Intrinsically safe temperature sensors play a critical role in hazardous-area operations where flammable gases, vapors, or dusts can turn a standard measurement device into an ignition source. Industries such as oil & gas, chemical production, refining, and manufacturing rely on sensors that are specifically engineered to operate safely in ATEX/IECEx certified environments.

In this guide, we break down everything you need to know about choosing the right intrinsically safe temperature sensor, including certifications, pricing, industrial use cases, and which models best support demanding hazardous-area applications.

Shop Intrinsically Safe Temperature Sensors

Browse certified ATEX/IECEx temperature and humidity sensors designed for hazardous industrial environments.

🔶 View Intrinsically Safe SensorsWhat Is an Intrinsically Safe Temperature Sensor?

An intrinsically safe temperature sensor is a measurement device designed to monitor temperature in hazardous environments without creating sparks, heat, or electrical energy capable of causing ignition. Rather than relying on heavy explosion-proof housings, intrinsically safe (IS) sensors limit energy at the circuit level so the device cannot ignite flammable atmospheres.

These sensors are widely used in:

Process manufacturing

Petrochemical plants

Oil & gas upstream and downstream operations

Pharmaceutical production

Grain handling and food processing

Hazardous storage and confined spaces

Their low-energy design and ATEX/IECEx certifications make them ideal for Zone 0, Zone 1, Zone 2, and Class I Division 1 (with appropriate barriers).

Explore Measurement & Calibration Tools

Find certified measurement devices engineered for hazardous-area process safety.

Browse Measurement Devices

How Do Intrinsically Safe Temperature Sensors Work?

Intrinsically safe temperature sensors operate on the principle of energy limitation. Electrical energy entering the device is restricted through:

Zener barriers

Galvanic isolators

Energy-limiting circuits

Even if the device fails, shorts, or is exposed to abnormal conditions, its circuitry cannot release enough heat or electrical energy to ignite a hazardous atmosphere.

Most IS temperature sensors use:

RTD elements (Pt100 or Pt1000)

Thermistors

Thermocouple inputs

Integrated digital temperature + humidity modules

A leading example is the E+E Elektronik EE100Ex, an ATEX Zone 1 certified humidity/temperature sensor designed for hazardous industrial applications. This model uses energy-limited circuits and supports intrinsically safe power sources or Zener barriers.

What Certifications Are Required for an Intrinsically Safe Temperature Sensor?

Certification is one of the most important aspects when selecting an intrinsically safe sensor. Below are the major global certifications and what they mean.

ATEX Certification

ATEX is the European directive governing equipment used in explosive atmospheres. Temperature sensors typically fall under:

ATEX Zone 0 – Continuous presence of explosive atmosphere

ATEX Zone 1 – Likely presence during normal operation

ATEX Zone 2 – Presence only in abnormal situations

The E+E Elektronik EE100Ex featured on Intrinsically Safe Store is ATEX Zone 1 certified, meaning it is approved for locations where hazardous vapors or gases may be present during normal operating conditions.

IECEx Certification

IECEx is an international certification system harmonized with ATEX. IECEx requirements validate:

Design safety

Ignition testing

Energy limitation

Compliance with Ex standards

The EE100Ex is also IECEx certified, making it suitable for global industrial deployments including South America, the Middle East, and Asia-Pacific markets.

Temperature Class Ratings

Temperature class (T-rating) identifies the maximum surface temperature of a device. Hazardous-area gases each have an ignition temperature; the device surface must stay well below that threshold.

Typical ratings include:

T6 – max 85°C

T5 – max 100°C

T4 – max 135°C

Intrinsic safety ensures the device never exceeds safe thermal limits—even during failure.

Understand Hazardous Location Safety Standards

Strengthen your knowledge with our essential guides on ATEX, IECEx, Class/Division ratings and intrinsically safe design.

What Applications Require an Intrinsically Safe Temperature Sensor?

Industries that contain flammable gases, vapors, or combustible dust rely on temperature sensors to monitor safety, process stability, and environmental conditions. Here are the most common applications.

Oil & Gas Operations

Temperature monitoring is essential in upstream, midstream, and downstream processes:

Tank farms

Wellheads

Gas compressors

Pump stations

Refinery units

LNG storage

Sensors like the EE100Ex allow measurement in areas where explosive atmospheres may form.

Process Manufacturing

Temperature affects chemical reactions, batch consistency, and safety. IS sensors are required in:

Chemical reactors

Mixing areas

Solvent-based processes

Flammable storage rooms

Maintaining precise measurement prevents runaway reactions and ensures process reliability.

Pharmaceutical & Biotech

Cleanrooms that handle volatile solvents rely on certified sensors to safely control:

Temperature

Humidity

Dew point

Frost point

A multi-variable sensor like the EE100Ex provides accurate readings for GMP and ISO-classified areas.

Food & Grain Processing

Combustible dust creates explosion hazards in:

Milling

Mixing

Packaging

Silos

Intrinsically safe sensors ensure dust does not ignite during routine monitoring.

Browse Power & Energy Solutions

Certified panels, distribution equipment, and power solutions for hazardous-area operations.

Shop Power & EnergyFeatured Product: E+E Elektronik EE100Ex Intrinsically Safe Humidity/Temperature Sensor

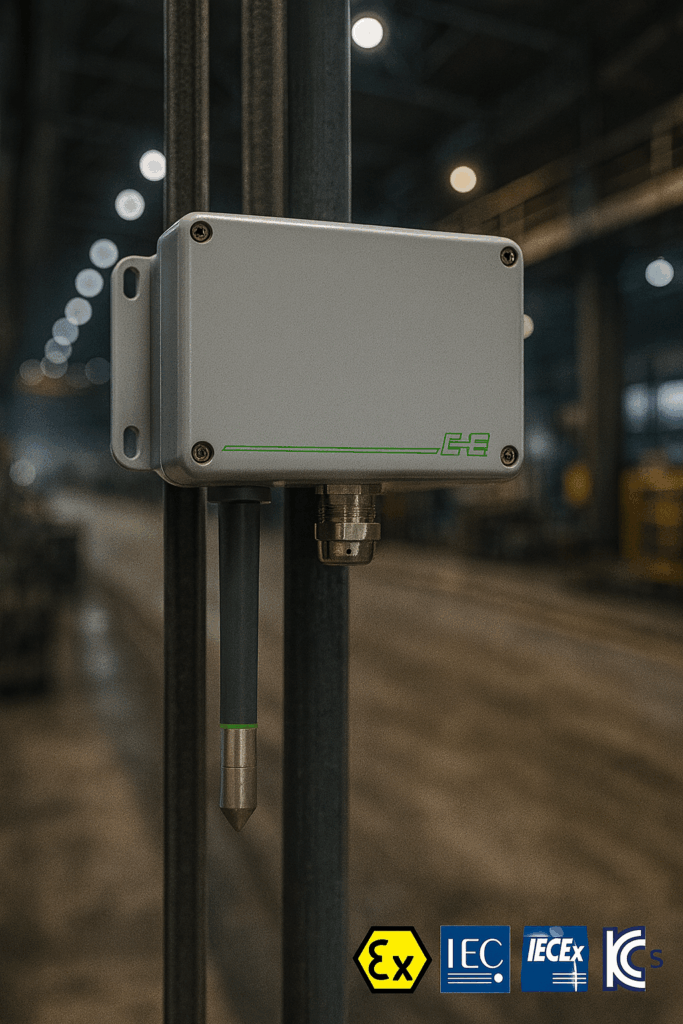

The screenshot provided shows the E+E Elektronik EE100Ex, a flagship ATEX/IECEx temperature and humidity sensor used widely in hazardous and industrial markets.

Key Features

ATEX Zone 1 certified

IECEx certified

Measures relative humidity and temperature

Dew point (Td) and frost point (Tf) calculations

Suitable for intrinsically safe power or Zener barrier systems

IP65 enclosure

Durable sensing head for harsh industrial environments

Best For

Oil & gas

Chemical plants

Hazardous manufacturing

Petrochemical storage

Pharmaceutical production

Pricing

Based on the product page:

$2,610.77 USD (subject to change depending on configurations and region availability).

How Much Does an Intrinsically Safe Temperature Sensor Cost?

Pricing varies depending on certification, sensing technology, and environmental protection levels. Below is a general breakdown for hazardous-area temperature sensors.

Typical Price Ranges

| Sensor Type | Price Range | Notes |

|---|---|---|

| Basic IS temperature probe | $800–$1,500 | RTD/thermocouple, simple housing |

| Humidity + temperature sensor (IS) | $1,600–$3,000 | ATEX/IECEx, multi-variable sensing |

| Advanced industrial sensor | $2,500–$5,000 | Specialized process applications |

| EE100Ex (featured) | $2,610.77 | ATEX Zone 1 / IECEx, humidity + temperature |

What Affects Pricing?

Key factors influencing cost:

Hazardous area certification (ATEX, IECEx)

Sensor type (RTD vs digital module)

Measurement accuracy requirements

Housing materials (aluminum, stainless steel, polymer)

Environmental protection (IP65–IP67)

Additional measurement capability (humidity, dew point, frost point)

High-end IS sensors often combine temperature, humidity, and dew-point sensing in one certified system—reducing installation costs but increasing product price.

How to Choose the Right Intrinsically Safe Temperature Sensor

Choosing the right sensor depends on process requirements and environmental conditions.

Determine the Hazardous Zone

Zone 0: Continuous hazard

Zone 1: Likely hazard (EE100Ex qualifies)

Zone 2: Occasional hazard

Always start with the hazardous classification of the installation area.

Choose the Correct Measurement Parameters

Do you need:

Temperature only?

Temperature + humidity?

Dew point/frost point?

Digital or analog output?

For multi-parameter industrial applications, a device like the EE100Ex provides more value.

Check Environmental Ratings

Key enclosure ratings:

IP65/IP66 – washdown, dust protection

Corrosion-resistant housings

Temperature operating ranges

Comparison Table: Intrinsically Safe Temperature Sensor Options

Below is a comparison of general sensor types including the EE100Ex.

| Feature | Basic IS Temperature Probe | IS Digital Temp Sensor | EE100Ex Humidity/Temp Sensor |

|---|---|---|---|

| ATEX/IECEx | Yes | Yes | Yes (Zone 1) |

| Measurement | Temperature | Temperature | Temp + RH + Td + Tf |

| Ideal For | Simple monitoring | Industrial control | Hazardous industrial environments |

| Enclosure | Stainless/Aluminum | Polymer/Metal | IP65-rated housing |

| Typical Price | $800–$1,500 | $1,200–$2,000 | $2,610.77 |

Need Help Selecting the Right Sensor?

Talk to our hazardous-area experts for guidance on ATEX/IECEx ratings, temperature ranges, and industrial requirements.

FAQs About Intrinsically Safe Temperature Sensors

Are intrinsically safe sensors the same as explosion-proof sensors?

No. Intrinsically safe sensors limit electrical energy to prevent ignition, while explosion-proof sensors contain explosions inside a housing. IS sensors are typically lighter and easier to install.

Can intrinsically safe temperature sensors be installed in Zone 1?

Yes. Many IS sensors—including the EE100Ex—are specifically certified for ATEX Zone 1 and IECEx environments.

Do I need a Zener barrier with an intrinsically safe sensor?

In most cases, yes. A Zener barrier or galvanic isolator ensures energy entering the sensor stays within safe limits.

Can these sensors measure dew point or frost point?

Some models, including the EE100Ex, calculate dew point (Td) and frost point (Tf) in addition to humidity and temperature.

Are intrinsically safe sensors suitable for outdoor use?

Yes, provided they have appropriate IP ratings. The EE100Ex is IP65, suitable for many outdoor and industrial environments.

Conclusion: Choosing the Best Intrinsically Safe Temperature Sensor

Selecting the right intrinsically safe temperature sensor depends on certification requirements, application conditions, and measurement needs. ATEX/IECEx sensors like the E+E Elektronik EE100Ex offer globally recognized safety approval, advanced multi-parameter measurement, and rugged construction for oil & gas, process manufacturing, chemical plants, and hazardous industrial sites.

For hazardous-area temperature and humidity monitoring solutions, browse the certified options available at Intrinsically Safe Store.