Pressure monitoring in hazardous industrial zones is a critical part of ensuring both operational efficiency and workplace safety. When flammable gases, vapors, or combustible dusts are present, traditional electrical instruments pose an ignition risk. To mitigate this risk, industries rely on the intrinsically safe pressure transmitter, a specialized device engineered to operate with extremely low energy levels that cannot ignite explosive atmospheres.

This article explores how intrinsically safe pressure transmitters work, their certifications, key features, accuracy benchmarks, and industrial applications. You’ll also learn how to select the right transmitter for your facility and find certified solutions available at Intrinsically Safe Store.

What Is an Intrinsically Safe Pressure Transmitter?

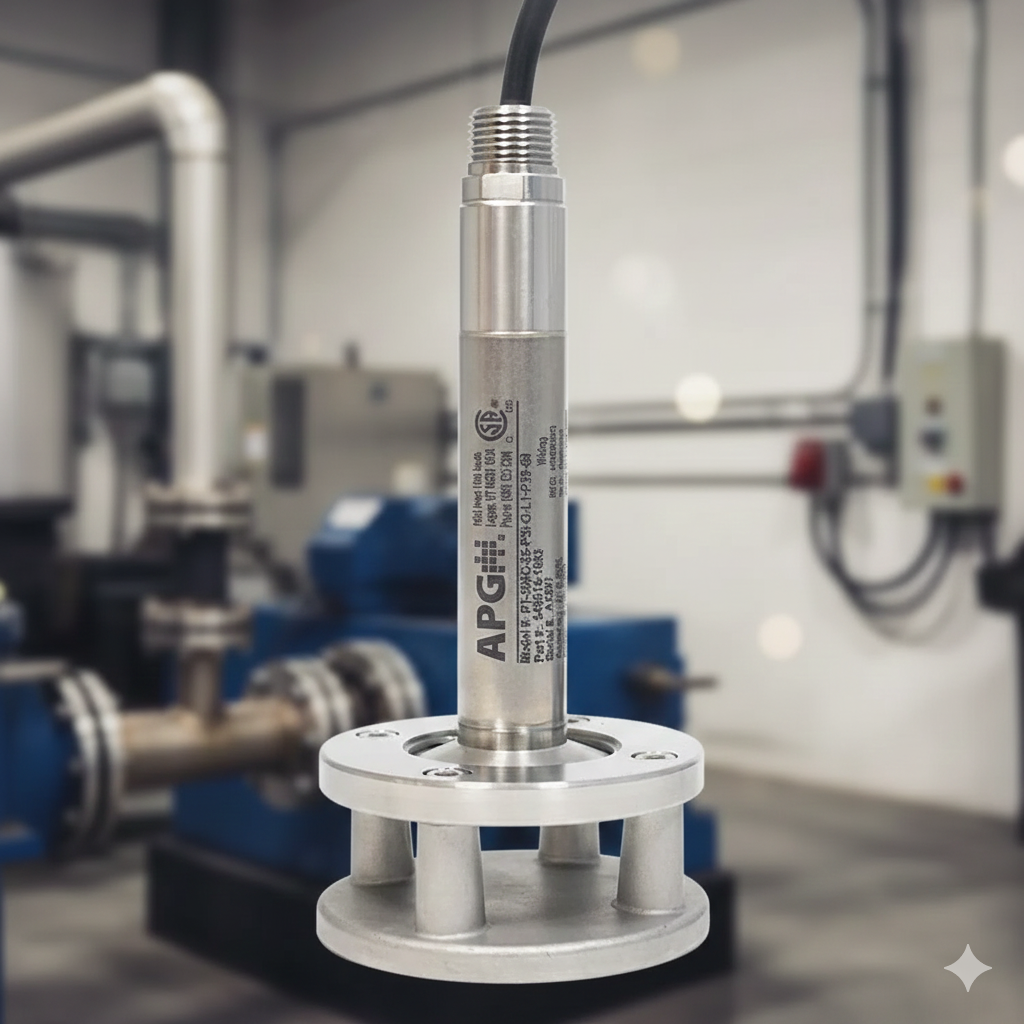

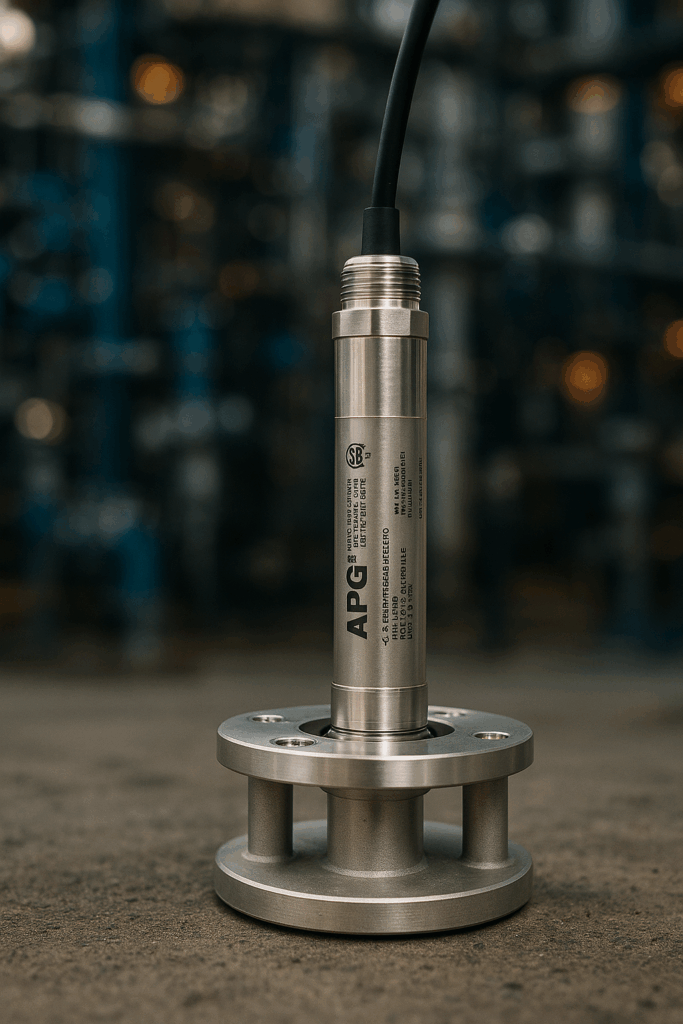

An intrinsically safe pressure transmitter is a pressure-sensing device designed to be safe for use in hazardous environments by limiting electrical and thermal energy below ignition thresholds. These instruments convert applied pressure into a usable electrical signal (such as 4–20 mA) while complying with ATEX, IECEx, UL, or CSA safety standards.

Intrinsically safe devices are particularly valuable in environments where flammable gases, vapors, or dusts could ignite due to sparking or overheating equipment.

How Intrinsically Safe Pressure Transmitters Work

Intrinsically safe pressure transmitters work by using a sensor element—often piezoresistive, capacitive, or strain gauge-based—that detects changes in pressure and outputs a proportional low-energy signal. Their internal circuits are engineered to prevent any spark or heat from exceeding ignition thresholds.

Measurement Process

Pressure applied to the diaphragm causes deformation.

Sensor electronics interpret the deformation as electrical changes.

The transmitter outputs a low-power 4–20 mA or digital signal.

Intrinsically safe barriers or isolators maintain compliance by limiting voltage and current.

This design ensures that even under fault conditions, the transmitter cannot generate enough energy to ignite a hazardous atmosphere.

Ready to choose an intrinsically safe pressure transmitter for your hazardous area?

Browse ATEX/IECEx-certified pressure transmitters and request a quote for your project.

View Intrinsically Safe Pressure TransmittersCertifications Required for Intrinsically Safe Pressure Transmitters

Pressure transmitters used in hazardous locations must meet strict global certification requirements. The certification needed depends on the region and type of hazardous environment.

Major Certification Standards

| Certification | Region | Purpose | Hazard Zones |

|---|---|---|---|

| ATEX | Europe | Ensures equipment safety in explosive atmospheres | Zone 0/1/2, 20/21/22 |

| IECEx | Global | International standard for hazardous area equipment | Zones 0–2, 20–22 |

| UL (Class/Div) | USA | North American hazardous locations | Class I/II, Div 1/2 |

| CSA | Canada | Canadian hazardous location standard | Class I/II, Div 1/2 |

| FM | USA | Verification for industrial explosive atmospheres | Class I/II, Div 1/2 |

Each certification evaluates factors such as maximum surface temperature, electrical energy limits, enclosure strength, and failure safety.

Unsure which certification your pressure transmitter needs?

Learn when to choose ATEX vs IECEx and how certification impacts device selection and compliance.

Read ATEX vs IECEx Certification GuideKey Features of an Intrinsically Safe Pressure Transmitter

Intrinsically safe pressure transmitters include safety-focused and performance-enhancing features that make them suitable for precision industrial applications.

Core Features

Energy-limited circuitry that prevents ignition under all conditions.

Temperature compensation for stable performance despite thermal fluctuations.

Strong ingress protection (IP65–IP68) for dust, moisture, and washdown environments.

Corrosion-resistant materials like stainless steel, titanium, or Hastelloy for harsh chemicals.

Long-term stability ensuring consistent accuracy over many years of service.

4–20 mA output commonly used in hazardous area control loops.

Compliance with ATEX, IECEx, UL, or CSA certifications for global usability.

These features make IS transmitters ideal for operations requiring precise monitoring under strict safety regulations.

Accuracy of Intrinsically Safe Pressure Transmitters

Accuracy is a critical factor in selecting the right pressure transmitter. Modern intrinsically safe transmitters offer accuracy levels competitive with high-performance industrial sensors.

Industry Benchmark Accuracy Values

| Performance Metric | Typical Value |

|---|---|

| Static accuracy | ±0.1–0.5% of full scale |

| Temperature coefficient | ±0.01–0.03% FS/°C |

| Long-term drift | ±0.1–0.2% per year |

| Response time | Less than 10 ms |

| Overpressure limit | Up to 2× rated pressure |

Accuracy is influenced by sensor type, environmental conditions, installation method, and long-term stability of the diaphragm and electronics.

Industrial Applications of Intrinsically Safe Pressure Transmitters

As industries adopt more automation, pressure transmitters become essential for monitoring and controlling production processes in hazardous zones.

Industries That Rely on IS Pressure Transmitters

Oil and gas

Petrochemical production

Chemical processing

Wastewater treatment

Mining and minerals

Pharmaceuticals

Food and beverage processing (dust hazards)

Common Use Applications

Pipeline pressure monitoring

Compressor discharge pressure

Tank level measurement using hydrostatic pressure

Pump protection

Steam system pressure control

Gas flow monitoring through differential pressure

In all these applications, intrinsic safety allows for reliable, continuous monitoring without risking ignition.

Product Comparison: Intrinsically Safe Pressure Monitoring Solutions

Below are pressure-sensing solutions and IS-compatible modules available through Intrinsically Safe Store. Some products serve as condition-monitoring devices rather than dedicated transmitters but can support hazardous-area pressure measurement capabilities.

Comparison Table

| Product | Certifications | Pressure Capability | Output | Key Features |

|---|---|---|---|---|

| Ecom AIRIS Vibration & Pressure Detection Sensor | ATEX, IECEx | Multi-sensor pressure capability | Wireless | Condition monitoring, IIoT-ready |

| Ecom AIRIS Module for Hazardous Areas | ATEX, IECEx | Integrates with pressure sensors | Wireless | Industrial sensor integration |

| Pepperl+Fuchs Intrinsically Safe Barriers | ATEX, IECEx, UL | Required for pressure transmitter loops | – | Ensures energy-limited circuits |

These components enable safe pressure monitoring workflows in complex hazardous environments.

Best Choice by Industry or Application

| Application | Recommended Type |

|---|---|

| Oil & Gas upstream | ATEX/IECEx transmitter with stainless steel diaphragm |

| Chemical production | Hastelloy or titanium wetted parts |

| Food & beverage | Hygienic, flush diaphragm |

| Wastewater | IP68-rated submersible pressure sensor |

| Mining | Shock-resistant, CSA/IECEx-rated |

| Tank monitoring | Differential or hydrostatic IS transmitters |

This ensures optimal performance and longer equipment life.

What Should You Look for When Selecting an Intrinsically Safe Pressure Transmitter?

Choosing the right transmitter requires evaluating pressure requirements, hazardous zone classification, environmental conditions, and wiring infrastructure.

Hazardous Area Classification

Check the zone or Class/Div compatibility:

ATEX Zone 0, 1, 2

IECEx Ex ia or Ex ib

Class I Div 1 or Div 2

Pressure Type and Range

Determine the correct measurement type:

Gauge

Absolute

Differential

Select a range with 20–50% overhead capacity above your maximum expected pressure.

Wetted Materials

Match the diaphragm and housing to your media:

Stainless steel: general-purpose

Hastelloy: aggressive chemicals

Titanium: seawater or chlorides

Output Type

Choose based on integration needs:

4–20 mA

HART digital

Wireless transmitters for remote sites

Environmental Rating

Look for features such as:

IP67 or IP68

High vibration resistance

Wide operating temperature range

Installation Requirements

Confirm whether you need:

Intrinsically safe barriers

Galvanic isolators

ATEX-certified cable glands

How Intrinsically Safe Pressure Transmitters Are Installed

Installation involves connecting the transmitter to a certified barrier or isolator, using approved wiring methods designed for hazardous zones.

Installation Steps

Verify the device matches the hazardous zone classification.

Install an intrinsically safe barrier between the transmitter and control panel.

Use approved IS-rated wiring, typically shielded twisted pair.

Ensure proper grounding to maintain intrinsic safety.

Inspect labeling and documentation for certification accuracy.

Correct installation ensures compliance and maintains the integrity of the intrinsically safe system.

Need barriers or isolators for your pressure transmitter loops?

Pair your IS pressure transmitters with certified barriers to keep voltage and current within safe limits.

Shop Intrinsically Safe BarriersMaintenance Requirements for Intrinsically Safe Pressure Transmitters

Maintenance is generally minimal, as intrinsically safe devices are built with robust circuits and durable materials.

Maintenance Activities

Scheduled calibration (annual or semi-annual)

Physical inspection for corrosion or buildup

Verification of certification labeling

Checking wiring, barriers, and grounding integrity

Proper maintenance ensures long-term accuracy and safety compliance.

Do Intrinsically Safe Pressure Transmitters Cost More?

Yes, intrinsically safe models typically have a higher initial cost due to specialized design and certification testing. However, they often reduce the total cost of installation.

Cost Considerations

Intrinsic safety systems do not require heavy explosion-proof housings.

Wiring and installation costs are significantly lower than explosion-proof installations.

Long-term maintenance is simpler and cheaper.

Over the lifecycle of the equipment, IS transmitters often offer a better return on investment.

Need help choosing the right intrinsically safe pressure monitoring solution?

Talk to our hazardous-area specialists, compare certified options, and get a fast quote for your facility.

Explore intrinsically safe pressure monitoring equipment:

Measurement & Calibration | Intrinsically Safe Sensors

Want to go deeper? See our guides on intrinsically safe equipment best practices and intrinsically safe vs explosion-proof.

Frequently Asked Questions (FAQ)

What’s the difference between intrinsically safe and explosion-proof transmitters?

Intrinsically safe transmitters prevent ignition by limiting electrical energy, whereas explosion-proof transmitters contain internal explosions within reinforced housings.

Can intrinsically safe pressure transmitters be used in wet environments?

Yes. Many models feature IP65–IP68 protection and corrosion-resistant materials suitable for washdown and submerged applications.

Do I need a barrier for an intrinsically safe transmitter?

Yes. IS barriers or galvanic isolators are mandatory for maintaining intrinsic safety in hazardous-area circuits.

Conclusion

Choosing the right intrinsically safe pressure transmitter is essential for safe, accurate pressure monitoring in hazardous industrial zones. By understanding certification requirements, performance specifications, environmental factors, and installation needs, you can select the optimal device for your facility. Whether monitoring pipelines, tanks, chemical reactors, or wastewater systems, intrinsically safe transmitters offer reliable measurement without risking ignition.

For ATEX, IECEx, and UL-certified components, explore the full range of hazardous-area solutions at Intrinsically Safe Store, including sensors, barriers, and integration modules.