Exhaust fans and fans are essential in factories or industries that work with flammable materials. Keeping equipment cool and the atmosphere under control reduces the risk of fire accidents. But, operations with explosion-proof fans are necessary under what circumstances?

A regular fan or exhaust in contact with an atmosphere with flammable material can generate a spark due to the accumulation of these materials in its electrical connections, and any spark trigger is enough for ignition. So how can you prevent accidents like this? This article will help you understand your needs.

What do you need to know about Explosion-proof Equipment

In explosion risk areas, working with proof equipment is essential. Operating in locations where there is a risk of exposure to combustible materials requires twice as much safety. Explosion-proof equipment prevents and resists flammable accidents. If your work presents this risk, you certainly want to make sure your equipment and staff are safe.

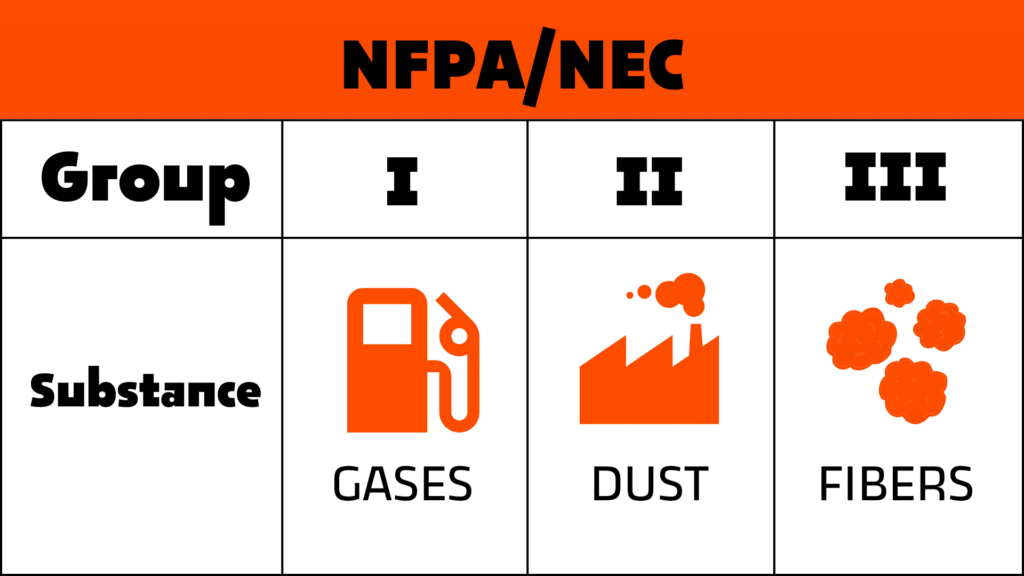

Ex-Proof has certifications and ratings that allow its use in hazardous locations. Let’s take a quick look at which certifications you should consider to ensure your equipment is safe. The international area classification standard helps identify the hazard present in the environment. In the table below, you can check the NFPA and NEC classifications.

In addition to this brief exemplification, the groups are also classified according to the place’s substances. We’ve written in detail about this rating before you can check it out here. Having equipment certified to these regulations gives you confidence that your performance will be productive. To be explosion-proof, the equipment design is to prevent heat or ignition. Therefore, it is essential to consider all the manufacturer’s recommendations for use.

AMCA Designations

Now that you know what to expect from explosion-proof equipment let’s delve deeper into our conversation about Ex-proof Fans and Exhaust Fans. In addition to preventing explosions added to the environment, the fan classified as Ex-proof resists explosions even when it originates from itself.

To have this great function, the design of the fan follows AMCA (Air Movement and Control Association International) standards to minimize the risks of internal sparks. The AMCA standard works with three spark-resistant design designations: A, B, and C types.

Equipment that meets these standards is effective against explosion hazards. As mentioned before, NEC (National Electrical Code) and NFPA (National Fire Protection Association) classifications are also safety and quality references for explosion-proof equipment.

Designed for your Needs

Your primary need is to keep your equipment working safely. Ex-proof exhausts and fans are ideal for industrial areas that contain combustible materials in the air. Also, having the spark protection factor that the AMCA construction standard implements in fans guarantees productivity.

Keeping safety in your workplace is your priority, for sure, you will agree then that to ensure your productivity the best choice are Ex-proof exhausters fans and fans. Searching for the right equipment can be difficult, but we provide you with the best options in Intrinsically Safe Store Catalogue. Count on our experts to give you all the information you need!

In addition to providing some information about explosion-proof equipment, we also recommend that you consult hazardous area engineers to provide you with the equipment that best fits your situation. This booklet can also have more details about hazard location classifications.