Class 1 Division 1 Fixed Lighting

Explore our premium selection of Class 1 Division 1 fixed lighting, meticulously engineered to ensure safety and reliability in environments with continuous or frequent exposure to hazardous gases and vapors. These lighting solutions are perfect for industries such as oil and gas, chemical processing, and petrochemical facilities.

Show moreOur Class 1 Division 1 lighting fixtures are sourced from top manufacturers and meet the highest safety standards, guaranteeing dependable performance in highly hazardous conditions. Enhance workplace safety, mitigate risks, and ensure compliance with our robust and high-quality fixed lighting solutions designed for these demanding industrial environments.

Showing all 4 results

-

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23818181%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(31.3803%202.00368%20-1.39742%2021.88553%20212.2%2049)%22%2F%3E%3Cellipse%20fill%3D%22%23f6f6f6%22%20cx%3D%22122%22%20cy%3D%2297%22%20rx%3D%22251%22%20ry%3D%2217%22%2F%3E%3Cellipse%20fill%3D%22%23adadad%22%20cx%3D%22117%22%20cy%3D%2251%22%20rx%3D%22255%22%20ry%3D%2224%22%2F%3E%3Cellipse%20fill%3D%22%23f3f3f3%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-254.75382%2011.20238%20-.58516%20-13.30714%20159.9%202.4)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Intrinsically Safe James Industry C Series Explosion Proof Lights

$50000Price Depends on product optionMake a selection to update price -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23a3a3a3%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-7.29113%20-30.60495%2056.0114%20-13.3438%20115.9%2058.1)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M306.4%2065l-4.6%2090.3-320-10.6z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-20.70391%20-23.62507%20154.9449%20-135.78649%20.6%2041.8)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(228.15125%20-58.3364%208.841%2034.57679%20212%20127)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

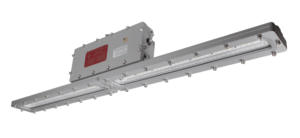

NICOR – XPL1A080U50GR Proteus 80-Watt LED Linear Light

$1,06491 -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(10.87242%2035.7835%20-89.56038%2027.21193%2042.6%2028.8)%22%2F%3E%3Cellipse%20fill%3D%22%23d5d5d5%22%20cx%3D%22128%22%20cy%3D%22112%22%20rx%3D%2275%22%20ry%3D%2275%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-136.8%2051.6%2080.7)%20scale(74.93068%2042.19518)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20d%3D%22M170.8%20246.8l-30.5-57.4%20151-80.2%2030.4%2057.4z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Intrinsically Safe James Industry R Series Explosion Proof Lights

$45400Price Depends on product optionMake a selection to update price -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%238a8a8a%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(109.6%20-1.2%20141.1)%20scale(70.77543%20105.20319)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-13.37007%2059.94374%20-291.66132%20-65.0532%20207%2039.3)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-27.43778%20-.34532%203.76066%20-298.80446%20285%20163.9)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(141.6%20-32.7%20124.4)%20scale(36.65384%20138.7176)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

CRESSA CS-EXHB86-SM Led Explosion Proof Light

$53500Price Depends on product optionMake a selection to update price

- Unmatched Safety: Class 1 Division 1 fixed lighting is crucial for maintaining safety in hazardous environments like the oil and gas industry, preventing potential accidents due to explosions or fires through robust construction and stringent standards.

- Advanced Design: These fixtures are engineered for maximum durability and performance, featuring specialized materials, temperature control, vibration resistance, and effective sealing to withstand harsh conditions.

- Efficiency and Compliance: LED technology in C1D1 lighting offers superior energy efficiency, long lifespan, and improved visibility, ensuring compliance with safety regulations while reducing operational costs and maintenance.

Understanding Class 1 Division 1 Lighting Requirements

When navigating the intricate landscape of lighting in environments where flammable substances are handled, it is imperative to understand the specific requirements that Class 1 Division 1 (C1D1) fixed lighting fixtures must meet. These areas, designated under the National Electric Code (NEC), are where ignitable concentrations of flammable gases, vapors, or liquids can exist under normal operating conditions.

C1D1 fixed lighting fixtures are constructed and tested to operate safely in these hazardous zones, preventing the ignition of the surrounding flammable atmosphere. To comply with this level of safety, C1D1 lighting must adhere to the following standards:

- Construction and Durability: C1D1 lighting fixtures are robustly constructed with high-strength materials that can withstand the harsh environments typically found in the oil and gas sector. They must resist corrosion, vibration, and impacts to ensure they do not become a source of ignition due to a fault or damage.

- Temperature Regulations: The temperatures these fixtures operate at must be considered. They cannot reach temperatures that would ignite the gaseous or liquid substances present in their operating environment. This is known as the fixture’s T-rating, which must not exceed the ignition temperature of the surrounding hazardous atmosphere.

- Sealing and Gasketing: To prevent any entry of the hazardous atmosphere into the lighting fixture, proper sealing and gasketing are critical. The fixtures are often hermetically sealed or potted to ensure no vapor or gas ingress, which could result in an internal explosion.

- Certification: Products used in Class 1 Division 1 areas must be certified by recognized testing laboratories such as UL (Underwriters Laboratories) or ETL (Intertek Testing Services). This certification affirms that the fixtures comply with the stringent requirements needed for safe use in explosive environments.

- Maintenance Considerations: The design of C1D1 lighting often facilitates ease of maintenance because any downtime or need for extensive repairs could prove costly and hazardous. Lighting fixtures in these divisions are designed for longevity and require minimal intervention to sustain their performance.

In the context of the oil and gas industry, it’s not enough to simply choose rugged and durable lighting. Instead, professionals within the industry must select lighting solutions that are designed specifically for the extreme and unpredictable conditions encountered in C1D1 areas. The Intrinsically Safe Store provides fixtures that not only meet the essential safety benchmarks but also ensure optimum performance and minimal maintenance needs.

In the context of the oil and gas industry, it’s not enough to simply choose rugged and durable lighting. Instead, professionals within the industry must select lighting solutions that are designed specifically for the extreme and unpredictable conditions encountered in C1D1 areas. The Intrinsically Safe Store provides fixtures that not only meet the essential safety benchmarks but also ensure optimum performance and minimal maintenance needs.

By adhering to these requirements, oil and gas operations can maintain a safe environment while reducing the risk of accidents related to inadequate or inappropriate lighting in hazardous areas. Equipment from the Intrinsically Safe Store is a testament to a steadfast commitment to safety and operational integrity in some of the most challenging and sensitive work environments.

The Importance of Fixed Lighting in Hazardous Locations

Proper illumination is essential in hazardous work environments such as those found in the oil and gas industry. This need becomes even more critical when considering the stringent safety requirements necessary to prevent accidents and ensure uninterrupted operations. Class 1 Division 1 fixed lighting refers to lighting solutions designed to work in areas where ignitable concentrations of flammable gases, vapors, or liquids are present under normal operating conditions. Such environments require lighting fixtures that are not only durable and reliable but also certified to withstand and prevent potential explosions or fires.

Given the high-risk nature of these sites, fixed lighting plays a critical role in maintaining safety. Good visibility is a fundamental factor for accident prevention and helps in the identification of hazards, execution of tasks, and navigation throughout the facility. Furthermore, these specialized lighting fixtures are engineered to contain any sparks or flames that may result from a fault in the system, preventing ignition of the surrounding atmosphere.

By adhering to the stringent standards prescribed for Class 1 Division 1 locations, fixed lighting solutions ensure that even in the presence of hazardous chemicals or flammable materials, the risk of ignition is mitigated. This not only safeguards the wellbeing of personnel but also protects the infrastructure and assets from damage.

Moreover, the robust construction of Class 1 Division 1 fixed lighting guarantees durability and longevity, reducing the need for frequent maintenance and replacements. This is crucial in minimizing downtime and enhancing efficiency in operations that run round-the-clock. It is therefore imperative for industry professionals to understand the need to invest in lighting systems that meet such high safety standards, ensuring both compliance with regulations and the continuous safe operation of their facilities.

The Intrinsically Safe Store specializes in providing solutions like Class 1 Division 1 fixed lighting that meet these demanding environments, reinforcing its commitment to safety and its value proposition as a single source for any Intrinsically Safe and Explosion Proof certified solutions, tailored for the complexities of the oil and gas sector.

Design Features of Class 1 Division 1 Lighting Fixtures

Class 1 Division 1 lighting fixtures are meticulously designed to guarantee safety and performance in the most volatile environments. These lighting solutions must adhere to the strictest safety standards dictated by regulatory agencies for use in areas where ignitable concentrations of flammable gases, vapors, or liquids are present continuously or for long periods.

Enclosure Integrity

To prevent any possibility of ignition, the enclosure of Class 1 Division 1 lighting is designed for maximum durability and strength. Constructed from robust materials—such as heavy-duty stainless steel, aluminum, or glass-reinforced polyester—these fixtures are engineered to withstand both environmental challenges and potential explosion pressures without compromise.

Gasket Sealing

Every potential point of entry for gases or vapors into the lighting fixture is meticulously sealed. High-quality gaskets, usually made from neoprene or silicone, are used to form a tight seal, preventing the ingress of hazardous substances. This sealing technology is crucial to maintain the integrity of the explosion-proof rating.

Temperature Control

These fixtures are designed to operate safely below the ignition temperature of specific hazardous materials they may come into contact with. Innovative thermal management systems ensure the fixtures remain within safe operating temperatures at all times.

Vibration and Impact Resistance

Given the industrial settings of their application, Class 1 Division 1 lighting fixtures must endure vibration and physical impacts. The design often incorporates vibration-resistant features and heavy-duty mounts to maintain operational stability and prevent damage that could compromise the safety of the fixture.

Light Source Efficiency and Longevity

With the use of LED technology and advanced optics, Class 1 Division 1 lights provide superior illumination and energy efficiency. LEDs are favored not only for their low-heat emission but also for their long life span, reducing the need for frequent maintenance and replacements in difficult-to-access installations.

Ease of Maintenance

Although they are built to last, Class 1 Division 1 fixtures are often designed with maintenance considerations in mind. Easy access points and modular components make inspection and servicing as straightforward as possible, while ensuring that the integrity of the enclosure is maintained post-maintenance.

Certification Marks

All Class 1 Division 1 fixed lighting fixtures display certification marks from nationally recognized testing laboratories (NRTLs) such as UL (Underwriters Laboratories) or ETL (Intertek Testing Services), signaling compliance with the relevant safety standards and reassuring that they have been tested for safe use in designated hazardous environments.

Incorporating these essential design features, Class 1 Division 1 fixed lighting fixtures provide not only reliable and efficient performance but, more importantly, ensure the utmost safety for personnel and infrastructure in the oil and gas industry. The Intrinsically Safe Store remains at the forefront, supplying such critical lighting solutions that fulfill the rigorous demands of these hazardous settings.

Installation Best Practices for Hazard-Proof Lighting

When operating in environments where there is a significant risk of explosions due to the presence of flammable gases or vapors, installing hazard-proof lighting is not just essential—it’s a critical component of maintaining a safe workplace. Class 1 Division 1 (C1D1) fixed lighting is specifically designed to operate safely in such hazardous areas. To ensure optimal safety and functionality, it’s imperative to follow industry best practices during the installation of C1D1 fixed lighting fixtures.

- Understand the Area Classification: Before any installation begins, comprehensively understand the specific hazardous area classification of the workspace. This knowledge will dictate the appropriate type of Class 1 Division 1 fixed lighting that meets the necessary safety requirements and is designed for the right kind of hazard.

- Choose Certified Fixtures: Always select lighting fixtures that carry the necessary certifications and approvals from recognized agencies such as UL (Underwriters Laboratories) or ETL (Intertek Testing Services). These certifications guarantee that the lighting fixtures comply with safety standards suitable for Class 1 Division 1 environments.

- Follow Manufacturer’s Instructions: Adherence to the manufacturer’s installation guidelines is paramount. Every C1D1 fixed lighting fixture will come with detailed instructions concerning mounting, wiring, and any other precautions that need to be taken. Following these to the letter ensures that the integrity and safety of the lighting fixture are maintained.

- Use Sealed and Gasketed Components: Any lighting fixtures and accessories must be sealed and use gaskets where necessary to prevent the ingress of hazardous materials. Check that all junction boxes, conduit connections, and fixture lenses are properly sealed against the surrounding environment.

- Employ Qualified Personnel: Installation should be performed by professionals who are trained and experienced in working with electrical systems in hazardous locations. Qualified electricians with a background in hazardous area installations understand the complexities and safety precautions that are necessary in such settings.

- Prioritize Accessibility for Maintenance: While the installation needs to adhere to safety protocols, it is equally important that it allows for easy access for maintenance and inspection. Positioning the fixtures for straightforward access will ensure that they can be serviced safely and efficiently, leading to reduced downtime.

- Test and Inspect Regularly: After installation, thoroughly test the fixed lighting system to ensure its correct function before the area is put back into service. Regular inspections and maintenance are needed to identify and rectify issues such as wear and tear or environmental damage, which can compromise safety.

By meticulously applying these best practices, industry professionals can ensure that the installation of Class 1 Division 1 fixed lighting in hazardous locations is performed correctly, promoting a high level of safety and operational efficiency in the oil and gas industry.

Comparing LED vs. Traditional Lighting in Hazardous Areas

When it comes to hazardous environments, specifically where Class 1 Division 1 fixed lighting is required, making the right choice between LED and traditional lighting is critical for ensuring both safety and efficiency. In environments such as the oil and gas industry where flammable gases, vapors, or liquids may exist under normal working conditions, lighting must be designed to prevent ignition and withstand extreme conditions.

Traditional Lighting Solutions Historically, hazardous areas have been illuminated by traditional lighting solutions such as High-Intensity Discharge (HID) lamps, including metal halide, high-pressure sodium, and fluorescent lighting. These light sources have been commonly used due to their high luminance and ability to brighten extensive areas. However, they also come with notable drawbacks. Traditional lights have a shorter lifespan, require more maintenance, generate significant heat, and have slower startup and restrike times. Additionally, they are less energy-efficient, which can lead to higher operational costs over time.

Advantages of LED Lighting In contrast, LED (Light Emitting Diode) lighting is gaining widespread acceptance in hazardous areas due to its numerous advantages. The primary benefits of LEDs in environments requiring Class 1 Division 1 fixed lighting include:

- Energy Efficiency: LEDs consume significantly less power than traditional lighting, resulting in lower energy bills and reduced operating costs.

- Longevity: With long-lasting lifespans, LED lights reduce the frequency of replacements and the associated downtime and maintenance costs.

- Durability: Designed to be more robust, LEDs can withstand vibration, impacts, and extreme temperatures better than traditional bulbs.

- Safety: Emitting less heat and being instant-on without a restrike delay, LEDs reduce the risk of accidental ignition in hazardous areas.

- Improved Visibility: LED lighting provides better color rendering and uniform illumination, improving visibility for safer and more efficient operations.

The implementation of LED lighting in hazardous locations not only aligns with The Intrinsically Safe Store’s commitment to safety but also supports operational efficiency and cost-effectiveness. While the initial investment may be higher for LED lighting when compared to traditional options, the long-term savings and safety benefits overwhelmingly justify the decision.

When comparing LED vs. traditional lighting for Class 1 Division 1 fixed lighting applications, it becomes clear that LED technology aligns more closely with the needs of modern hazardous area operations. Industry professionals must weigh both the immediate and long-term impacts of their lighting choices, considering not only the upfront cost but also the implications for safety, maintenance, energy consumption, and total cost of ownership.

When comparing LED vs. traditional lighting for Class 1 Division 1 fixed lighting applications, it becomes clear that LED technology aligns more closely with the needs of modern hazardous area operations. Industry professionals must weigh both the immediate and long-term impacts of their lighting choices, considering not only the upfront cost but also the implications for safety, maintenance, energy consumption, and total cost of ownership.

With these factors in mind, LED lighting stands out as the optimal solution for hazardous locations, particularly in the oil and gas industry, where the right lighting is essential for both productivity and protection. The Intrinsically Safe Store understands these industry needs, providing access to a wide selection of certified Class 1 Division 1 LED lighting solutions that meet the highest standards of safety and efficiency.

FAQs on Class 1 Division 1 Fixed Lighting

What is Class 1 Division 1 fixed lighting?

Class 1 Division 1 fixed lighting refers to the specialized lighting fixtures that are designed for use in hazardous areas where flammable gases, vapors, or liquids are present under normal operating conditions. This type of lighting is engineered to avoid creating sparks or excessive heat that could trigger an explosion. These fixtures are encased within robust, explosion-proof housings to maintain safety in the most volatile environments.

How is Class 1 Division 1 defined?

Class 1 Division 1 is a classification defined by the National Electric Code (NEC) which categorizes specific hazardous locations where ignitable concentrations of flammable gases, vapors, or liquids can exist under normal operating conditions. In such environments, all electrical equipment, including lighting, must meet stringent requirements to prevent ignition of the hazardous atmosphere.

Are explosion-proof lights and Class 1 Division 1 lights the same?

While sometimes used interchangeably, explosion-proof lights and Class 1 Division 1 lights are not necessarily the same. Explosion-proof lights are designed to contain an explosion within their housing and prevent it from igniting the surrounding atmosphere. On the other hand, Class 1 Division 1 lights specifically refer to lights suitable for Class 1 Division 1 locations and are one subtype of explosion-proof lighting. Not all explosion-proof lights are rated for Class 1 Division 1 environments.

How do I know if I need Class 1 Division 1 lighting?

If you are operating within an environment outlined by the NEC as Class 1 Division 1, you must use lighting that meets or exceeds that classification. Locations are typically classified based on the presence of hazardous materials as part of their normal operations, such as in petroleum refineries, dry cleaning plants, or locations where propane, gasoline, methane, or other flammable gases or vapors are handled, processed, or used.

Can Class 1 Division 1 lights be used in a Division 2 area?

Yes, Class 1 Division 1 lights can be used in a Division 2 area. Class 1 Division 2 locations are areas where flammable liquids, gases, or vapors are handled, stored, or processed, but are normally confined within closed containers or systems and will only escape in case of accidental rupture or breakdown. Since Class 1 Division 1 fixtures are designed for more hazardous environments, they also meet the requirements for Division 2 areas. However, using a Division 1 rated light in a Division 2 setting may not always be cost-effective or necessary.