Class 1 Division 1 Gas Detector

Showing all 6 resultsSorted by popularity

-

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23c3520c%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-.52253%20106.48691%20-53.3532%20-.2618%20125.3%20119.2)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22222%22%20cy%3D%22152%22%20rx%3D%2246%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-37.13142%20.36088%20-2.4782%20-254.98796%2025%20138.7)%22%2F%3E%3Cellipse%20fill%3D%22%23955529%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(29.1563%20-1.12007%201.60906%2041.88493%20122.5%2077)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

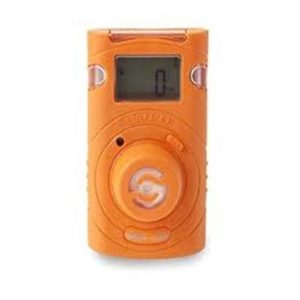

SENKO SGT Portable Gas Detector

$41293Price Depends on product option Make a selection to update priceImport tariffs charged -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23abbd4d%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-18.46774%2061.9488%20-53.70754%20-16.01091%20121%2077.4)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-56.8417%20248.58403%20-49.69066%20-11.36236%20219.3%20141)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(162.4%201.5%2062.8)%20scale(57.02586%20255.00001)%22%2F%3E%3Cellipse%20fill%3D%22%23b4bf79%22%20cx%3D%22124%22%20cy%3D%2283%22%20rx%3D%2243%22%20ry%3D%2243%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

SENKO SI-100C Fixed Gas Detector

$48972Price Depends on product option Make a selection to update price -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23737370%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-7.5%20623.3%20-951.3)%20scale(55.3271%2059.77227)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-168%20118.4%2036.3)%20scale(51.04617%20254.99999)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%2218%22%20cy%3D%22190%22%20rx%3D%2262%22%20ry%3D%22223%22%2F%3E%3Cellipse%20fill%3D%22%23626264%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(11.70168%20-20.1642%2020.61778%2011.9649%20126%2073)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

SENKO SI-100 Fixed Gas Detector

$74844Price Depends on product option Make a selection to update priceImport tariffs charged -

%22%20transform%3D%22translate(.9%20.9)%20scale(1.74219)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23b07700%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-53.86295%20-.20023%20.36901%20-99.26568%2079.2%20128)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-24.71268%20-.07972%20.5516%20-170.99911%20157.1%20138)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(158.66908%20-1.3907%20.217%2024.75863%2047.7%2012.4)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cy%3D%22166%22%20rx%3D%2223%22%20ry%3D%22171%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

SENKO SGT- P Replaceable Single-Gas Detector

$18802Price Depends on product option Make a selection to update priceImport tariffs charged -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23c3520c%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-.52253%20106.48691%20-53.3532%20-.2618%20125.3%20119.2)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22222%22%20cy%3D%22152%22%20rx%3D%2246%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-37.13142%20.36088%20-2.4782%20-254.98796%2025%20138.7)%22%2F%3E%3Cellipse%20fill%3D%22%23955529%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(29.1563%20-1.12007%201.60906%2041.88493%20122.5%2077)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

SENKO iGas Detector CO2

$64798Import tariffs charged -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23c05e14%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-46.22748%204.7517%20-7.55904%20-73.53903%20124%20100.4)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20d%3D%22M174.3%20221l8.5-244%20111%204-8.6%20243.8z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%2225%22%20cy%3D%22125%22%20rx%3D%2243%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%238e5525%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-4.3182%20-25.93673%2023.67018%20-3.94085%20124.1%2071.4)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

SENKO MGT Portable Multi Gas Detector

$71257Price Depends on product option Make a selection to update priceImport tariffs charged

- Understand the significance of Class 1 Division 1 gas detectors in mitigating explosion risks in hazardous environments.

- Learn about the features, technologies, and compliance standards essential for these detectors.

- Discover the industrial applications where Class 1 Division 1 gas detectors are critical for safety and regulatory compliance.

Introduction to Class 1 Division 1 Gas Detectors

In hazardous environments where flammable gases or vapors pose a constant threat, safety solutions must prioritize preventing ignition and ensuring real-time hazard detection. Class 1 Division 1 (C1D1) gas detectors are at the forefront of such safety measures, specifically designed to operate safely in areas where explosive atmospheres exist under normal working conditions. These advanced devices are integral to the safety protocols of industries such as oil and gas, petrochemicals, and chemical manufacturing.

Understanding what makes a gas detector C1D1-certified and its application in various industrial scenarios is critical for safety professionals. This article explores the intricate features, technology, and applications of these detectors, emphasizing their role in safeguarding personnel and assets.

The Significance of Class 1 Division 1 Certification

Class 1 Division 1 (C1D1) is a classification outlined by the National Electrical Code (NEC), specifically referring to hazardous locations with flammable gases or vapors. A gas detector with this certification ensures that it can operate safely under these extreme conditions.

Understanding C1D1 Environments

C1D1 environments are areas where:

- Flammable gases or vapors are present under normal operating conditions.

- Hazardous conditions exist frequently due to the operational environment.

The certification guarantees that the equipment, including gas detectors, is explosion-proof or intrinsically safe to prevent ignition.

Features of C1D1 Gas Detectors

- Robust Housing: Designed to withstand internal explosions and prevent flame propagation.

- Intrinsic Safety: Limits electrical energy to prevent sparking or excessive heat.

- Comprehensive Sensor Technology: Includes catalytic bead, infrared, or electrochemical sensors tailored to detect specific gases.

- Durability: Built to endure extreme temperatures, humidity, and corrosive conditions.

Technology Behind Class 1 Division 1 Gas Detectors

C1D1 gas detectors employ cutting-edge technologies to ensure reliable performance in hazardous areas.

Sensor Types

- Catalytic Bead Sensors: Detect combustible gases by measuring heat generated during oxidation.

- Infrared Sensors: Use IR absorption to identify hydrocarbon gases, suitable for environments where oxygen levels vary.

- Electrochemical Sensors: Ideal for toxic gases like hydrogen sulfide, these sensors measure electrical changes caused by gas interaction.

Wireless Integration and Connectivity

Modern gas detectors incorporate wireless technologies for real-time monitoring and remote alerts, providing an added layer of safety and operational efficiency.

Battery and Power Management

C1D1 gas detectors often feature intrinsically safe batteries or energy-limiting circuits to prevent overheating, ensuring continuous safe operation even during power fluctuations.

Applications of C1D1 Gas Detectors Across Industries

The versatility of C1D1 gas detectors makes them indispensable in a range of industries, each facing unique challenges and risks.

Oil and Gas Industry

Detecting leaks of flammable hydrocarbons like methane is vital to preventing explosions in refineries and rigs.

Chemical Manufacturing

Toxic gas detection ensures compliance with OSHA and EPA standards while protecting workers.

Pharmaceutical Industry

Monitoring solvents and vapors in production areas prevents ignition hazards, safeguarding personnel and processes.

Wastewater Treatment

Hydrogen sulfide detection mitigates risks from biogas accumulation in treatment facilities.

Compliance and Regulatory Standards

C1D1 gas detectors must comply with stringent international and regional standards to ensure reliability and safety.

Certification Bodies

- National Electrical Code (NEC): Governs the classification of hazardous areas and equipment requirements.

- IECEx and ATEX: Ensure compliance in international markets, often overlapping with NEC classifications.

- UL and CSA: Certify devices for safe operation in North American hazardous locations.

Testing and Maintenance

Routine calibration and maintenance are essential for detectors to remain compliant and effective.

Choosing the Right C1D1 Gas Detector

When selecting a gas detector, consider the following:

Environment Compatibility

Choose sensors suited to the specific gases and conditions of your facility.

Durability

Ensure the device can withstand harsh environmental factors, such as high temperatures or corrosive agents.

Ease of Use

Wireless connectivity, compact design, and intuitive interfaces enhance usability and deployment flexibility.

Conclusion

Class 1 Division 1 gas detectors are critical in ensuring safety and compliance in environments prone to explosive risks. By understanding their technology, applications, and compliance standards, industries can make informed decisions to safeguard their operations.

FAQs

What does Class 1 Division 1 mean for gas detectors?

It signifies the detector’s ability to operate safely in areas where flammable gases are consistently present.

Are all gas detectors suitable for C1D1 environments?

No, only those certified as intrinsically safe or explosion-proof can be used in such environments.

How often should a C1D1 gas detector be calibrated?

Calibration should follow the manufacturer’s recommendations, typically every 3-6 months, to ensure accuracy and compliance.

Can wireless gas detectors be used in C1D1 areas?

Yes, provided they are certified for use in hazardous environments, wireless detectors offer real-time monitoring and alert capabilities.

What is the lifespan of a typical C1D1 gas detector?

With proper maintenance, C1D1 gas detectors can last 5-10 years, depending on the model and usage conditions.