Class 1 Division 1 Camera

Discover our top-tier selection of Class 1 Division 1 cameras, meticulously engineered to ensure safety and reliability in environments with continuous or frequent exposure to hazardous gases and vapors. Ideal for industries such as oil and gas, chemical processing, and petrochemical facilities, these cameras are sourced from leading manufacturers and meet the highest safety standards.

Show moreEnsure dependable performance in highly hazardous conditions, enhance workplace safety, improve security, and maintain compliance with our durable and high-quality camera solutions, designed specifically for these demanding industrial settings.

Showing all 5 resultsSorted by popularity

-

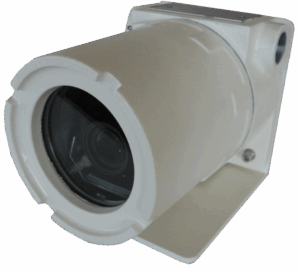

IVC AMZ-HD41-3 Explosion Proof CCTV Camera

$3,19400Price Depends on product option Make a selection to update price -

IVC AMZ-3041-2 Explosion-Proof Fixed CCTV Camera

$2,92800Price Depends on product option Make a selection to update price -

IVC AMZ-HD47-4 Class 1 Division 1 Industrial IP Camera – 4× Optical Zoom, NEMA 4X Stainless Steel

$3,79620 -

Intrinsically Safe ATEX Zone 0 Inspection Camera

$9,86040 -

IVC APTZ-3045-04 Explosion-Proof PTZ Camera

$14,60000

- Equipments designed for hazardous environments must meet stringent safety and compliance standards.

- Class 1 Division 1 cameras offer enhanced safety, high-quality imaging, and robust performance in dangerous conditions.

- Implementing these cameras in industries like oil and gas can improve operational efficiency and ensure regulatory adherence.

Understanding Class 1 Division 1 Cameras

A Class 1 Division 1 camera is a specialized device engineered to operate safely in environments where flammable gases, vapors, or liquids may be present under normal operating conditions. These hazardous areas require equipment designed to prevent ignition of explosive atmospheres, ensuring the safety of operators and infrastructures.

Key Features

- Intrinsically Safe Design:Class 1 Division 1 cameras are intrinsically safe, meaning they are built to prevent sparks or heat that could cause an explosion. This feature is crucial for industries such as oil and gas, chemical plants, and refineries.

- Durability and Robustness:These cameras are designed to withstand harsh conditions, including extreme temperatures, moisture, and physical impacts. Their robust construction ensures reliable performance in rigorous environments.

- High-Quality Imaging:Despite their rugged build, Class 1 Division 1 cameras often feature high-resolution sensors and advanced imaging technologies. This allows for clear and precise monitoring in hazardous areas, facilitating better decision-making and safety management.

- Compliance:Equipments must meet stringent safety standards and certifications, such as those set by Underwriters Laboratories (UL) and the International Electrotechnical Commission (IEC). Compliance ensures that the cameras are safe to use in designated hazardous areas.

Applications in the Oil and Gas Industry

In the oil and gas industry, reliable visual monitoring is crucial for maintaining operational safety and complying with regulatory requirements. Class 1 Division 1 cameras are often deployed for:

- Pipeline Monitoring: Ensuring the integrity of pipelines by detecting leaks or damages early.

- Offshore Rigs: Monitoring operations on offshore platforms where explosive gases might be present.

- Storage Facilities: Overseeing the safe storage of flammable materials to prevent accidents.

By opting for Class 1 Division 1 cameras, companies in the oil and gas sector can enhance the safety and efficiency of their operations while ensuring compliance with safety standards.

Key Features of Class 1 Division 1 Cameras

Class 1 Division 1 cameras are specifically engineered to meet stringent safety and operational requirements in hazardous environments. Here are some of the key features that make these cameras indispensable tools in industries such as oil and gas:

Intrinsic Safety

Designed for safe operation in potentially explosive atmospheres, Class 1 Division 1 cameras are engineered with components that intrinsically prevent ignition. This ensures that the cameras will not trigger any sparks or heat that could ignite hazardous substances.

Rugged Construction

Built to withstand harsh environmental conditions, these cameras often feature durable housings made from materials such as stainless steel or reinforced polycarbonate. They are resistant to impact, vibration, dust, and moisture, making them reliable in challenging field conditions.

High-Resolution Imaging

Despite their rugged design, Class 1 Division 1 cameras do not compromise on image quality. They typically offer high-resolution imaging capabilities, enabling clear and detailed visual inspection. This is crucial for identifying leaks, corrosion, or other maintenance needs in hazardous areas.

Night Vision and Low-Light Performance

For industries operating around the clock, the ability to capture clear images in low-light conditions is indispensable. Many Class 1 Division 1 cameras come equipped with infrared sensors or other low-light imaging technologies, providing excellent visibility even in the absence of natural light.

Wireless Connectivity

Modern Class 1 Division 1 cameras often feature wireless connectivity options, allowing for real-time data transmission and remote monitoring. This is particularly useful for reducing the need for personnel to enter hazardous areas, thereby enhancing overall safety.

Compliance with Industry Standards

These cameras comply with various industry standards, ensuring that they meet all necessary safety and performance criteria. Compliance with standards such as ATEX, IECEx, and North American certifications is a testament to their reliability in hazardous environments.

Ease of Integration

Class 1 Division 1 cameras are designed to integrate seamlessly with existing surveillance and monitoring systems. This ease of integration ensures that organizations can enhance their operational safety and efficiency without the need for extensive system overhauls.

The Importance of Explosion-Proof Cameras

In hazardous environments, safety and reliability are paramount. Explosion-proof cameras, specifically class 1 division 1 cameras, play a crucial role in maintaining these standards. These specialized cameras are designed to operate safely in areas where ignitable concentrations of flammable gases, vapors, or liquids are present. This is particularly important in industries such as oil and gas, chemical processing, and mining, where the risk of explosions is significant.

Ensuring Compliance and Safety

Class 1 division 1 cameras are built to meet stringent safety and compliance standards. These devices are rigorously tested to ensure they can withstand harsh conditions and prevent any spark or heat that could ignite a volatile atmosphere. By using these specialized cameras, companies can adhere to regulations such as OSHA and NFPA standards, ensuring the safety of their operations and employees.

Enhanced Monitoring and Surveillance

The ability to safely monitor and capture real-time data in hazardous environments is invaluable. Explosion-proof cameras provide high-resolution imagery and video, which is essential for detailed inspections, remote monitoring, and maintaining operational oversight. This enhanced surveillance capability helps in promptly identifying and addressing potential safety hazards, thus preventing accidents before they occur.

Durability and Performance

Class 1 division 1 cameras are engineered to be robust and durable, capable of withstanding extreme temperatures, high pressures, and corrosive environments. This durability ensures long-term performance and reliability, minimizing downtime and reducing maintenance costs. These cameras are designed to deliver consistent and high-quality performance, even under the most challenging conditions.

Versatility and Application

Explosion-proof cameras are versatile tools that can be deployed in various parts of an industrial site, from pipeline monitoring to rig inspections and beyond. Their adaptability allows them to be used in both fixed and portable setups, making them ideal for a range of applications. This flexibility ensures that no matter the specific requirements of your operation, there is a class 1 division 1 camera solution that fits your needs.

At The Intrinsically Safe Store, we recognize the critical importance of explosion-proof cameras in maintaining safety and efficiency in hazardous environments. Our extensive range of class 1 division 1 cameras is designed to meet the highest standards of safety and performance, ensuring that your operations remain secure and compliant.

Selecting the Right Camera for High-Risk Environments

When it comes to capturing images and videos in high-risk environments, choosing the right class 1 division 1 camera is not just a matter of preference—it’s a critical safety decision. Companies in industries such as oil and gas, chemical processing, and mining need to adhere to stringent safety standards to ensure the well-being of their workforce and the protection of their assets.

Understanding the Certification

A Class 1 Division 1 certification ensures that a camera is intrinsically safe for use in environments where explosive gases or vapors may be present. This certification is vital for preventing catastrophic failures and ensuring compliance with local and international safety regulations. It’s essential to verify that the camera you choose meets these stringent criteria.

Key Features to Consider

When selecting a class 1 division 1 camera, there are several key features to consider:

- Durability: The camera should be robust enough to withstand harsh conditions, including extreme temperatures, dust, and moisture.

- Image Quality: High-resolution imaging capabilities are crucial for detailed inspection and documentation tasks.

- Battery Life: Long battery life ensures the camera can operate for extended periods without requiring frequent recharges or battery changes.

- Ease of Use: The camera should be user-friendly, with intuitive controls and interfaces that allow for easy operation even while wearing protective gear.

- Connectivity: Advanced connectivity features, such as Wi-Fi and Bluetooth, can facilitate real-time data transfer and remote monitoring.

Camera Solutions from the Intrinsically Safe Store

At the Intrinsically Safe Store, we offer a curated selection of class 1 division 1 cameras tailored for hazardous environments. Our comprehensive solutions are designed to meet the unique needs of various industries, helping you achieve operational efficiency while maintaining the highest safety standards. From rugged construction to superior imaging technology, our cameras are built to perform and protect in the most challenging conditions.

At the Intrinsically Safe Store, we offer a curated selection of class 1 division 1 cameras tailored for hazardous environments. Our comprehensive solutions are designed to meet the unique needs of various industries, helping you achieve operational efficiency while maintaining the highest safety standards. From rugged construction to superior imaging technology, our cameras are built to perform and protect in the most challenging conditions.

By focusing on these factors, you can make an informed decision and equip your team with the right tools for safe and efficient operations in high-risk settings.

Benefits of Implementing Class 1 Division 1 Cameras

Integrating Class 1 Division 1 cameras into hazardous work environments, particularly in the oil and gas industry, offers numerous advantages. Below, we outline some key benefits:

Enhanced Safety and Compliance

Class 1 Division 1 cameras are specifically designed to operate safely in environments with explosive gases, vapors, or dust. By using these cameras, companies can ensure compliance with industry safety standards and regulations, thereby minimizing the risk of accidents and enhancing overall workplace safety.

Real-Time Monitoring and Inspection

These specialized cameras enable real-time monitoring and inspection of critical areas without putting personnel at risk. This allows for early detection of potential issues, such as gas leaks or equipment malfunctions, facilitating timely intervention and maintenance.

Increased Operational Efficiency

By reducing the need for physical presence in hazardous areas, companies can conduct inspections and monitoring tasks more efficiently. This not only minimizes downtime but also optimizes resource allocation, leading to increased operational efficiency.

High-Quality Imagery and Data Collection

Class 1 Division 1 cameras are equipped with advanced imaging technology, providing high-quality visuals and crucial data even in challenging conditions. This ensures that all necessary information for decision-making and reporting is accurate and reliable.

Versatility and Durability

Built to withstand harsh conditions, these cameras are extremely durable. Their versatility allows them to be used in various applications, from pipeline inspections to monitoring storage facilities, ensuring that all safety and operational requirements are met effectively.

Implementing Class 1 Division 1 cameras not only bolsters safety measures but also drives efficiency and accuracy, making them an indispensable tool for companies operating in hazardous environments. Whether you are conducting routine inspections or need continuous monitoring, these cameras offer a robust and compliant solution.

FAQs About Class 1 Division 1 Cameras

What certifications do Class 1 Division 1 cameras have?

Class 1 Division 1 cameras typically carry certifications such as UL (Underwriters Laboratories), ATEX (Atmosphères Explosibles), and IECEx (International Electrotechnical Commission Explosive). These certifications validate that the camera has undergone rigorous testing to ensure it meets safety standards required for operation in hazardous locations.

What environments require a Class 1 Division 1 camera?

Environments such as oil and gas refineries, chemical plants, and mining operations often require Class 1 Division 1 cameras. These settings have a high risk of explosive gases, vapors, or dust, which necessitate the use of intrinsically safe equipment to prevent ignition.

What are the differences between Class 1 Division 1 and Class 1 Division 2 cameras?

Class 1 Division 1 cameras are designed for environments where hazardous conditions are present continuously or intermittently under normal operating conditions. In contrast, Class 1 Division 2 cameras are suitable for areas where hazardous conditions are present only under abnormal circumstances, such as during equipment failure or maintenance.

What industries commonly use Class 1 Division 1 cameras?

Industries such as oil and gas, chemical manufacturing, pharmaceuticals, and mining frequently use Class 1 Division 1 cameras. These sectors typically operate in environments where the risk of explosion necessitates stringent safety measures.

Are Class 1 Division 1 cameras explosion-proof?

Yes, Class 1 Division 1 cameras are designed to be explosion-proof. They are constructed to prevent any internal sparks or high temperatures from igniting the surrounding hazardous atmosphere, therefore ensuring safe operation in extremely volatile environments.