Atex Zone 1 Fixed Lighting

Showing all 6 resultsSorted by popularity

-

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23818181%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(31.3803%202.00368%20-1.39742%2021.88553%20212.2%2049)%22%2F%3E%3Cellipse%20fill%3D%22%23f6f6f6%22%20cx%3D%22122%22%20cy%3D%2297%22%20rx%3D%22251%22%20ry%3D%2217%22%2F%3E%3Cellipse%20fill%3D%22%23adadad%22%20cx%3D%22117%22%20cy%3D%2251%22%20rx%3D%22255%22%20ry%3D%2224%22%2F%3E%3Cellipse%20fill%3D%22%23f3f3f3%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-254.75382%2011.20238%20-.58516%20-13.30714%20159.9%202.4)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

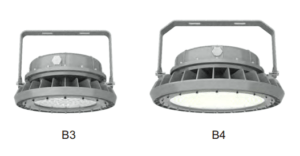

Intrinsically Safe James Industry C Series Explosion Proof Lights

$54000Price Depends on product option Make a selection to update priceImport tariffs charged -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23b5b5b5%22%20cx%3D%2267%22%20cy%3D%22111%22%20rx%3D%2222%22%20ry%3D%22219%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20d%3D%22M217.7%200l53.6-6.6%2021%20170.7-53.6%206.5z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-89.2%2037.5%2031.3)%20scale(115.80375%2016.6917)%22%2F%3E%3Cellipse%20fill%3D%22%23a6a6a6%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(17.23623%2015.41842%20-17.23789%2019.27022%20174.7%20133.1)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Intrinsically Safe James Industry A Series Explosion Proof Lights

$38880Price Depends on product option Make a selection to update priceImport tariffs charged -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23a5a5a5%22%20cx%3D%22185%22%20cy%3D%2258%22%20rx%3D%2244%22%20ry%3D%2231%22%2F%3E%3Cellipse%20fill%3D%22%23a6a6a6%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(36.52605%201.38324%20-1.13304%2029.91914%2052%2065.4)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(254.00717%20-6.27541%20.49333%2019.96838%20133%20124.4)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20d%3D%22M134.2%2021.7l-139-2.4.6-35%20139%202.4z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Intrinsically Safe James Industry B Series Explosion Proof Lights

$36720Price Depends on product option Make a selection to update priceImport tariffs charged -

FB2LEDX 120-240 Fireball Quad Color Warning Light

$87371Price Depends on product option Make a selection to update price -

FB2LEDX-012-024 Fireball Quad Color Warning Light

$87371Price Depends on product option Make a selection to update price -

CRESSA CSEXM2- 25W-63W Led Explosion Proof Light

$70859Price Depends on product option Make a selection to update priceImport tariffs charged

- Intrinsically Safe Store offers reliable and compliant Atex Zone 1 Fixed Lighting solutions designed for hazardous environments.

- Key features include explosion-proof protection, durability, energy efficiency, certified safety standards, ease of installation and maintenance, versatile designs, and customization options.

- Compliance with international standards such as ATEX, IECEx, and UL ensures safety and regulatory adherence, enhancing worker safety and operational efficiency in explosive atmospheres.

Understanding Atex Zone 1

For professionals navigating the complex landscape of hazardous area classifications, Atex Zone 1 represents a defined area where an explosive atmosphere, comprising a mixture of air and flammable substances in the form of gas, vapor or mist, is likely to occur during normal operation. It is essential to understand the implications of Atex Zone 1 to ensure the right measures are taken to prevent accidents, particularly when selecting the appropriate equipment for such environments.

Under the European directive, environments are categorized into Zones based on the frequency and duration of the occurrence of an explosive atmosphere. Atex Zone 1 (known as Zone 1) falls between Zone 0, which has an atmosphere present continuously or for long periods, and Zone 2, where an explosive atmosphere is not likely to occur in normal operation and, if it does occur, will exist for a short period only.

Working in Atex Zone 1 areas demands the highest level of safety precautions. Any electrical equipment used in this zone must be explicitly designed to prevent ignition sources. Atex Zone 1 Fixed Lighting, in this context, refers to permanent lighting solutions that are designed and certified to operate safely within Zone 1 environments without causing ignition.

These lighting fixtures are constructed to contain any sparks or high temperatures that could otherwise ignite the flammable atmosphere. Designed to mitigate risks, Atex Zone 1 Fixed Lighting solutions must adhere to stringent manufacturing standards. They are certified under the ATEX directive (which stands for “ATmosphères EXplosibles”), ensuring they are safe for use in explosive environments by preventing potential ignition sources, such as electrical sparks or high surface temperatures.

The implementation of Atex Zone 1 Fixed Lighting not only ensures compliance with health and safety regulations but also provides a robust, reliable lighting source that is critical for the safe and efficient operation of any facility operating within hazardous areas. With the potential for severe consequences in the event of an ignition, the importance of understanding and implementing the correct lighting in Atex Zone 1 environments cannot be overstated.

The implementation of Atex Zone 1 Fixed Lighting not only ensures compliance with health and safety regulations but also provides a robust, reliable lighting source that is critical for the safe and efficient operation of any facility operating within hazardous areas. With the potential for severe consequences in the event of an ignition, the importance of understanding and implementing the correct lighting in Atex Zone 1 environments cannot be overstated.

Intrinsically Safe Store acknowledges the intricacies involved in outfitting hazardous areas and offers an extensive selection of Atex Zone 1 Fixed Lighting solutions. Our lighting products meet all necessary international safety standards, providing illumination that ensures both safety and operational efficiency in these critical environments.

The Importance of Fixed Lighting in Hazardous Areas

Fixed lighting is critical in hazardous environments where the risk of explosions is high, such as in oil and gas operations, mining sites, and pharmaceutical production facilities. Atex Zone 1 fixed lighting solutions are specifically designed to provide safe, reliable illumination in these areas where the presence of flammable gases, vapours, or dust can create potentially explosive atmospheres.

Proper illumination is vital for several reasons:

- Visibility and Safety: Adequate lighting ensures that employees can see clearly, identify hazards, and navigate safely through the work environment. This is especially important in locations where complex machinery is operated, and precision work is done.

- Accident Prevention: Many workplace accidents can be attributed to poor lighting. Good lighting reduces the likelihood of mistakes and slips, trips, and falls, which are common causes of injury in industrial settings.

- Operational Continuity: In hazardous areas, it is essential to minimize any risk of ignition. Atex Zone 1 fixed lighting provides a stable light source that does not create sparks that could ignite explosive gases or particles. This ensures operations can continue without the threat of a lighting-related incident.

- Compliance with Safety Regulations: Adhering to regulations like the ATEX directive is non-negotiable for businesses operating in potentially explosive environments. Using Atex Zone 1 certified fixtures ensures compliance, thus avoiding penalties and ensuring a safer workplace.

Choosing the correct type of fixed lighting, such as those offered by Intrinsically Safe Store, which complies with Atex Zone 1 certification, is not simply a matter of regulatory compliance but a critical step towards ensuring the well-being of personnel and the smooth operation of potentially hazardous work sites.

Key Features of Atex Zone 01 Fixed Lighting

Atex Zone 1 Fixed Lighting systems are indispensable in environments where safety cannot be compromised. Understanding the critical features these lighting solutions offer is paramount for industry professionals. Here are some of the key features of Atex Zone 1 Fixed Lighting available at Intrinsically Safe Store:

Explosion-Proof Protection: Atex Zone 1 Fixed Lighting is designed to prevent any potential source of ignition. With robust enclosures, these lights can contain sparks and resist explosions, ensuring that they do not ignite flammable materials in the atmosphere. This is particularly important in industries such as oil and gas, where explosive gases and vapors may be present.

Durability: Built to withstand the extreme conditions of hazardous environments, Atex Zone 1 lights are constructed from high-quality, corrosion-resistant materials. The durability of these lights ensures a long service life, reducing the frequency of replacements and maintenance costs.

Energy Efficiency: Modern Atex Zone 1 lighting solutions often incorporate LED technology. LEDs are not only more energy-efficient than traditional bulbs, but they also have a longer life span. This results in lower energy costs and a reduction in the environmental impact of lighting in hazardous zones.

Certified Safety Standards: Products in the Intrinsically Safe Store meet stringent international safety standards, such as ATEX and IECEx. These certifications confirm that the lights are safe to use in explosive atmospheres and comply with the latest safety regulations.

Ease of Installation and Maintenance: Ease of installation and minimal maintenance requirements are important considerations. Atex Zone 1 Fixed Lighting is designed with these factors in mind, providing user-friendly fixtures that can be quickly installed and maintained, even in difficult-to-access locations.

Versatile Designs: Atex Zone 1 Fixed Lighting comes in various designs to suit different applications and preferences. From floodlights to linear lights, each option provides the appropriate illumination needed for safety and productivity in hazardous zones.

Customization: Understanding that each hazardous environment has unique requirements, Atex Zone 1 Fixed Lighting can be customized. Customers can choose specific light outputs, color temperatures, and additional features such as emergency battery backups to fit their specific needs.

Intrinsically Safe Store ensures that the Atex Zone 1 Fixed Lighting solutions it offers are optimized for the harsh and hazardous conditions specific to industries like oil and gas, mining, and pharmaceuticals. With a commitment to providing certified and quality lighting options, our products stand as a testament to our value proposition as the single source for any Intrinsically Safe and Explosion-Proof certified solutions.

Impact of Atex Zone 1 Lighting on Worker Safety

The implementation of Atex Zone 1 Fixed Lighting in hazardous environments is more than a compliance requirement—it plays a critical role in ensuring worker safety. Atex Zone 1 lighting systems are designed to operate safely in areas where an explosive atmosphere is likely to occur in normal operation. This mitigates prevalent risks by providing reliable and consistent illumination, even in the event of gas leaks or the presence of flammable dust.

Worker safety is directly influenced by the quality and reliability of the lighting in explosive atmospheres. Proper lighting helps to prevent accidents by allowing workers to clearly see potential hazards, thereby reducing the risk of ignition sources through accidental impacts or drops. Atex Zone 1 Fixed Lighting systems are also designed to be robust, with a focus on preventing the ingress of dust and moisture. This durability ensures continuous operation without interruption, which is vital for sustained safe working conditions.

Worker safety is directly influenced by the quality and reliability of the lighting in explosive atmospheres. Proper lighting helps to prevent accidents by allowing workers to clearly see potential hazards, thereby reducing the risk of ignition sources through accidental impacts or drops. Atex Zone 1 Fixed Lighting systems are also designed to be robust, with a focus on preventing the ingress of dust and moisture. This durability ensures continuous operation without interruption, which is vital for sustained safe working conditions.

Good visibility is essential for accurate and secure operations. These lighting systems are typically engineered to cast light that closely mimulates natural daylight, which helps in maintaining workers’ circadian rhythms and reducing eye strain during long shifts. This contributes significantly to a safer and more alert workforce, which is crucial in environments where precision and attention to detail can mean the difference between safe operations and catastrophic events.

Furthermore, Atex Zone 1 lighting solutions often come with emergency lighting features. In the event of power failure, these emergency systems provide enough illumination for workers to safely evacuate the area or perform shutdown procedures, which is imperative for avoiding accidents during a power outage or other emergency situations.

By investing in Atex Zone 1 Fixed Lighting, companies enhance the safety and wellbeing of their employees. These lights not only meet all necessary safety compliance standards but also serve as a crucial component in a company’s safety infrastructure, leading to a culture where safety is paramount, and risks are minimized. Intrinsically Safe Store understands this priority and provides a comprehensive selection of certified Atex Zone 1 Fixed Lighting solutions to meet the needs of any operation in hazardous environments.

Compliance Standards for Atex Zone 1 Lighting

Selecting the right lighting for explosive atmospheres is not just a matter of operational efficiency; it is a critical safety decision. Atex Zone 1 Fixed Lighting must comply with stringent regulatory standards to ensure they can operate safely in hazardous environments without igniting the surrounding atmosphere.

Understanding the ATEX Directive

The ATEX Directive, derived from the French title “ATmosphères EXplosibles,” is a set of European Union regulations designed to ensure the safety of equipment used in explosive atmospheres. ATEX outlines two key EU directives: 2014/34/EU for equipment, which includes fixed lighting, and 1999/92/EC for workplace safety.

The Significance of Zone 1 Classification

In terms of fixed lighting within the ATEX directive, Zone 1 refers to an area where an explosive atmosphere is likely to occur in normal operation occasionally. For equipment to be certified for Zone 1, it must offer an advanced level of protection. Atex Zone 1 Fixed Lighting fixtures are constructed to prevent arcs, sparks, and high temperatures that could ignite gases or vapors present in these environments.

Compliance with International IECEx Standards

In addition to ATEX certification, it is also crucial to consider the International Electrotechnical Commission’s system for certification to standards relating to equipment for use in explosive atmospheres (IECEx). IECEx offers an international means of proof of compliance with IEC standards for electrical equipment within explosive atmospheres, including fixed lighting.

UL Certification

The Underwriters Laboratories (UL) certification is another crucial compliance metric, especially for products intended for the North American market. UL certification ensures that fixed lighting has been tested to meet specific, defined standards for safety against fire and explosion risks, among other hazards.

Ensuring Compliance

Intrinsically Safe Store ensures that all Atex Zone 1 Fixed Lighting options available comply with ATEX, IECEx, and if applicable, UL standards. Each lighting solution within our inventory comes with comprehensive documentation that certifies its compliance with these rigorous standards, helping users meet their legal obligations for safety, and providing peace of mind that they are investing in reliable, safe equipment.

By adhering to these standards, companies protect not just their facilities and processes but, most importantly, the lives of their employees working in hazardous environments. The extensive range of Atex Zone 1 Fixed Lighting solutions offered by Intrinsically Safe Store come with the assurance that safety is the paramount priority, reflecting our commitment to serving our customers with products that meet the highest international safety standards.

FAQs on ATEX Zone 1 Fixed Lighting

What types of hazards are present in ATEX Zone 1 areas that require special lighting?

ATEX Zone 1 areas are classified as places where an explosive atmosphere is likely to occur under regular operating conditions. The hazards present in these zones typically include flammable gases, mists or vapors, or combustible dust clouds. Due to the high risk of ignition, lighting equipment must be designed to prevent the release of any sparks or high temperatures that could cause an explosion.

What criteria must ATEX Zone 1 fixed lighting meet?

ATEX Zone 1 fixed lighting must meet the European Directive 2014/34/EU requirements for equipment intended for use in explosive atmospheres. These requirements include specific design measures to ensure that the lighting will not ignite the atmosphere, such as enclosure integrity, thermal dissipation, and spark prevention. The lighting must be tested and certified by a notified body to ensure that it meets the stringent ATEX standards for Zone 1 application.

How is ATEX Zone 1 fixed lighting installed safely?

The safe installation of ATEX Zone 1 fixed lighting involves several considerations. The electrical installation must comply with ATEX installation requirements and local electrical codes. All electrical connections should be made in accordance with the lighting manufacturer’s instructions. Additionally, wiring methods must consider the prevention of arcs and sparks, and maintenance should be performed only by qualified personnel to ensure ongoing safety and compliance.

How do I choose the right ATEX Zone 1 fixed lighting for my facility?

Choosing the right ATEX Zone 1 fixed lighting involves assessing your facility’s specific needs. This includes understanding the type of explosive atmosphere, the physical space requirements, the desired brightness level, and the necessary functionality. It is crucial to consult with experts or trusted suppliers who can guide you to options that meet ATEX standards and to ensure that the product is suitable for the environmental conditions of your Zone 1 area.

What are the differences between ATEX Zone 0, 1, and 2 lighting requirements?

ATEX Zone 0 lighting requirements are the most stringent, as this zone is where an explosive atmosphere is continuously present. Lighting equipment designed for Zone 0 must ensure the highest level of safety under all circumstances. Zone 1 lighting requirements are less strict than Zone 0 but require protection against explosive atmospheres that are likely to occur during normal operation. Zone 2 lighting is for use in areas where an explosive atmosphere is not likely to occur in normal operation and if it does occur, it will exist only for a short time. Each zone has specific certification and safety requirements that the lighting products must adhere to, with Zone 0 being the most demanding and Zone 2 the least.