In a world where workplace safety is paramount, we, the Intrinsically Safe Store, rise as your fearless ally in the face of danger.

Join us as we unravel the intricacies of Class 1 Division 2, delving deep into its conditions and requirements. This article is your passport to understanding the significance of this classification in hazardous area environments.

Whether you’re a safety professional, a diligent facility manager, or an industry expert seeking to safeguard lives, this comprehensive guide is tailored to equip you with invaluable insights.

Through our years of experience, we have come to understand the diverse needs of individuals in this field, from beginners taking their first steps to seasoned professionals.

We know that choosing the right safety equipment is crucial, and that’s why we’re here to demystify hazardous area classifications, groups, and requirements that underpin Class 1 Division 2.

Our focus is on equipping you with the knowledge and understanding to maximize safety in hazardous environments.

From identifying potential hazards to navigating safety regulations, this comprehensive guide is your trusted companion, empowering you to enhance workplace safety within Class 1 Division 2.

We’re here to make safety accessible and uncomplicated, so join us as we unravel the secrets, answer your burning questions, and pave the way for a secure tomorrow as we learn:

- The purpose and significance of Class 1 Division 2 hazardous area classification in ensuring workplace safety in hazardous environments.

- The specific conditions and requirements associated with Class 1 Division 2 and their implications for equipment selection and installation.

- The importance of compliance with safety regulations and standards in Class 1 Division 2 environments.

- A showcase of workplace safety products, such as safety cameras, hazardous environment lighting, intrinsically safe mobile devices, and explosion-proof fans, that align with Class 1 Division 2 conditions and requirements.

By exploring specific conditions and requirements, you will gain valuable insights into compliance with safety regulations. So, let’s get started.

Understanding Class 1 Division 2: Ensuring Safety in Hazardous Environments

Class 1 Division 2 is a critical hazardous area classification vital to maintaining workplace safety.

It specifically addresses environments where the potential for flammable gases, vapors, or combustible dust exists, although it is not likely to occur under normal operating conditions.

Compliance with Class 1 Division 2 regulations is essential for safety professionals, facility managers, and industry experts to mitigate the risks associated with potential ignition sources.

By comprehending the specifics of Class 1 Division 2, including the criteria for equipment selection, installation, and maintenance, stakeholders can ensure proper implementation of safety measures and select reliable, intrinsically safe equipment.

This classification sets forth regulations and principles governing equipment selection, installation, and maintenance, ultimately fostering a secure working environment.

At our company, we recognize the importance of ensuring that our clients fully comprehend the products they are purchasing.

That’s why we have a team of experts who are readily available to offer guidance and assistance in determining the most suitable equipment for their specific workplace requirements.

We understand that some of our clients may not possess expertise in hazardous area classification or workplace safety products.

Take, for instance, a site administrator involved in procurement, working on a specification without comprehensive knowledge of hazardous area classifications. The client may require simplified explanations and guidance.

Our team of experts is well-equipped to bridge this knowledge gap, ensuring our clients make informed decisions based on their unique needs.

Myth vs Fact: Myth: Class 1 Division 2 regulations only apply to industries dealing with flammable gases. Fact: These regulations apply wherever there’s a potential for flammable gases, vapors, or combustible dust, regardless of the industry.

Unveiling the Hazardscape: Shedding Light on Hazardous Conditions and Environmental Factors

Ensuring workplace safety in hazardous environments requires a comprehensive understanding of the specific conditions and environmental factors that pose potential risks.

By identifying these hazardous conditions and evaluating environmental factors, safety professionals can make informed decisions regarding the selection of Class 1 Division 2 equipment.

Let’s explore the key aspects of hazardous conditions and environmental factors for a safer workplace.

1 – Flammable Gases and Vapor

Recognizing the presence of flammable gasses and vapors is essential, as they can create an explosive atmosphere.

Understanding the potential sources of these substances and their concentration levels is crucial for selecting appropriate safety measures.

Learn More: What does explosion proof mean?

2 – Combustible Dust

In industries such as manufacturing and mining, the presence of combustible dust can pose significant risks.

Proper identification of combustible dust sources and evaluating their potential for ignition is vital for implementing effective safety protocols.

3 – Environmental Hazards

Factors such as temperature variations, humidity levels, corrosive substances, and confined spaces can impact equipment performance and safety.

Considering these environmental hazards ensures the durability and reliability of Class 1 Division 2 equipment.

Intrinsically Safe Store’s range of products is specifically designed to withstand hazardous conditions and environmental challenges. These safety products include:

- Intrinsically safe cameras

- Explosion-proof lighting solutions

- Intrinsically safe mobile devices

- Explosion-proof fans

Our mission is to offer you a range of products that not only deliver reliability but also ensure compliance, empowering you to uphold workplace safety in hazardous environments.

The table below illustrates how different environmental factors can impact equipment and suggests appropriate Class 1 Division 2 equipment for these conditions.

| Environmental Factor | Potential Impact On Equipment | Appropriate Class 1 Division 2 Equipment |

| Temperature Variations | Extreme temperatures can affect equipment performance and lifespan

Overheating may cause malfunctions, while extreme cold could lead to component breakage |

Explosion-proof fans (for cooling in high temperatures), intrinsically safe mobile devices with robust temperature ranges |

| Humidity Levels | High levels of humidity can cause corrosion and equipment degradation, affecting longevity and functionality | Explosion-proof lighting solutions with moisture-resistant designs, intrinsically safe cameras with water-resistant properties |

| Corrosive Substances | Corrosive substances can cause rapid degradation of equipment materials, leading to failures or potential safety hazards | Intrinsically safe mobile devices with corrosion-resistant materials, explosion-proof lighting solutions designed to resist corrosion |

| Confined Spaces | Equipment used in confined spaces may need to withstand extra pressure and restricted airflow

In addition, it must have certain safety properties to prevent accidents like explosions |

All equipment used in confined spaces must be explosion-proof

This includes intrinsically safe cameras, lighting solutions, mobile devices, and fans |

By addressing these hazardous conditions and environmental factors, safety professionals can enhance their safety protocols and protect workers from potential risks in Class 1 Division 2 environments.

Temperature Range and Limitations: Selecting Equipment That Thrives in Challenging Environments

In hazardous environments, temperature variations can pose significant challenges to equipment reliability and safety.

Within hazardous environments, temperature fluctuations can present formidable obstacles to equipment reliability and overall workplace safety.

Understanding the temperature range and limitations of Class 1 Division 2 equipment is crucial for selecting the right products that can withstand extreme conditions and ensure workplace safety.

Here’s a breakdown of what you need to know:

1 – Temperature Classification

Class 1 Division 2 equipment is designed to operate within specific temperature ranges, classified as T1 to T6.

Each classification indicates the maximum surface temperature the equipment can reach during normal operation.

2 – Equipment Selection Considerations

When choosing Class 1 Division 2 equipment, consider the temperature limitations based on your specific environment.

Factors to consider include the following:

- Ambient temperature

- Heat generated by nearby equipment

- Potential temperature spikes during abnormal conditions

It is imperative to consider the range of temperatures the equipment will encounter during its operation and ensure that it falls within the prescribed limits to prevent malfunctions or safety risks.

3 – Intrinsically Safe Store Solutions

Intrinsically Safe Store offers a wide range of temperature-rated safety products covering areas such as:

- Mobility

- Detection

- Measurement

- Lighting

These products are designed and tested to meet the temperature requirements of Class 1 Division 2 environments, ensuring reliable performance even in extreme temperatures.

Understanding the interplay between temperature and these factors is essential for selecting equipment that can withstand the specific environmental conditions of your workplace.

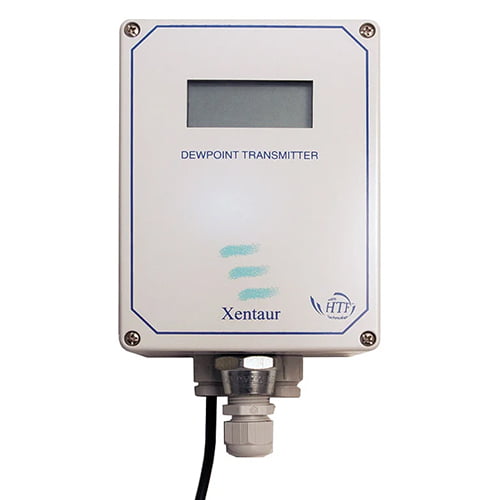

The table below highlights some of Intrinsically Safe Store’s measurement and calibration equipment for Class 1 Division 2 rating.

|

|

|

“Fantastic range, very happy.” — John, Verified Buyer

4 – Heat Dissipation

Adequate heat dissipation mechanisms are crucial for equipment operating in hazardous environments.

Efficient cooling systems, thermal insulation, and heat-resistant materials are essential features to consider when selecting equipment that can thrive in challenging temperature conditions.

At Intrinsically Safe Store, we pride ourselves on offering equipment that thrives in any hazardous environment, even in the face of extreme temperatures.

Take, for instance, our remarkable explosion-proof enclosures.

These enclosures serve a vital purpose in protecting the surrounding environment by containing sparks or explosions within their robust confines.

But they don’t stop there. Our Class 1 Division 2 enclosures are built to withstand scorching heat with unwavering resilience. They are designed to be highly heat resistant, ensuring that fires cannot escape the barrier and pose a threat to the external surroundings.

Our flameproof casings provide a formidable safety measure, preventing malfunctioning equipment from generating sparks that could ignite flammable gases in hazardous environments.

Certification Standards and Compliance: Ensuring Safety in Hazardous Environments

To maintain a safe workplace in hazardous environments, it is crucial to understand and adhere to the certification standards and compliance requirements associated with Class 1 Division 2 equipment.

Compliance with these regulations not only ensures the safety of personnel but also mitigates the risk of potential accidents or incidents.

Intrinsically Safe Store prioritizes safety and compliance, offering products that meet the rigorous certification standards for Class 1 Division 2 environments. These standards are established to ensure the reliability and suitability of equipment in hazardous areas.

By selecting compliant products, safety professionals and facility managers can enhance workplace safety, minimize the risk of ignition, and create a hazard-free environment.

When choosing Class 1 Division 2 equipment, it is also essential to consider the following factors.

Factor 1 – Relevant Safety Regulations

Familiarize yourself with the applicable safety regulations and standards for hazardous area classifications.

Ensure that the equipment you select complies with these regulations to meet safety requirements.

Factor 2 – Certification Compliance

Verify that the products you choose are certified as Class 1 Division 2 compliant.

It is imperative to verify that the products you choose are certified as Class 1 Division 2 compliant, as this provides a seal of approval and validates their suitability for use in these high-risk environments.

Here’s why certification compliance matters:

Assurance of Safety

Certified products provide assurance that they have undergone rigorous testing and meet the necessary standards for safe operation in hazardous locations.

Recognition and Acceptance

Look for recognized certifications, such as UL Listing, ATEX, and IECEx, which validate the equipment’s compliance with safety standards for use in explosive atmospheres.

Regulatory Compliance

Certifications ensure that the equipment meets the requirements set by regulatory bodies like OSHA, helping you maintain workplace safety and avoid potential penalties.

Factor 3 – Intrinsically Safe Store’s Compliance

When selecting equipment for hazardous environments, you can rely on Intrinsically Safe Store for meticulously designed and thoroughly tested products to meet the stringent requirements of Class 1 Division 2.

Our unwavering commitment to compliance ensures that our equipment is safe, reliable, and suitable for use in hazardous areas.

Here’s an example that highlights our dedication to compliance:

Our range of intrinsically safe phones. These devices are purpose-built with hazardous area situations in mind.

When you come across cell phones and smartphones in explosion-proof areas, you’ll find specific certifications displayed, including ATEX Zone 1, ATEX Zone 2, Class 1 Division 1, Class 1 Division 2, IECEx, and others.

The Ecom Smart Ex-02, in particular, stands as the world’s first intrinsically safe smartphone that complies with Google’s rigorous Android Enterprise Recommended (AER) approval for Zone 1/21 and Div.

Additionally, it satisfies all significant international regulatory and hazardous location approvals.

“Easy to use, no complicated buttons and super fast connectivity.” — Offshore RigMan88, Verified Buyer

By prioritizing certification standards and compliance, safety professionals and facility managers

can maximize workplace safety and create a secure environment in hazardous locations.

Durability, Reliability, and Maintenance: Ensuring Long-Lasting Performance in Hazardous Environments

In hazardous environments, where workplace safety is of utmost importance, it is crucial to select equipment that exhibits exceptional durability, reliability, and ease of maintenance.

Class 1 Division 2 environments demand robust solutions that can withstand harsh conditions and provide reliable performance consistently.

Intrinsically Safe Store recognizes the significance of these factors and offers a range of products designed to meet the demanding requirements of hazardous environments.

Our products are engineered with durability in mind, constructed from high-quality materials that can withstand extreme temperatures, corrosive substances, and rugged handling.

With a focus on reliability, our equipment undergoes stringent testing to ensure consistent performance even in challenging conditions.

Furthermore, we understand the importance of proper maintenance to maximize the lifespan and performance of your equipment.

That’s why we provide comprehensive maintenance guidelines and support services to help you maintain your Intrinsically Safe Store products, ensuring they continue to deliver optimal safety and performance in hazardous environments.

Key Takeaway: Intrinsically Safe Store offers durable, reliable, and easy-to-maintain products engineered for hazardous Class 1 Division 2 environments, ensuring optimal safety and performance with comprehensive maintenance support.

Intrinsically Safe Store’s Product Showcase: Reliable Solutions for Class 1 Division 2 Hazardous Environments

At Intrinsically Safe Store, we understand the importance of providing reliable and compliant equipment for Class 1 Division 2 hazardous environments.

Our extensive range of intrinsically safe products is designed to meet the specific conditions and requirements of Class 1 Division 2, ensuring the utmost safety for your workplace.

Now that you have understood the conditions and requirements of Class 1 Division 2, let’s delve into two remarkable examples from our exceptional selection of industry-leading safety products designed for hazardous environments.

These examples will provide you with a better understanding of the types of products available at our store.

Class 1 Division 2 Lighting: Illuminating the Path to Safety in Hazardous Environments

In facilities where there is a potential fire or explosion hazard due to the presence of flammable liquids or gases, Class 1 Division 2 lighting is essential.

The construction of lighting fixtures is governed by the standard UL 844 and the National Electric Code (NEC) article 501, ensuring their safe operation in hazardous classified environments.

One outstanding product in our inventory is the James Industry EX A Series Explosion Proof Lights.

It is approved for use in ATEX Zone 1/21, Class I Division II, Class II Division I, and Class II Division II hazardous sites. With additional certifications from IECEx and marine authorities, this luminaire offers versatile application possibilities.

“It’s so bright and intrinsically safe, it’s perfect for dangerous environments.” — Archeal, Verified Buyer

Whether you need a spotlight, downlight, tunnel light, floodlight, or wall pack, the intrinsically safe luminaire is a reliable choice for illuminating hazardous locations.

Class 1 Division 2 Intrinsically Safe Phone Cases: Ensuring Communication Reliability in Hazardous Environments

In hazardous environments, having reliable communication devices is of utmost importance. That’s why our selection includes a range of intrinsically safe phones and cases specifically designed to withstand the challenging conditions found in hazardous areas.

For instance, we offer the Xciel Samsung Galaxy S21 Case, an intrinsically safe phone case that provides full-body protection and is engineered to withstand the rigors of hazardous environments.

This case is reinforced with sturdy corners and boasts a fully-rugged design, ensuring excellent drop and scratch protection. Moreover, it is lightweight and easy to install, allowing for seamless integration with your Samsung Galaxy S21 device.

The case is certified to meet the stringent safety requirements of ATEX Zone 2 and Class 1 Division 2. This means that it has undergone rigorous testing to ensure its suitability for use in potentially explosive atmospheres.

With our high-quality products, you can confidently enhance workplace safety and maintain compliance with safety regulations.

Our commitment to excellence extends beyond product quality, as we offer expert guidance and exceptional customer service to assist you in selecting the right solutions for your specific needs.

Trust Intrinsically Safe Store to deliver reliable products that provide peace of mind and contribute to a safe working environment in hazardous areas.

Enhancing Workplace Safety With Class 1 Division 2 Equipment

In hazardous environments, the safety of your workforce should never be compromised. Understanding the conditions and requirements of Class 1 Division 2 is essential for creating a secure working environment.

At Intrinsically Safe Store, we offer a comprehensive range of products specifically designed for Class 1 Division 2 environments.

From safety cameras and hazardous environment lighting to intrinsically safe mobile devices and explosion-proof fans, our showcase exemplifies our unwavering commitment to workplace safety.

By choosing Intrinsically Safe Store’s products, you can rely on reliable and compliant solutions that uphold the highest standards of industrial safety.

Our team of experts is ready to assist you in selecting the right equipment for your specific needs, ensuring optimal protection for your personnel.

Prioritize workplace safety today and take the first step towards a secure work environment.

Trust in the expertise and quality of Intrinsically Safe Store for all your Class 1 Division 2 equipment needs. Our mission is to power the world with 10 million hazardous area certified solutions.

Contact us to explore our extensive range of custom safety solutions and make workplace safety your top priority.