Welcome to the Intrinsically Safe Store blog, your go-to resource for all things related to safety in hazardous environments. We are committed to keeping you updated on the latest industry standards and best practices. Today, we delve into the implications of the National Electrical Code (NEC) changes on Class 1 Division 2 operations. We invite you to explore our website for more insights and resources.

Overview of NEC Code Changes

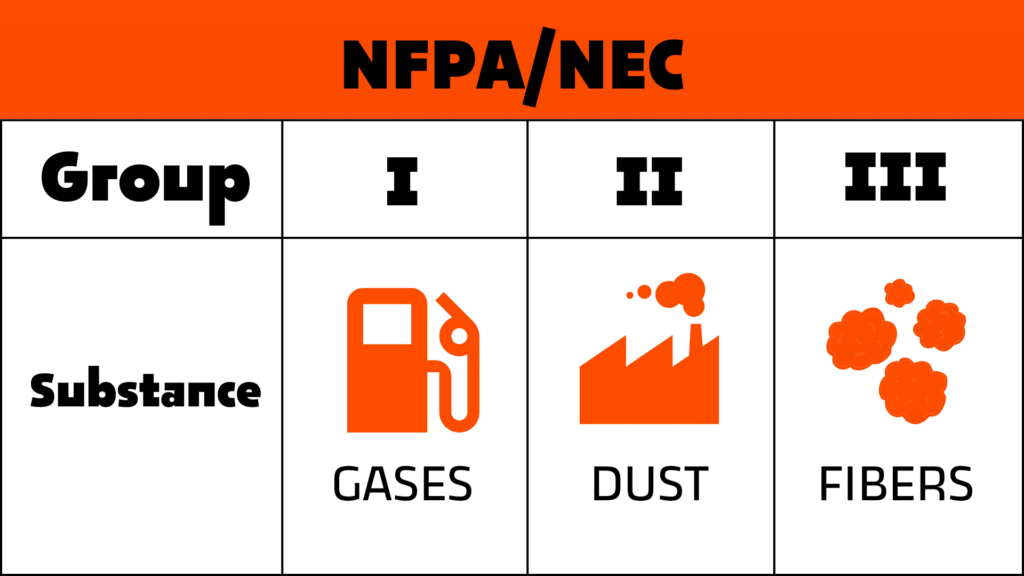

The NEC, also known as NFPA 70, is a set of standards designed to ensure the safe installation of electrical wiring and equipment in the United States. It is updated every three years, with the most recent changes taking effect in 2020. These changes have significant implications for Class 1 Division 2 operations, which involve areas where flammable gases or vapors may be present under abnormal conditions.

Implications of NEC Code Changes on Class 1 Division 2 Operations

The 2020 NEC changes have introduced several new requirements and clarifications that impact Class 1 Division 2 operations. Here are some key takeaways:

- Increased emphasis on safety: The NEC has always prioritized safety, but the 2020 changes take this a step further. For example, there is now a requirement for more extensive use of Ground Fault Circuit Interrupter (GFCI) protection in hazardous locations.

- Clarification on equipment installation: The new code provides clearer guidelines on the installation of equipment in hazardous locations, reducing the risk of non-compliance and potential accidents.

- Expanded use of Informative Annex Q: This annex, which provides guidance on Class 1 Division 2 operations, has been expanded to cover more scenarios, making it a more valuable resource for operators.

Case Study: Impact of NEC Changes on a Chemical Plant

To illustrate the implications of the NEC changes, let’s consider a hypothetical case of a chemical plant. Prior to the 2020 changes, the plant had some areas classified as Class 1 Division 2. However, under the new code, these areas may need to be reclassified and additional safety measures implemented. This could involve installing new GFCI-protected outlets, updating equipment installation practices, and providing additional training for staff. While this may require an upfront investment, it significantly reduces the risk of accidents and non-compliance penalties.

How Intrinsically Safe Store Can Help

At Intrinsically Safe Store, we understand the challenges that come with navigating the complex landscape of safety regulations. We offer a wide range of products and services designed to help you comply with the latest NEC requirements. From intrinsically safe devices to expert consulting services, we have you covered. Visit our website to learn more.

The recent NEC code changes have significant implications for Class 1 Division 2 operations. By understanding these changes and implementing the necessary measures, operators can ensure compliance and enhance safety in their facilities. Remember, staying informed is key to maintaining a safe and compliant operation.

For more information on how to navigate these changes, or to explore our range of intrinsically safe products and services, don’t hesitate to contact us at Intrinsically Safe Store. We’re here to help you navigate the complexities of safety in hazardous environments.