Description

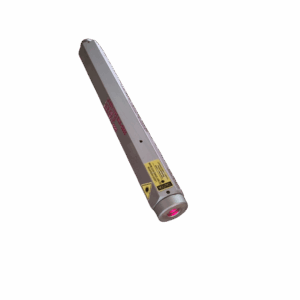

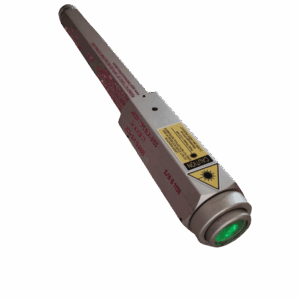

APG Intrinsically Safe Modbus Display Series: MDI Sensor:

Introducing the APG Intrinsically Safe Modbus Display Series: MDI Sensor, meticulously crafted to excel in hazardous environments. Its robust design, ensconced within an IP66-rated environmentally sealed housing, guarantees resilience against dust and water exposure, maintaining peak performance even in the harshest conditions. A large, 0.4-inch character, 5-digit display ensures optimal visibility, empowering seamless monitoring and control. User convenience takes precedence with selectable units of measure, enabling effortless transitions between various metrics, catering to diverse operational needs, including barrels, cubic inches, liters, gallons, and custom units.

Furthering its adaptability, the MDI offers software-based switchable power control for connected sensors, allowing for dynamic power management tailored to specific operational requirements. Additionally, its auxiliary connection paves the way for remote activation, facilitating control from distant locations. This innovative feature amplifies flexibility and accessibility, ensuring monitoring and control capabilities regardless of proximity to the unit.

Unified in its robustness, user-friendly interface, and remote accessibility, the MDI Intrinsically Safe Modbus Display emerges as a stalwart solution for comprehensive hazardous environment management. Its ability to endure harsh conditions, facilitate versatile metric displays, enable efficient power control, and offer remote accessibility cements its position as an indispensable component for seamless monitoring and control in hazardous settings, ensuring both safety and operational efficiency.

Features:

- Large Display: Full 5-digit display with 0.4-inch characters for enhanced visibility.

- Environmentally Sealed: Housing designed to IP66 standards, providing protection against dust and water.

- Selectable Units: Users can choose from various units of measure including barrels, cubic inches, liters, cubic meters, gallons, million cubic feet, cubic feet, or custom units, catering to diverse needs.

- Software-Based Power Control: Allows for switchable power control for connected sensors, enabling efficient power management as per specific requirements.

- Auxiliary Connection: Permits remote activation of the MDI, enhancing accessibility and control even from distant locations.

MDI controlling single IS sensor

- Single MDI Control in Hazardous Zones: The MDI manages a single IS sensor without requiring additional barriers, regardless of Zone 0 or Zone 1 placement.

- Zone Location Compliance: Situated in Zone 1, the MDI adheres to hazardous area classifications while effectively controlling the sensor.

- Battery-Powered MDI: The MDI operates on battery power, enabling flexibility and portability. It allows software-based switchable power control for the connected sensor, enhancing efficient power management.

- Independent Control: There’s no reliance on an external controller; the MDI functions autonomously to oversee and regulate the sensor.

- Integrated Settings Management: Sensor settings adjustments occur seamlessly through the MDI’s interface using its buttons, providing a user-friendly and integrated approach to control and configuration.

MDI controlling single IS sensor with Passive Control Equipment

- MDI and IS Sensor Control: A single MDI in Zone 1 manages an IS sensor in Zone 0 or Zone 1 without additional barriers.

- Battery-Powered Efficiency: Battery-operated MDI allows software-based power control for efficient sensor management.

- External Controller Interaction: An external controller passively reads data from the MDI and can activate it as needed.

- Safety Barrier Requirement: An approved IS Barrier ensures secure data transfer between Passive Control Equipment and the MDI.

- Auxiliary Connection for Accessibility: MDI requires an auxiliary connection for enhanced remote activation or control.

- User-Friendly Sensor Settings: Sensor settings adjustments are seamlessly managed via the MDI’s interface for easy control and configuration.

Specifications:

| Technical Data | |

| Performance | |

| RS-485 (Modbus RTU): | 2400, 9600, 19200, 38400 baud rates |

| Display readings: | volume, level, distance, pressure |

| Connectivity | |

| Control: | Modbus RTU |

| Online Access/Control | Via APG’s Tank Cloud & RST-5003 or LOE controller (non-IS installations only) |

| Environmental | |

| Protection rating: | IP66 |

| Storage Temp: | -49º - 194ºF (-45º - 90ºC) |

| Operating Temp: | -22º - 185ºF (-30º - 85ºC) |

| Physical | |

| Aluminum housing | |

| Display: | 5 digit LCD, 0.4 in. digits |

| Programming | |

| Programmable Features: | User selectable units of measure |

| Master mode | |

| Auto-Of | |

| Electrical | |

| Battery Power: | 3 - 3.6V Lithium |

| Low battery detection with 25% increments | |

| Certification | |

| cCSAus Certificate CSA19CA70219728: | Ambient: -30º to 85ºC |

| Class I, Zone 1 | |

| AEx ib [ia Ga] IIB 142°C (T3) Gb | |

| Ex ib [ia Ga] IIB 142°C (T3) Gb | |

| ATEX Certificate Sira 18ATEX2289XX: | II 2G Ex ib [ia Ga] IIB 142°C (T3) Gb |

| Ta = -30º to 85ºC | |

| IECEx Certficiate IECEx SIR 18.0076X: | Ex ib [ia Ga] IIB 142°C (T3) Gb |

| Ta = -30º to 85ºC |

What others are saying

There are no contributions yet.