- Intrinsically safe (IS) equipment is designed to prevent ignition by limiting electrical energy, while explosion-proof (XP) equipment contains potential internal explosions.

- IS equipment is lightweight, making it ideal for portable, low-power devices, while XP equipment is better suited for heavy-duty, high-power applications.

- Choosing between IS and XP equipment depends on the industry, type of hazardous environment, and required level of protection.

- Regulatory standards, including ATEX, IECEx, and UL, determine compliance requirements for both IS and XP equipment.

Understanding Intrinsically Safe and Explosion-Proof Equipment

Hazardous environments, such as oil refineries, chemical plants, and mining operations, require electrical equipment that prevents ignition of explosive gases, vapors, or dust. Two primary protection methods exist:

- Intrinsically safe (IS): Limits electrical energy to prevent ignition.

- Explosion-proof (XP): Uses rugged enclosures to contain internal explosions.

Both approaches are designed to protect hazardous areas, but they operate differently and serve different purposes.

Choosing the Right Equipment for Your Workplace

Selecting between intrinsically safe and explosion-proof equipment depends on your specific application, industry, and safety requirements.

- For portable, low-power devices in high-risk areas → Choose intrinsically safe equipment.

- For high-power, stationary installations in hazardous environments → Choose explosion-proof equipment.

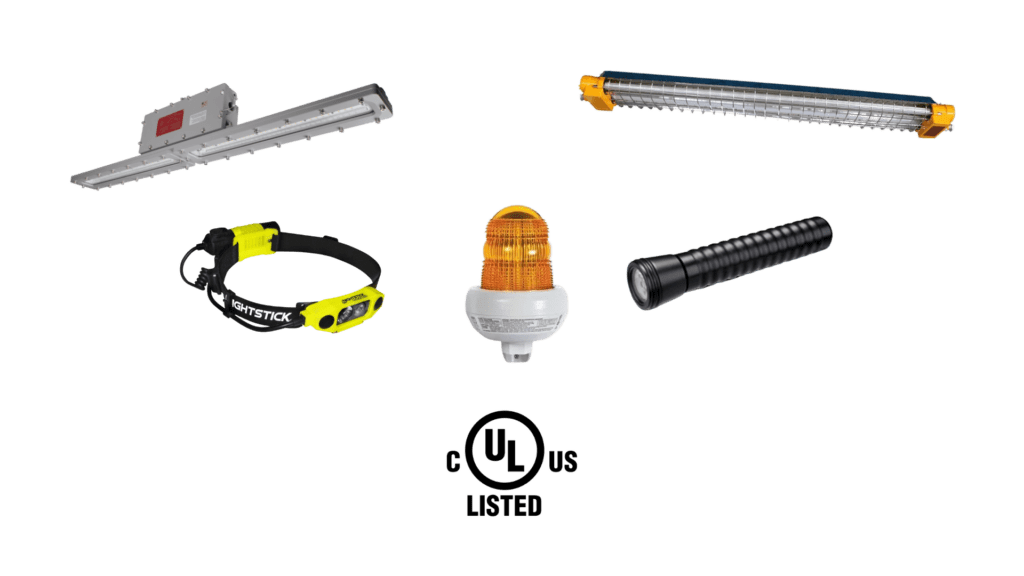

Explore ATEX, IECEx, and UL-certified solutions at Intrinsically Safe Store to ensure workplace safety and compliance.

What is Intrinsically Safe Equipment?

Definition and Functionality

Intrinsically safe equipment operates with reduced electrical and thermal energy, ensuring that it cannot generate sparks, arcs, or heat capable of igniting hazardous atmospheres. This is achieved by:

- Voltage and current limitations to eliminate ignition risks.

- Energy-limiting barriers to control power flow.

- Components that operate at low temperatures to prevent hot surfaces.

Best Applications for Intrinsically Safe Equipment

Intrinsically safe protection is ideal for low-power, portable devices, including:

- Gas detectors

- Handheld radios

- Temperature and pressure sensors

- Mobile devices used in hazardous locations

Advantages of Intrinsically Safe Equipment

- Lightweight and portable, making it easy to use in the field.

- Lower installation and maintenance costs since it does not require heavy enclosures.

- Simplifies certification under ATEX, IECEx, and UL safety standards.

- Preferred for Zones 0 and 1, where explosive gases or vapors are present frequently.

What is Explosion-Proof Equipment?

Definition and Functionality

Explosion-proof equipment does not limit energy output. Instead, it encases electrical components in a flameproof enclosure designed to contain any explosion within the device. If an internal ignition occurs, the enclosure prevents the explosion from reaching the surrounding atmosphere.

Best Applications for Explosion-Proof Equipment

Explosion-proof protection is required for high-power, stationary equipment, including:

- Motors and generators

- Control panels

- Lighting fixtures

- Electrical junction boxes

Advantages of Explosion-Proof Equipment

- Handles high-power applications without energy limitations.

- More flexible installation since it does not require energy-limiting barriers.

- Built for extreme durability, making it ideal for industrial environments.

- Used in Class I, Division 1 locations, where explosive atmospheres are likely during normal operation.

Comparing Intrinsically Safe and Explosion-Proof Equipment

| Feature | Intrinsically Safe (IS) | Explosion-Proof (XP) |

|---|---|---|

| Protection Method | Limits energy to prevent ignition | Contains internal explosions in a rugged enclosure |

| Equipment Type | Portable, low-power devices | Fixed, high-power machinery |

| Weight & Size | Lightweight and compact | Heavy and bulky |

| Certification Process | Requires IS barriers and component testing | Requires enclosure integrity testing |

| Maintenance | Easier to inspect and repair | Requires specialized maintenance |

| Common Industries | Oil & gas, mining, pharmaceuticals | Manufacturing, heavy industry, refineries |

When to Choose Intrinsically Safe Equipment

- If your application involves portable, low-power devices, such as handheld radios or sensors.

- If the hazardous area is classified as Zone 0 or Zone 1, where explosive gases or vapors are frequently present.

- If you want to reduce maintenance costs by eliminating the need for heavy enclosures.

When to Choose Explosion-Proof Equipment

- If your equipment operates at high power, such as motors, transformers, or large lighting fixtures.

- If the hazardous area is classified as Zone 1 or Zone 2, where explosive gases are occasionally present.

- If you need rugged, heavy-duty enclosures capable of withstanding harsh industrial conditions.

Regulatory Standards for IS and XP Equipment

Both IS and XP equipment must comply with global safety standards to ensure they are safe for use in hazardous environments.

| Certification | Region | Application |

|---|---|---|

| ATEX | European Union | Equipment for explosive atmospheres |

| IECEx | International | Global certification for hazardous areas |

| UL (Underwriters Laboratories) | North America | Intrinsically safe and explosion-proof devices |

| FM (Factory Mutual) | North America | Safety certification for hazardous locations |

| CSA (Canadian Standards Association) | Canada | Certification for IS and XP compliance |

Before purchasing equipment, verify that it meets the required certification for your region and industry.

FAQs About Intrinsically Safe vs. Explosion-Proof Equipment

Is intrinsically safe better than explosion-proof?

Neither is better—each serves a different function. Intrinsically safe equipment is best for low-power, portable devices, while explosion-proof equipment is necessary for high-power, stationary machinery.

Can intrinsically safe and explosion-proof equipment be used together?

Yes. Facilities often use a combination of both depending on the specific hazardous zones and equipment needs.

Which industries require IS or XP equipment?

IS equipment is commonly used in oil & gas, mining, and pharmaceuticals, while XP equipment is found in manufacturing, chemical processing, and refineries.

How do I know if my equipment is IS or XP certified?

Check the device’s labeling and documentation for compliance with ATEX, IECEx, UL, FM, or CSA certification standards.

Does IS or XP certification expire?

Certification remains valid as long as the equipment maintains compliance with regulatory inspections and safety checks.