Explosion-proof equipment gives you peace of mind daily working in a hazardous area. However, even the tiniest spark produced within a hazardous environment can result in immeasurable damage. In this way, working with explosion-proof equipment is not only an investment but also safe. In this post, we separate some reasons to work with explosion-proof equipment and see the benefits and the application scenarios.

Technical specification of explosion-proof equipment

Let’s start by defining what makes equipment explosion-proof. If your equipment bears the UL certification seal, it is ready and approved for use in hazardous environments. However, be careful to use your ex-proof equipment within the designated area classification. To understand how the ratings work, read our previous post: Explosion-Proof Motor: Learn to identify the ratings.

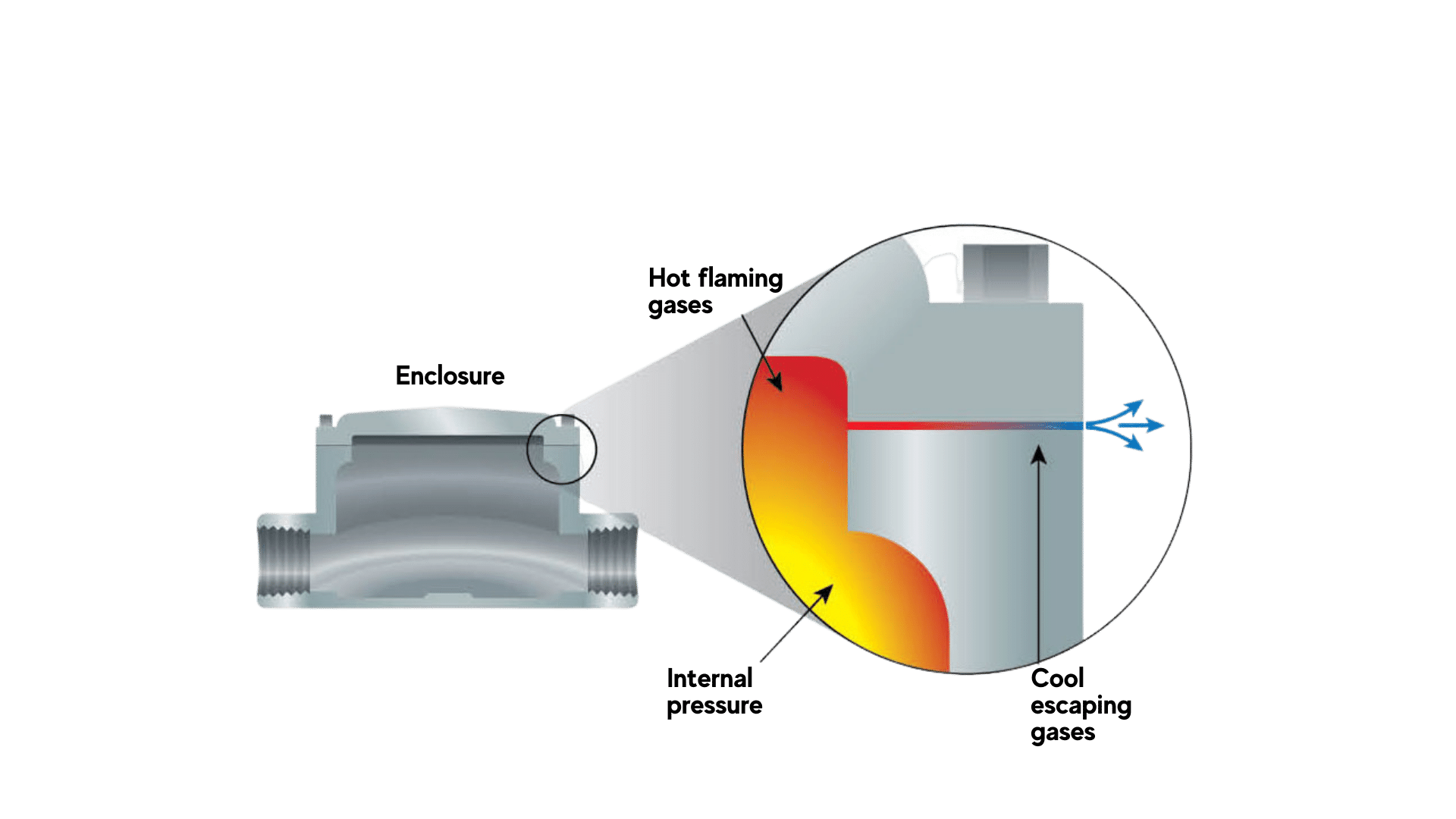

The explosion-proof enclosure acts as a cooler to prevent the explosion from reaching the dangerous atmosphere of the environment. Therefore, regular equipment maintenance will ensure excellent protection in explosive accidents.

In the image above, you see a representation of the cooling done in the explosion-proof housing of the equipment that contains the pressure of gases. Now let’s look at some of the benefits of working with this rugged equipment.

Prevention of potential damage

Using explosion-proof equipment will reduce the risk of more significant damage in your hazardous area. As the equipment is capable of containing internal explosions, this keeps your work area safe and prevents other equipment damage. To visualize this benefit, picture the following scenario. When using an ex-proof motor, a buildup of flammable dust ignites its casing and results in an explosion. However, the case prevents the damage from being greater in the hazardous environment. Thus, in addition to preserving the safety of staff, this safety measure also eliminates the risk of greater financial losses.

Extended shelf life

To deliver durability and strength, the materials used to manufacture explosion-proof equipment must be of the best quality. For example, imagine a junction box for electrical use inside an explosive environment; its material needs to be resistant to contain and cool a possible explosion or fire. In this way, explosion-proof equipment has a longer shelf life, establishing an investment with long-term benefits.

Productivity

Undoubtedly one of your daily goals is to increase productivity in your work routine. Investing in safety measures can increase productivity. With the right equipment, your staff will have less work training for hazardous areas operations. For example, an explosion-proof headlamp becomes very practical for a miner who needs to focus on their service. As a result, they do not commit one of their hands to work and don’t waste the workforce. To further optimize the work, in this case, the installation of explosion-proof light fixtures and the arrangement of portable light also increase productivity in confined environments.

Increase in service value

One of the most significant benefits that the use of explosion-proof equipment can bring is the recognition of a high standard of service. Keeping a hazardous area under control requires investment and knowledge. Training your staff and the right equipment will increase the value and quality of your service and product. Having your efforts recognized in the market is certainly attractive to you! So, put together the best safety strategy using explosion-proof equipment.

Wrap up

In this post, you saw some reasons why integrating explosion-proof equipment in your hazardous area is beneficial. Ensure the safety, quality, and productive growth of your industry. Some of the practical examples mentioned in this article show optimistic scenarios using ex-proof equipment to improve work performance. Those types of equipment make part of our catalog. The Intrinsically Safe Store prioritizes high safety standards, and here you will find the best safety measure. Our intrinsic safety experts will guide you to the best safe control solution for your hazardous area. Do not hesitate to contact us; we are ready for you!