If you come from a water controls background or work in fuels, you will notice that many new designs still use 120VAC controls with heavy and expensive explosion proof boxes for switches, indicators, and buttons.

It is understandable to use this design for high power devices like pumps, but for remote indicators and operator panels, it seems to me intrinsically safe is better in almost every way. A lot of the plans could seem like they could be designed in the 80s.

What am I missing here? Why spend all the effort to explosion proof a switch or light that doesn’t need 120VAC to begin with to send a signal or indicate a condition? Intrinsically safe barriers are far less expensive even the smallest explosion proof boxes I’ve seen. And low voltage DC is generally safer all around.

Intrinsically safe barriers are far less expensive even the smallest explosion proof boxes there are. And low voltage Direct Current (DC) is generally safer all around.

Explanation 1: Usage

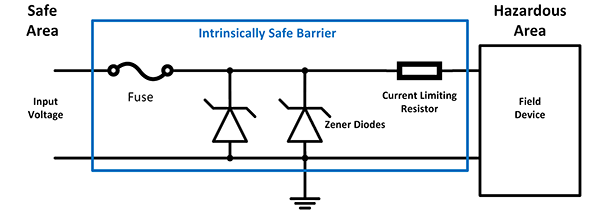

When you pair a safety barrier with a sensor or a small actuator, such as a solenoid on a pneumatic pilot valve, intrinsically safe (IS) solutions can prove to be highly effective and economical, especially when compared to explosion-proof (XP) options.

IS is well-suited for applications where the energy requirements are relatively low. On the other hand, XP is typically necessary for actuators that involve substantial energy.

Both IS and explosion-proof solutions introduce some complexities into the design and installation process, but these challenges are generally manageable.

The cost of sensors in IS housing is often similar to that of sensors in XP housing. One notable advantage of using IS is the ability to employ a “simple device” as defined by the National Electrical Code (NEC) and forgo the need for XP or IS rated devices, provided that an appropriate barrier is used.

However, retrofitting IS systems can be quite challenging due to specific panel design requirements. This complexity arises from the need to ensure that the entire system adheres to the safety and electrical standards associated with IS. This makes it less practical for projects involving pre-existing infrastructure or equipment.

In such cases, transitioning to IS may require substantial modifications to the existing setup, making it a less attractive option for retrofitting.

Explanation 2: Design

Explosion-proof solutions are generally less prone to failure because they primarily involve enclosing the potentially hazardous components within a robust housing.

In essence, explosion-proof housing serves as a protective barrier, making it less likely for internal components to be exposed to hazardous conditions.

This design approach is inherently fail-safe in nature. In the event of a hazardous situation, the explosion-proof housing prevents the release of energy or materials that could lead to an explosion or fire.

Conversely, intrinsically safe (IS) solutions are more focused on preventing ignition sources within the equipment itself. However, they can be more susceptible to failure at various component levels, and these failures might occur more easily compared to the robust housing required for explosion-proof systems.

IS is more of a preventive measure, aiming to reduce the energy levels within the device to levels where ignition is unlikely. It’s worth noting that IS is often used in scenarios where explosion-proof housing is impractical due to cost, size, or other constraints.

So, while explosion-proof solutions are inherently fail-safe due to their protective housing, intrinsically safe systems rely on prevention measures to reduce the risk of ignition, which may introduce more potential points of failure in the system.

Therefore, the design and selection of safety measures should consider the specific requirements and constraints of the application to determine the most suitable approach.

Explanation 3: Costs

In many cases, while intrinsically safe (IS) systems offer advantages in terms of safety and reduced risk, they can indeed be more expensive to design, implement, and maintain.

The need for meticulous design work, specialized components, and adherence to safety standards can drive up the cost of IS systems significantly.

Conversely, investing in an explosion-proof (XP) solution, such as purchasing a higher-cost explosion-proof switch, can often be a cost-effective decision when the alternatives involve extensive design work and additional expenditures.

XP solutions are a straightforward way to address safety concerns, and the up-front investment in XP equipment, like the switch, can save a substantial amount of money by avoiding the need for complex engineering reports, specialized components, and the ongoing costs associated with maintaining and updating IS systems.

In many scenarios, the cost savings provided by using XP solutions can far outweigh the upfront expenditure, making it a practical and cost-effective choice for safety in environments where the risk of explosion or fire is a concern.

Bottom-line

Explosion-proof designs are still widely used over intrinsically safe controls in certain applications because they provide a robust and proven method of containing potential explosions.

This is crucial in environments where the risk of explosive atmospheres cannot be fully eliminated or controlled. These designs are often mandated by regulations and standards in industries with extreme conditions, such as oil and gas, where the safety benefits of explosion-proof enclosures outweigh the higher cost and complexity associated with these systems.

Furthermore, existing infrastructure and legacy systems in many industries favor explosion-proof designs, making the transition to intrinsically safe controls cost-prohibitive in some cases.

Order your Intrinsically Safe or Explosion Proof Equipment Now

In today’s ever-evolving industrial landscape, safety is paramount. Don’t wait for a potential disaster to strike; act now and secure your workplace with the highest level of protection. Order your intrinsically safe or explosion-proof equipment today to safeguard your operations, personnel, and assets.

Our reliable, certified solutions are designed to meet the most rigorous safety standards, ensuring peace of mind and uninterrupted productivity. Embrace the future of industrial safety – act now, and let us be your trusted partner in protecting what matters most.

At Intrinsically Safe Store, we understand the urgency of safety, and that’s why we’re here to help.

Our extensive range of intrinsically safe and explosion-proof equipment is tailored to meet the unique demands of your industry.

Whether you’re in manufacturing, oil and gas, or any other high-risk environment, we’ve got you covered. Ordering is easy and convenient – just a few clicks away.