When it comes to industrial safety, one term that often comes up is “intrinsically safe.” But what does this term mean, and why is it so important in industrial settings? In this article, we will delve into the concept of intrinsic safety, its significance, and its application in various industries. This topic is particularly relevant to us at the Intrinsically Safe Store, where we specialize in providing intrinsically safe and explosion-proof equipment. We invite you to explore our website to learn more about our offerings.

Defining “Intrinsically Safe”

Intrinsic safety refers to a design approach used in potentially explosive atmospheres to prevent ignition. This is achieved by ensuring that the energy levels of electrical and thermal equipment are low enough not to cause ignition, even under fault conditions. In other words, explosion-proof equipment is designed to be incapable of releasing sufficient electrical or thermal energy to trigger an explosion.

The Importance of Intrinsic Safety

Intrinsic safety is crucial in industries such as oil and gas, mining, chemical, and pharmaceuticals, where the risk of explosion is high. By using explosion-proof equipment, these industries can significantly reduce the risk of accidents, protecting both their workforce and infrastructure.

Standards and Certifications

Various international standards govern the design and use of explosion-proof equipment. These include the International Electrotechnical Commission (IEC) standards, the European ATEX directive, and the American National Standards Institute (ANSI) standards. Equipment that meets these standards is certified as intrinsically safe, providing assurance of its safety in explosive atmospheres.

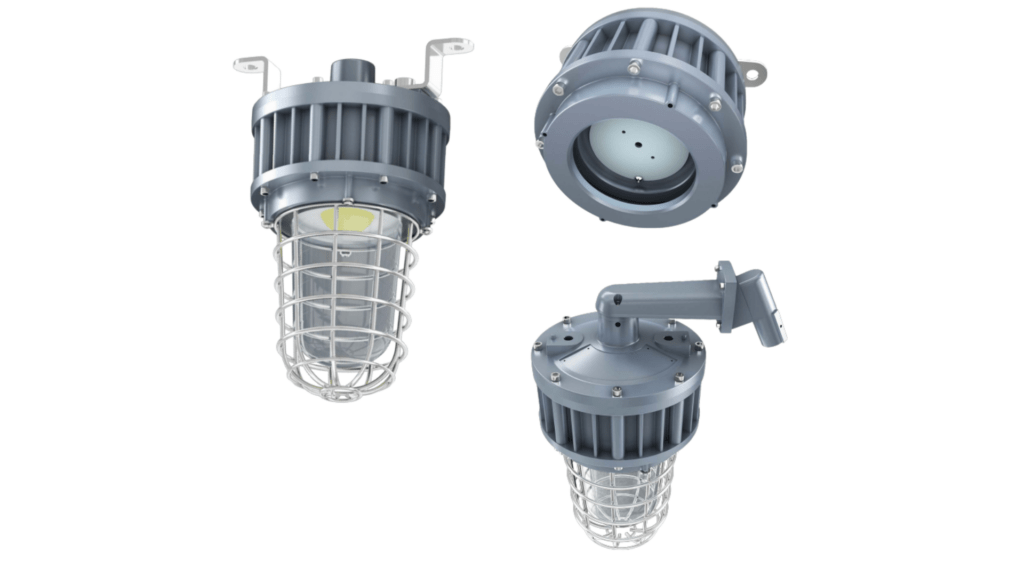

Examples of Intrinsically Safe Equipment

Examples of explosion-proof equipment include sensors, transmitters, and mobile devices designed for use in hazardous areas. These devices are engineered to limit their electrical and thermal energy output, preventing ignition. At the Intrinsically Safe Store, we offer a wide range of such equipment, all certified as explosion-proof.

Case Study: The Use of Explosion-Proof Equipment in the Oil and Gas Industry

A prime example of the application of intrinsic safety is in the oil and gas industry. Here, the risk of explosion is high due to the presence of flammable gases and vapors. By using explosion-proof equipment, the industry can significantly reduce this risk, enhancing safety and productivity.

In conclusion, intrinsic safety is a critical concept in industries where the risk of explosion is high. By limiting the electrical and thermal energy of equipment, intrinsic safety prevents ignition, protecting both people and infrastructure. As a leading provider of intrinsically safe equipment, the Intrinsically Safe Store is committed to promoting safety in hazardous industries. We invite you to contact us to learn more about our offerings and how they can enhance safety in your operations.