As the world becomes increasingly digital, the need for robust and reliable information systems (IS) is paramount. However, every industry has unique needs and challenges that require tailored solutions. This is where the customization of IS barriers comes into play. In this article, we will delve into the importance of customizing IS barriers for specific industry needs, using real-world examples and case studies. Intrinsically Safe Store, is a leading provider of intrinsically safe products and solutions. We encourage you to visit our website to learn more about our offerings.

Understanding IS Barriers

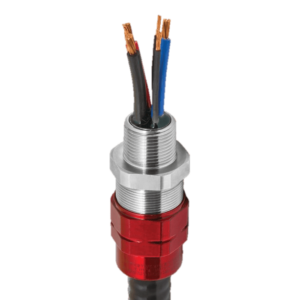

IS barriers are safety measures designed to prevent the accidental ignition of hazardous substances in industrial environments. They are a critical component of any IS, ensuring the safe operation of electronic devices in potentially explosive atmospheres.

The Need for Customization

While IS barriers are essential, not all industries have the same requirements. Factors such as the type of hazardous substances present, the nature of the work being performed, and the specific regulations governing the industry can all influence the type of IS barrier needed. Therefore, customization is key to ensuring that the IS barrier is fit for purpose and can effectively mitigate risks.

Case Study: Oil and Gas Industry

Take the oil and gas industry, for example. This industry is characterized by highly volatile substances, extreme temperatures, and potentially explosive atmospheres. As such, it requires IS barriers that are robust, reliable, and capable of withstanding harsh conditions. Customized IS barriers for this industry might include features such as enhanced temperature resistance, increased explosion protection, and advanced fault detection capabilities.

Case Study: Pharmaceutical Industry

On the other hand, the pharmaceutical industry has different needs. While it also deals with potentially hazardous substances, the focus is more on preventing contamination and ensuring product quality. Therefore, customized IS barriers for this industry might prioritize features such as advanced filtration systems, precise temperature control, and stringent hygiene standards.

Benefits of Customization

Customizing IS barriers for specific industry needs offers several benefits. It ensures the IS barrier perfectly suits the task at hand, enhancing safety and efficiency. This also provides greater flexibility and adaptability, as industry needs change, the IS barrier can be modified or upgraded. Furthermore, it can lead to cost savings in the long run, as it reduces the risk of equipment failure and the associated downtime and repair costs.

Intrinsically Safe Store: Your Partner in Customization

The Intrinsically Safe Store understands the importance of customization. We offer a wide range of intrinsically safe products and solutions, all of which can be tailored to meet your specific industry needs. With our expertise and commitment to quality, you can be confident that your IS barriers will be up to the task.

In conclusion, the customization of IS barriers for specific industry needs is not just a luxury—it’s a necessity. It ensures that your IS barriers are fit for purpose, enhancing safety, efficiency, and cost-effectiveness. Whether you’re in the oil and gas industry, the pharmaceutical industry, or any other industry that deals with hazardous substances, the Intrinsically Safe Store can provide you with the customized IS barriers you need. Don’t hesitate to contact us for more information.