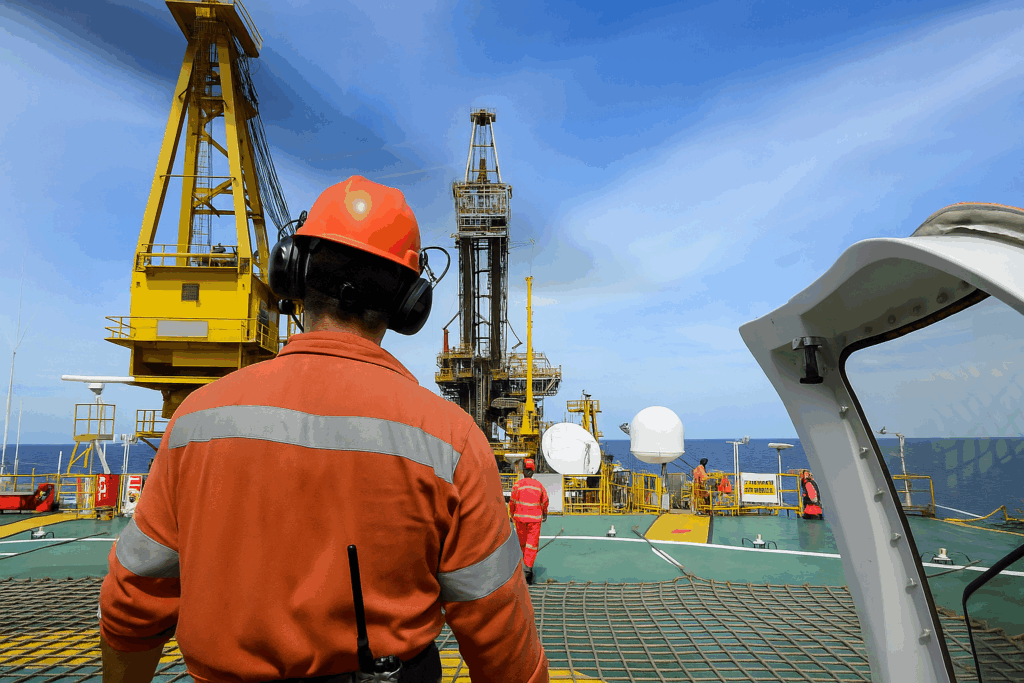

In today’s high-risk industrial environments, wireless communication is no longer a luxury—it’s a lifeline. Workers in oil & gas, chemical plants, mining, and manufacturing rely on ATEX certified headsets to ensure constant, clear, and safe communication without compromising safety. These headsets combine intrinsically safe technology with wireless mobility, allowing workers to stay connected in explosive atmospheres (Zones 0, 1, or 2) where even a single spark could lead to disaster.

Explore Certified Headsets for Every Industry

Browse our range of ATEX Certified Headsets and Intrinsically Safe Radios designed for hazardous zones.

ATEX (Atmosphères Explosibles) certification ensures that a device is built to operate safely in explosive atmospheres, and when paired with modern Bluetooth® or two-way radio systems, these headsets deliver both protection and performance.

What Does “ATEX Certified Headset” Mean?

An ATEX certified headset is designed to prevent ignition in environments that contain flammable gases, vapors, or dust. The certification confirms that the headset meets strict European Union safety standards for equipment used in hazardous zones.

Key Points:

ATEX Directive 2014/34/EU governs the design and manufacturing of such equipment.

Certification ensures the headset won’t produce sparks, arcs, or heat that could ignite explosive atmospheres.

Common classifications include Zone 0, Zone 1, and Zone 2 (for gas) and Zone 20, 21, and 22 (for dust).

In essence, if your operation is located in an ATEX-rated zone, you need communication devices that are equally certified to operate there safely.

Why Choose a Wireless ATEX Headset for Industrial Communication?

1. Freedom of Movement

Wireless headsets eliminate tangled cords and allow operators to move freely across large work areas. This is crucial for maintenance technicians, supervisors, and machine operators who need both mobility and communication reliability.

2. Enhanced Safety and Awareness

Many ATEX headsets, such as those from Sensear, integrate SENS® technology to enhance situational awareness—allowing users to hear environmental sounds while still being protected from harmful noise levels.

3. Compatibility and Connectivity

Modern ATEX headsets feature Bluetooth®, two-way radio, and wired connection options, supporting a wide range of radio systems including Motorola, Kenwood, and Hytera.

4. Noise Reduction for Harsh Environments

These headsets often achieve Noise Reduction Ratings (NRR) up to 27 dB, maintaining communication clarity even in environments exceeding 95 dBA noise exposure.

Top ATEX Certified Wireless Headsets for Industrial Use

Below is a detailed comparison of some of the leading ATEX headsets available at Intrinsically Safe Store. Each headset provides reliable communication solutions designed for hazardous industrial applications.

| Model | Certification | Connectivity | Noise Reduction | Hazardous Rating | Price (USD) | Best For |

|---|---|---|---|---|---|---|

| Sensear SM1P02 Ex Two Way Radio Headset | ATEX, IECEx | Two-Way Radio, Bluetooth | Up to 27 dB NRR | Zone 1 | $1,362.24 | Oil & Gas, Mining |

| Sensear SM1PBEXDP02 Two Way Radio Headset | ATEX, IECEx | Bluetooth, Face-to-Face, Two-Way | Up to 27 dB NRR | Zone 1 | $1,566.33 | Heavy Manufacturing |

| Sensear SM1P02 IS Two Way Radio Headset | ATEX, IECEx | Bluetooth | Up to 27 dB NRR | Zone 1 | $1,147.96 | Utilities, Power Plants |

| Ecom SM1P Series HB Bluetooth® Headset | ATEX Zone 1, IECEx | Bluetooth® | Up to 27 dB NRR | Class 1 Division 1 | $1,200.00 | Field Communication |

| Ecom SM1P Series HM Bluetooth® Headset | ATEX Zone 1, IECEx | Bluetooth® | Up to 27 dB NRR | Class 1 Division 1 | $1,200.00 | Construction, Industrial Safety |

Need Help Choosing the Right Headset?

Talk to our experts to find the best ATEX or IECEx certified headset for your worksite. Learn more about ATEX vs IECEx standards or get a free consultation below.

Best Choice by Industry

Oil & Gas Operations: Sensear SM1P02 Ex Two Way Radio Headset – designed for extreme noise and flammable gas zones.

Manufacturing & Refining: Sensear SM1PBEXDP02 – provides dual protection and seamless Bluetooth integration.

Utilities & Maintenance: Sensear SM1P02 IS – lightweight, dependable, and affordable.

Construction & Field Work: Ecom SM1P HM Series – ergonomic with Bluetooth® communication for mobility.

Hazardous Inspection Teams: Ecom SM1P HB Series – certified for Class I, Division 1 environments.

How Do ATEX Headsets Ensure Safety in Explosive Atmospheres?

ATEX headsets undergo rigorous testing to guarantee they don’t act as ignition sources. Each component—from battery housings to microphones—is designed for low energy output and controlled surface temperature.

Protective Design Features

Intrinsically Safe Circuits: Limit electrical and thermal energy.

Anti-Static Materials: Prevent charge accumulation.

Encapsulated Components: Isolate potential ignition sources.

Temperature Control: Prevents surfaces from reaching ignition temperatures.

These combined safety mechanisms make ATEX headsets ideal for use in petrochemical plants, offshore platforms, refineries, and grain processing facilities.

Which ATEX Rating Do You Need for Your Worksite?

ATEX Zones Explained

| Zone | Presence of Explosive Atmosphere | Typical Use Case |

|---|---|---|

| Zone 0 | Constant or long-term presence | Inside fuel tanks or pipelines |

| Zone 1 | Likely during normal operations | Refineries, chemical mixing areas |

| Zone 2 | Unlikely, but possible | Storage facilities, loading bays |

Most industrial headsets are certified for Zone 1, meaning they’re safe for operations where explosive gases or vapors are expected under normal working conditions.

What’s the Difference Between ATEX and IECEx Certification?

Both ATEX and IECEx certify equipment for explosive atmospheres, but they apply in different regulatory regions.

| Aspect | ATEX | IECEx |

|---|---|---|

| Region | European Union | Global (including Australia, Middle East, Asia) |

| Standard | EU Directive 2014/34/EU | IEC 60079 series |

| Focus | Legal compliance for EU markets | Technical equivalence globally |

| Marking | Ex II 2G | Ex ib IIC T4 Gb |

Products with dual certification (ATEX + IECEx), such as Sensear and Ecom models, provide international compatibility—ideal for multinational corporations.

How Does Bluetooth Technology Work Safely in ATEX Headsets?

Bluetooth modules in intrinsically safe headsets are energy-limited and shielded. They communicate using low-energy radio signals that meet ATEX temperature and spark safety thresholds.

These headsets maintain:

Reliable wireless range (up to 50 meters)

Low-latency audio

Automatic pairing with compatible radios

Fail-safe cutoff mechanisms in case of malfunction

That means workers can talk freely and hands-free, even while operating machinery or inspecting pipelines, without risk of ignition.

Frequently Asked Questions (FAQs)

1. Are all wireless headsets ATEX certified?

No. Only models specifically designed and tested under the ATEX Directive are approved for use in explosive environments. Regular wireless headsets can pose ignition risks due to uncontrolled energy discharge.

2. Can Bluetooth devices be used in hazardous areas?

Yes—if the device is ATEX or IECEx certified. Certified Bluetooth modules meet low-power specifications and safety standards that prevent sparking.

3. What industries require ATEX headsets?

Common industries include oil & gas, chemical processing, mining, manufacturing, aviation fueling, and grain storage.

4. How do I know if my site requires ATEX-rated equipment?

Check your facility’s Hazardous Area Classification. If it includes Zone 0, 1, or 2 (gas) or Zone 20, 21, 22 (dust), you must use certified equipment.

5. How do ATEX headsets compare with non-ATEX models in audio quality?

Top manufacturers like Sensear and Ecom maintain crystal-clear digital audio, noise suppression, and advanced SENS® technology—equal or superior to non-rated counterparts.

Key Benefits of ATEX Certified Wireless Headsets

Explosion Protection: Certified for hazardous zones.

Wireless Mobility: Bluetooth® and two-way radio compatibility.

Hearing Safety: Built-in noise reduction (up to 27 dB NRR).

Durability: Industrial-grade materials and reinforced components.

Versatility: Supports multiple communication modes—radio, face-to-face, and intercom.

These advantages translate directly into greater worker efficiency, reduced downtime, and compliance with international safety regulations.

Ready to Upgrade Your Team’s Safety?

Equip your workers with intrinsically safe two-way radios and ATEX headsets for reliable communication in hazardous environments.

Choosing the Right ATEX Headset: A Buyer’s Guide

When selecting a certified wireless headset, consider:

Certification Requirements: Zone 1 or Class 1 Division 1.

Communication Needs: Bluetooth, two-way, or both.

Noise Level of Workplace: Choose high NRR models for 90+ dBA.

Comfort & Ergonomics: Adjustable headbands and padded ear cups.

Integration: Ensure compatibility with your existing radio system.

For example:

The Sensear SM1P02 Ex is ideal for refinery teams.

The Ecom SM1P Series HM is preferred for field inspections and construction.

The SM1PBEXDP02 fits high-noise manufacturing environments.

Conclusion: Enhancing Industrial Safety with ATEX Wireless Headsets

Investing in an ATEX certified headset means investing in the safety and efficiency of your workforce. These headsets empower teams to communicate clearly and wirelessly while meeting the strictest international safety standards for explosive environments.

Whether you’re managing an offshore platform, a refinery, or a manufacturing line, the right ATEX headset helps you stay connected without compromise.