ATEX Zone 0 Gas Detector

Showing all 8 resultsSorted by popularity

-

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23c3520c%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-.52253%20106.48691%20-53.3532%20-.2618%20125.3%20119.2)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22222%22%20cy%3D%22152%22%20rx%3D%2246%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-37.13142%20.36088%20-2.4782%20-254.98796%2025%20138.7)%22%2F%3E%3Cellipse%20fill%3D%22%23955529%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(29.1563%20-1.12007%201.60906%2041.88493%20122.5%2077)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

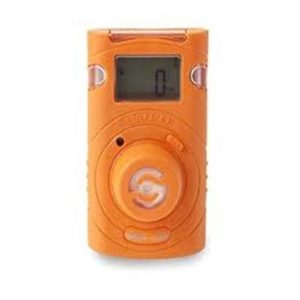

SENKO SGT Portable Gas Detector

$41293Price Depends on product option Make a selection to update priceImport tariffs charged -

%22%20transform%3D%22translate(.9%20.9)%20scale(1.74219)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23b07700%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-53.86295%20-.20023%20.36901%20-99.26568%2079.2%20128)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-24.71268%20-.07972%20.5516%20-170.99911%20157.1%20138)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(158.66908%20-1.3907%20.217%2024.75863%2047.7%2012.4)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cy%3D%22166%22%20rx%3D%2223%22%20ry%3D%22171%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

SENKO SGT- P Replaceable Single-Gas Detector

$18802Price Depends on product option Make a selection to update priceImport tariffs charged -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23c2604e%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(6.10014%20-205.53508%2049.80764%201.47826%20145.3%20255.6)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M376%20474.3l-128.6%2011.3L206%2010.3%20334.5-1z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(92.3%20-101%20131)%20scale(297.50395%2049.19004)%22%2F%3E%3Cellipse%20fill%3D%22%23ff935d%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(5.04974%20-90.54234%2051.40768%202.86712%20147.3%20363.6)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Ion Science TIGER XT Handheld VOC Gas Detector

$9,09360Price Depends on product option Make a selection to update priceImport tariffs charged -

%22%20transform%3D%22translate(.5%20.5)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23170e1f%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(93.4%20-44%20142.3)%20scale(43.06166%2072.13911)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-195.5895%2012.67864%20-2.13233%20-32.89487%2088.1%2021)%22%2F%3E%3Cellipse%20fill%3D%22%23f3f8f3%22%20cx%3D%22189%22%20cy%3D%22143%22%20rx%3D%2214%22%20ry%3D%22196%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-29.59017%20-18.55693%2096.17557%20-153.3579%2024.4%208)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Ion Science Cub 10.6 eV Personal VOC Detector

$2,19000Price Depends on product option Make a selection to update priceImport tariffs charged -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-18.05462%20-87.18245%2057.82462%20-11.9749%20268.2%20264.6)%22%2F%3E%3Cellipse%20fill%3D%22%23d4d4d5%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-2.40716%2022.52438%20-164.69135%20-17.60043%20280.7%2020.1)%22%2F%3E%3Cellipse%20fill%3D%22%23dbdbdc%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-23.01492%2023.62305%20-121.93474%20-118.79579%2024.3%20296)%22%2F%3E%3Cpath%20fill-opacity%3D%22.5%22%20d%3D%22M-4.7-21.5L50-11.8%2018%20169.4l-54.5-9.6z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Ion Science Tiger Fire Investigation Gas Detector Kit

$5,19944Price Depends on product option Make a selection to update priceImport tariffs charged -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23c3520c%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-.52253%20106.48691%20-53.3532%20-.2618%20125.3%20119.2)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22222%22%20cy%3D%22152%22%20rx%3D%2246%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-37.13142%20.36088%20-2.4782%20-254.98796%2025%20138.7)%22%2F%3E%3Cellipse%20fill%3D%22%23955529%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(29.1563%20-1.12007%201.60906%2041.88493%20122.5%2077)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

SENKO iGas Detector CO2

$64798Import tariffs charged -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23c05e14%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-46.22748%204.7517%20-7.55904%20-73.53903%20124%20100.4)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20d%3D%22M174.3%20221l8.5-244%20111%204-8.6%20243.8z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%2225%22%20cy%3D%22125%22%20rx%3D%2243%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%238e5525%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-4.3182%20-25.93673%2023.67018%20-3.94085%20124.1%2071.4)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

SENKO MGT Portable Multi Gas Detector

$71257Price Depends on product option Make a selection to update priceImport tariffs charged -

%22%20transform%3D%22translate(1.7%201.7)%20scale(3.4336)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23d37685%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(103.8%20-55%20101.2)%20scale(86%2016.73886)%22%2F%3E%3Cellipse%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-46.5407%2072.31848%20-32.5968%20-20.97774%2011.7%2043.4)%22%2F%3E%3Cellipse%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(6.4%20-1838.8%20866.7)%20scale(33.54622%2079.15338)%22%2F%3E%3Cellipse%20fill%3D%22%23696068%22%20cx%3D%2242%22%20cy%3D%22104%22%20rx%3D%2221%22%20ry%3D%2238%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Ion Science Tiger Select Portable Benzene Gas Detector

$8,66916Price Depends on product option Make a selection to update priceImport tariffs charged

- ATEX Zone 0 Gas Detectors are critical in preventing accidents in hazardous environments by offering continuous monitoring and early warning of gas presence.

- Technological advancements in these detectors, such as high sensitivity, wireless communication, and smart diagnostics, enhance safety measures and operational efficiency.

- Proper installation and maintenance by professionals are essential to ensure the effective functioning of ATEX Zone 0 Gas Detectors, safeguarding personnel and assets in explosive atmospheres.

ATEX Zone 0 Gas Detector

In industries where safety cannot be compromised, having the right equipment is not just a necessity; it’s a pivotal aspect of daily operations. Among the critical tools in hazardous environments are gas detectors, specifically designed to prevent accidents and ensure the safety of personnel. The ATEX Zone 0 Gas Detector stands out as a premier choice for professionals and organizations operating in some of the most dangerous environments, such as petrochemical complexes and underground mines. Understanding the capabilities and specifications of the ATEX Zone 0 Gas Detector is essential for those seeking to maintain the highest safety standards and comply with strict regulations.

At Intrinsically Safe Store, we are committed to providing our customers with the most reliable and effective safety gear and equipment. Recognizing the significant role that gas detectors play in preventing accidents, we offer in-depth insights into the ATEX Zone 0 Gas Detector. This article aims to educate and inform industry professionals about the features, benefits, and applications of this crucial equipment, empowering them to make informed decisions and maintain a safe working environment. As experts in intrinsically safe and explosion-proof equipment, our goal is to ensure that every organization has access to the knowledge and tools needed to operate safely and efficiently in hazardous areas.

Essential Features of ATEX Zone 0 Gas Detectors

ATEX Zone 0 Gas Detectors are specialized safety devices designed for the highest risk areas within hazardous environments, where an explosive atmosphere is continuously present for long periods or frequently. These detectors play a critical role in preventing accidents and ensuring the safety of personnel and equipment by providing early warnings of gas presence. Understanding the essential features of ATEX Zone 0 Gas Detectors helps professionals and organizations in selecting the right equipment for their safety needs.

Intrinsically Safe Design

The foundational feature of an ATEX Zone 0 Gas Detector is its intrinsically safe design, which ensures that the device itself cannot become a source of ignition. This design principle is achieved through limiting the electrical and thermal energy levels emitted by the detector to levels below those that could ignite a specific hazardous atmosphere.

High Sensitivity and Accuracy

Given the critical nature of their application, Zone 0 detectors are engineered for high sensitivity and accuracy. They can detect the presence of flammable gases at very low concentrations, providing an early warning and enabling prompt action to mitigate risks.

Robust and Durable Construction

Operating in the most hazardous environments demands that these gas detectors are not only functionally reliable but also physically robust. They are typically constructed with durable materials that can withstand harsh industrial environments, including extreme temperatures, moisture, dust, and impact.

Certification and Compliance

Certification to the ATEX directive (Atmosphères Explosibles) is a non-negotiable feature, verifying that the gas detector is suitable for use in Zone 0 environments. Compliance with other international standards, such as IECEx, further reinforces the detector’s safety credentials.

Easy Integration and Communication

An effective ATEX Zone 0 Gas Detector should easily integrate with existing safety and monitoring systems. Features such as wireless communication capabilities enable real-time data transmission and centralized monitoring, enhancing the overall safety management within hazardous areas.

User-Friendly Operations

Given the potential for high-stress situations, ease of use becomes a vital feature. Simple operation procedures, clear display interfaces, and minimal maintenance requirements ensure that the device can be effectively managed by personnel, even under challenging conditions.

Long Battery Life and Low Maintenance

The operational effectiveness of gas detectors in Zone 0 areas is partly dependent on their battery life and maintenance needs. Devices designed for long battery life and low maintenance ensure continuous protection and reduce the total cost of ownership.

Customizable Sensor Configurations

Different hazardous environments require detection of various gas types. ATEX Zone 0 Gas Detectors with customizable sensor configurations offer flexibility, allowing for tailored solutions to meet specific monitoring needs.

Selecting an ATEX Zone 0 Gas Detector with these essential features is crucial for organizations operating in high-risk areas. It embodies a proactive approach to safety, aligning with the commitment to prevent accidents and protect employees and assets in hazardous environments.

How ATEX Zone 0 Gas Detectors Enhance Safety

ATEX Zone 0 Gas Detectors are specifically designed to operate in the most hazardous environments, where the presence of flammable gases or vapors poses a constant risk of explosion. The term “ATEX” refers to the European Directive 2014/34/EU, which stands for Atmosphères Explosibles. This directive ensures that equipment used within explosive atmospheres meets stringent safety standards. Zone 0, within this classification, is defined as an area where a hazardous explosive gas atmosphere is present continuously or for long periods.

The importance of utilizing ATEX Zone 0 Gas Detectors in such environments cannot be overstated. These devices provide several layers of safety enhancements that are critical for the protection of personnel and assets:

- Continuous Monitoring: Unlike periodic inspections, these gas detectors constantly monitor the levels of hazardous gases, ensuring immediate detection of dangerous conditions. This continuous surveillance helps in initiating timely measures to prevent accidents.

- Intrinsically Safe Design: ATEX Zone 0 Gas Detectors are intrinsically safe, meaning they are designed not to produce any spark or heat that could ignite the explosive atmosphere, even if an electrical fault occurs. This intrinsic safety feature is paramount in preventing incidents before they arise.

- Compliance with Safety Standards: Employing ATEX-certified equipment in Zone 0 areas is not only a best practice but a legal requirement in many jurisdictions. These standards ensure that the equipment has undergone rigorous testing to work safely within the most explosive environments.

- Early Warning System: By providing real-time data on gas concentrations, these detectors act as an early warning system, allowing for immediate evacuation and mitigation actions to be taken before the levels reach a critical threshold.

- Integration with Safety Protocols: ATEX Zone 0 Gas Detectors can be integrated into wider safety systems, providing centralized monitoring and control. This integration allows for coordinated responses to hazardous situations, such as activating ventilation systems or shutting down operations to contain risks.

In hazardous areas such as petrochemical complexes or underground mining operations, the presence of ATEX Zone 0 Gas Detectors is a cornerstone of a comprehensive safety strategy. These devices not only ensure compliance with stringent safety regulations but also provide peace of mind, knowing that proactive steps are being taken to mitigate the risks of explosive gas atmospheres. As part of the commitment to safety, Intrinsically Safe Store offers a wide range of ATEX-certified equipment, including gas detectors that meet the highest standards of protection for both personnel and infrastructure in explosive atmospheres.

Technological Advances in Gas Detection for Zone 0

The landscape of gas detection in ATEX Zone 0 environments is witnessing rapid technological advances, ensuring higher safety standards and improved operational efficiency. Understanding the technical progression in this area is vital for professionals and organizations operating in hazardous environments, where the presence of explosive gases or vapors is a constant risk.

At the forefront of these advances is the development of more sensitive and faster-acting sensors. Modern ATEX Zone 0 gas detectors are equipped with sensors that can detect even the smallest leak of combustible or toxic gases, significantly reducing the risk of explosion. These sensors not only offer a quicker response time but also have a longer operational life, thereby ensuring reliability over extended periods.

Wireless communication technology has been a game-changer for ATEX Zone 0 gas detectors. This innovation allows for real-time monitoring of gas levels from a safe distance, enabling prompt and informed decision-making in case of gas leaks. Moreover, wireless connectivity facilitates the integration of gas detection systems into broader safety management networks, providing a comprehensive view of environmental conditions in hazardous areas.

Furthermore, the introduction of smart technologies into gas detection equipment is enhancing safety measures. Intelligent gas detectors can now perform self-diagnostics to ensure they are operating correctly and can even predict sensor end-of-life, allowing for maintenance and replacement before a failure could compromise safety. These smart devices can also learn from the environment they are in, adjusting alarm thresholds based on background gas concentrations and reducing false alarms that can lead to unnecessary downtime.

Additionally, the development of portable and wearable gas detectors offers personal protection that complements fixed monitoring systems. These devices ensure that workers in Zone 0 areas are immediately alerted to potential gas exposures, further contributing to creating safer working conditions.

Finally, advancements in battery technology have led to ATEX Zone 0 gas detectors that are not only more powerful but also lighter and with longer battery life, ensuring that safety equipment does not become an additional burden to workers in hazardous areas.

These technological advancements are pivotal in mitigating risks in hazardous environments. As industry standards continue to evolve, the future of gas detection in ATEX Zone 0 areas looks promising, with continued innovation playing a critical role in safeguarding industries and their workers from potential hazards.

Comparison of ATEX Zone 0 Gas Detectors to Other Zones

Understanding the classification of hazardous areas is crucial for professionals in industries such as petrochemical complexes and underground mining, where the potential for explosive atmospheres necessitates the use of specialized equipment. This section aims to elucidate the differences and functionalities among gas detectors suitable for ATEX zones, with a focus on comparing ATEX Zone 0 gas detectors to those certified for Zone 1 and Zone 2 environments.

ATEX Zone 0 environments are defined as areas where an explosive gas atmosphere is present continuously or for long periods. ATEX Zone 0 gas detectors are designed to operate safely within these environments, offering the highest level of protection. These devices are intrinsically safe, meaning they are incapable of producing a spark or sufficient energy that could ignite an explosive atmosphere. Their construction and functionality are closely regulated to ensure they can operate effectively without posing a risk of ignition, even in the most hazardous conditions.

In contrast, ATEX Zone 1 is characterized by areas where an explosive gas atmosphere is likely to occur in normal operation occasionally. Gas detectors certified for use in Zone 1 are also designed to be intrinsically safe but are engineered for environments where the presence of explosive gases is not as constant as in Zone 0. These devices maintain high safety standards, though they are not required to withstand the continuous presence of explosive atmospheres to the same extent as Zone 0 detectors.

ATEX Zone 2 areas are those where an explosive gas atmosphere is not likely to occur in normal operation but, if it does occur, will persist for a short period only. Zone 2 gas detectors are suited for these less hazardous environments. While they still adhere to intrinsically safe design principles, the emphasis is on functioning effectively in situations where an explosive atmosphere is a possibility but not a constant threat. These detectors may not have the same level of robustness and safety features required for Zone 0 or Zone 1 areas but are sufficient for the level of risk associated with Zone 2 environments.

The choice between these detectors depends on a thorough risk assessment of the area in question. ATEX Zone 0 gas detectors represent the pinnacle of safety technology, designed for the most hazardous conditions. Organizations operating in areas with a high risk of explosive gas atmospheres must prioritize the use of such equipment to safeguard against accidents and ensure compliance with safety standards.

The choice between these detectors depends on a thorough risk assessment of the area in question. ATEX Zone 0 gas detectors represent the pinnacle of safety technology, designed for the most hazardous conditions. Organizations operating in areas with a high risk of explosive gas atmospheres must prioritize the use of such equipment to safeguard against accidents and ensure compliance with safety standards.

Intrinsically Safe Store provides a range of ATEX Zone 0 gas detectors, each meticulously selected to meet our stringent safety and quality standards. Our commitment is to offer equipment that not only complies with regulatory requirements but also aligns with our motto to help customers navigate the complexities of maintaining safety in hazardous environments through informed decisions. This comparison underscores the importance of understanding the specific needs of your operation’s environment and choosing a gas detector that is tailored to meet those needs, ensuring safety and compliance in any hazardous area.

A Guide to Installing and Maintaining ATEX Zone 0 Gas Detectors

When achieving optimal safety in hazardous environments is a priority, understanding how to correctly install and maintain ATEX Zone 0 gas detectors is vital. These devices are engineered to operate safely in the most dangerous conditions, where a high risk of explosive atmospheres is present continuously or for long periods. Here we will provide a comprehensive guide on installing and maintaining ATEX Zone 0 gas detectors, ensuring they function effectively to protect your workplace and personnel.

Installation of ATEX Zone 0 Gas Detectors

1. Understanding the Area Classification

Before installation, it’s imperative to understand the specific classification of the hazardous area. ATEX Zone 0 refers to an area in which an explosive gas atmosphere is present continuously or for long periods. Knowing the specific risks allows for the appropriate placement and type of detector.

2. Selecting the Appropriate Gas Detector

Not all gas detectors are created equal. It’s essential to select a detector specifically designed and certified for use in ATEX Zone 0 environments. These detectors will have the necessary protection methods to safely operate in these extremely hazardous conditions.

3. Strategic Placement

Placement is crucial for effective gas detection. Detectors should be installed where gas leaks are most likely to occur, such as near valves, pipelines, or tanks. Consideration should also be given to the potential gas dispersion patterns based on environmental conditions.

4. Professional Installation

Due to the complexities and the high-risk nature of ATEX Zone 0 areas, installation should only be performed by professionals with expertise in hazardous area equipment. This ensures that all safety protocols are followed and the detectors are properly integrated into your safety system.

Maintaining ATEX Zone 0 Gas Detectors

1. Regular Testing and Calibration

Gas detectors require regular testing and calibration to ensure they provide accurate readings. This should be done according to the manufacturer’s recommendations or more frequently if the detectors are exposed to extreme conditions.

2. Visual Inspections

Routine visual inspections can identify issues such as physical damage or obstructions that might affect the detector’s performance. Regular checks also help ensure that the protective housings and barriers are intact.

3. Record Keeping

Maintain detailed records of installation, testing, calibration, and maintenance activities. This documentation is crucial for safety audits and helps in troubleshooting any issues.

4. Professional Maintenance

Similar to installation, maintenance activities should be carried out by professionals trained in handling equipment for hazardous areas. This ensures that all safety protocols are adhered to and that the equipment’s integrity is not compromised.

By following these guidelines for installing and maintaining ATEX Zone 0 gas detectors, facilities can significantly mitigate the risks associated with explosive gases. It is a complex yet crucial part of maintaining safety in industries that operate in hazardous environments. Remember, the key to safety lies not only in the quality of the equipment but also in the knowledge and practices applied in its installation and maintenance.

Conclusion

In the realms of petrochemical complexes, underground mining, and various industrial sectors, where the presence of hazardous atmospheres is a constant, ensuring the utmost safety is paramount. The ATEX Zone 0 Gas Detector stands as a vital component in mitigating risks and safeguarding both the workforce and infrastructure against the potential of explosive gas atmospheres. These detectors, rigorously engineered to meet the strictest of safety standards, embody the principle of prevention, acting as critical sentinels in the most dangerous environments.

Rooted in our commitment to safety, Intrinsically Safe Store provides a selection of the highest quality ATEX Zone 0 Gas Detectors. We believe in empowering our customers with not only the tools but the knowledge to navigate the complexities of hazardous areas. Our array of intrinsically safe and explosion-proof equipment, complemented by an extensive educational resource, ensures that you are well-equipped to make informed decisions tailored to your unique safety needs. Remember, in the endeavor to create a safe working environment, the right equipment is your first line of defense. Choose wisely, choose safety, choose Intrinsically Safe Store.

FAQs for ATEX Zone 0 Gas Detectors

How can I test the functionality of an ATEX Zone 0 Gas Detector?

Testing the functionality of an ATEX Zone 0 Gas Detector typically involves performing a bump test and a calibration check. A bump test exposes the detector to a known concentration of gas to ensure it triggers an alarm and responds appropriately. This should be done before each use to guarantee operational safety. Calibration checks, which may need to be performed less frequently, ensure the detector’s accuracy in measuring gas concentrations.

Can ATEX Zone 0 Gas Detectors communicate with control systems?

Yes, ATEX Zone 0 Gas Detectors can communicate with control systems. Many modern detectors are equipped with digital output capabilities, such as 4-20 mA signals or wireless transmission, allowing them to interface with control panels and safety systems. This integration enhances monitoring capabilities and enables a quick response to hazard detections.

What power sources do ATEX Zone 0 Gas Detectors use?

ATEX Zone 0 Gas Detectors can be powered by various sources, depending on their design and intended use. Common power sources include batteries, either replaceable or rechargeable, for portable units, and direct wiring into a facility’s power supply for fixed systems. Solar power solutions are also available for remote or difficult-to-wire locations, ensuring continuous operation.

Are there wireless ATEX Zone 0 Gas Detectors?

Yes, wireless ATEX Zone 0 Gas Detectors are available. These detectors provide the benefits of reduced installation costs, flexible placement options, and the ability to easily relocate detectors as site conditions change. With advancements in wireless technology, these detectors maintain reliable communication and provide real-time data on gas concentrations to safety personnel.

How often should an ATEX Zone 0 Gas Detector be calibrated?

The frequency of calibration for an ATEX Zone 0 Gas Detector depends on the manufacturer’s recommendations, the device’s usage frequency, and the environment in which it is used. Generally, calibration is recommended every six months to ensure the detector’s accuracy and reliability. However, in environments with high levels of hazardous gases or where the detector is used more frequently, calibration may be needed more often. Checking the manufacturer’s guidance and adhering to industry best practices is crucial for maintaining safety standards.