Welcome to our exploration of explosion-proof lighting, a critical safety measure in hazardous environments. As we delve into its importance, we strongly encourage you to visit IntrinsicallySafeStore.com to explore a wide range of explosion-proof lighting solutions designed to protect workers and prevent accidents. Take charge of your workplace’s safety by equipping it with the protection it deserves.

Understanding Explosion-Proof Lighting

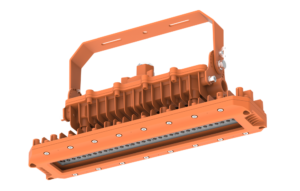

Explosion-proof lighting is not your typical lighting system; it is designed to serve a specific and crucial purpose. This type of lighting is engineered to prevent the ignition of flammable gases, vapors, or dust that may be present in potentially explosive atmospheres. Therefore, lighting isn’t just about illumination; it’s about ensuring safety in environments where the risk of explosions is a constant threat.

Application in Hazardous Industries

Industries such as oil and gas, chemical processing, mining, and manufacturing often operate in conditions where explosive materials are a part of everyday operations. In such environments, any source of ignition, including a spark from a light switch or a hot surface, could trigger an explosion. This is where specialized lighting comes into play. By containing any sparks or heat within the light fixture itself, these systems can prevent these potential ignition sources from coming into contact with the surrounding volatile atmosphere.

Specific Industry Applications

In the oil and gas industry, for example, extraction and refining processes often release flammable gases. To mitigate the risk of igniting these gases, explosion-proof lighting is used in areas where these gases are likely to be present. Similarly, in the chemical processing industry, various processes can release flammable vapors. Here too, explosion-proof lighting can prevent these vapors from igniting.

In mining operations, flammable dust is often a significant concern. Underground mining operations can release methane gas and coal dust, both of which are highly explosive. Lighting in these operations is essential to prevent a devastating ignition.

Manufacturing facilities, especially those dealing with flammable materials or operating in dusty environments, also require explosion-proof lighting. For example, grain processing facilities, where highly explosive grain dust is often present, rely heavily on this type of lighting.

Safety and Protection

Ultimately, the primary aim of specialized lighting is to safeguard the lives of workers in these industries. By mitigating the risk of explosions, these lighting systems help to create a safer working environment. In essence, this lighting serves not just to illuminate but to protect.

Key Features of Explosion-Proof Lighting

- Enclosed Design: Explosion-proof lights feature sturdy enclosures that prevent sparks, arcs, or excessive heat from igniting surrounding hazardous substances.

- Sealed Components: Additionally, critical electrical components are hermetically sealed to prevent the ingress of gases or dust, thereby minimizing the risk of ignition.

- Impact Resistance: Furthermore, these lights withstand impact and vibration, which is crucial in rugged industrial environments where accidents are more likely to occur.

- Temperature Regulation: Moreover, explosion-proof fixtures include mechanisms to dissipate heat efficiently, thereby reducing the risk of overheating and potential ignition sources.

- Certifications: Additionally, compliance with stringent industry standards and certifications ensures the reliability and safety of explosion-proof lighting systems.

Importance in Accident Prevention

- Mitigating Ignition Risks: Firstly, explosion-proof lighting significantly reduces the likelihood of explosions by eliminating potential ignition sources in hazardous environments.

- Enhancing Visibility: Proper illumination is crucial for maintaining a safe working environment. Consequently, explosion-proof lighting ensures adequate visibility, thereby reducing the chances of accidents caused by poor lighting conditions.

- Minimizing Downtime: Additionally, in the event of an explosion, downtime resulting from injuries, damage to equipment, and cleanup can be substantial. Investing in explosion-proof lighting helps mitigate these risks, minimizing downtime and ensuring continuity of operations.

- Compliance with Regulations: Regulatory bodies mandate the use of explosion-proof lighting in hazardous areas to protect workers and prevent catastrophic accidents. By complying with these regulations, organizations not only ensure legal adherence but also reflect a commitment to workplace safety.

In conclusion, prioritizing safety in hazardous environments is paramount. Take action towards creating a safer workplace by contacting us at IntrinsicallySafeStore.com. Our experts stand ready to assist you in selecting the right explosion-proof lighting solutions for your specific needs. Together, let’s illuminate the path to a safer tomorrow.