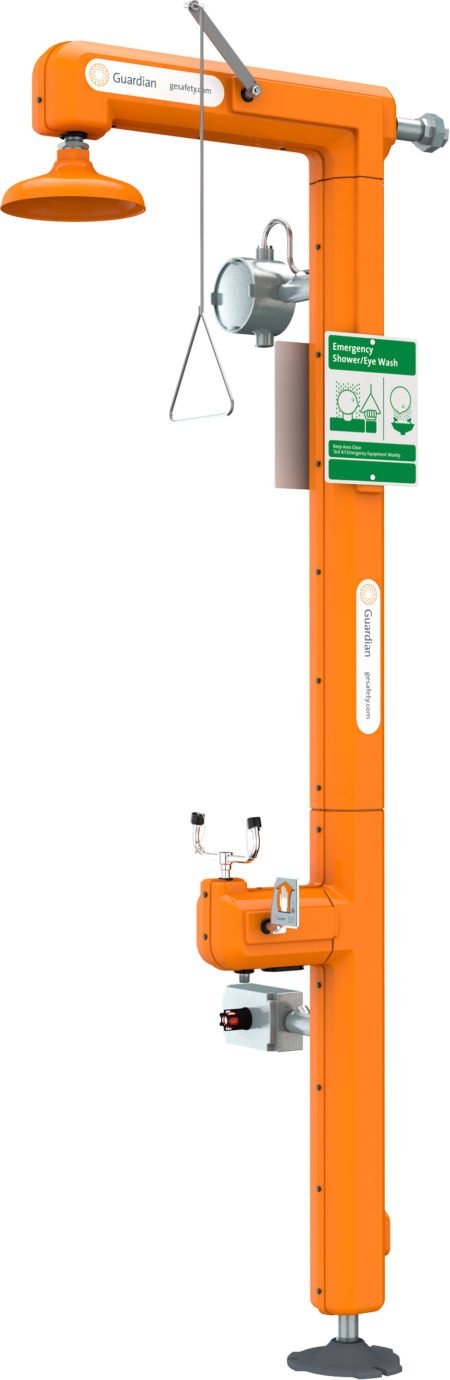

Guardian Equipment introduces the GFR3210 fundamentally safe emergency eyewash station. This heated safety station with top inlet and eyewash is suitable for use in a Class I Division 1 environment.

Features:

- Class I Division 1

- Floor mounted electrically heat traced emergency eyewash station with top inlet

- ABS plastic showerhead with internal 20 GPM flow control

- 1” IPS U.S. made stay-open brass ball valve with stainless steel actuating arm

- ½” IPS U.S. made 3-way self-draining stay-open brass ball valve

- 1¼” IPS Schedule 40 hot dipped galvanized pipe and fittings

- Stainless steel flag handle and powder-coated cast aluminum floor flange

- UV-resistant ABS plastic jacket with foam insulated core and weather sealed with elastomeric material

- 120VAC and 60 HZ single phase power supply

- Pipe sensing thermostat

- Trace indicator light included

Application: Class I, Division 1 rated electric heat-traced stations prevent freezing in extremely hazardous, cold weather conditions where flammable gases are routinely expected. Units that are thermostatically controlled are heated by a self-limiting heat-tracing cable wrapped around an internal pipe. The units are designed for usage in temperatures as low as -40°F. See ‘Tempering Valves’ section to ensure tepid water compliance with ANSI Z358.1-2014.

Heating Cable: Self-regulated with external termination guards. Thermostat activates when internal piping temperature falls below 50°F. FM, UL, and CSA approved for Class I, Division 1, Groups B, C, and D.

Electrical System: Unit is fully wired at factory. Junction box and components rated for Class I, Division 1, Groups B, C, and D. Requires 120 VAC single phase power supply. Heat-trace indicator light included. Note: In order to meet Class I, Division 1 requirements, approved conduit and fittings must be used during installation.

Jacket/Insulation: UV-resistant orange ABS plastic with polyethylene foam insulation. Jacket sections are secured with removable stainless steel screws for easy maintenance.

Shower Head: 10” diameter orange ABS plastic with 20 GPM flow control.

Shower Valve: 1” IPS brass stay-open ball valve. US-made with brass ball and PTFE seals. Includes stainless steel actuating arm and 29” stainless steel pull rod.

Spray Head Assembly: Freeze-resistant with float-off dust covers and internal flow control.

Eyewash Valve: 1/2” IPS brass three-way self-draining stay-open ball valve. US-made with brass ball and PTFE seals. Includes 1/2” NPT port to drain water from spray heads after use.

Pipe And Fittings: Schedule 40 galvanized steel.

Supply: 1-1/4” NPT female top inlet.

Sign: ANSI-compliant identification sign.

Quality Assurance: Factory tested prior to shipment. Ships fully assembled and crated.

Shipping: For this specialized unit, expect lead time to be around 6-7 weeks

Specifications:

| Available Options | |

| SSH | Stainless steel shower head |

| GRN | Green ABS plastic shower head and shell |

| HV | 240 volt heat-tracing |

| TL | Heat-trace indicator light |

| SP | Scald protection valve. |

| FP | Freeze protection valve |

| ALC | Clear Area Light (ships separately from unit) |

| G3800LF Thermostatic mixing valve | Note: Must be installed in a non-freezing environment. |

General Notes

1. Freeze resistant spray head assembly with internal 3.2 GPM flow control and float off dust covers

2. Designed for use in Class 1 Division 1, Groups B, C and D environment

3. Peak heat trace power consumption is 80 watts

4. In order to meet Class 1 Division 1 requirements, approved conduit and fittings must be used. All threaded electrical connections must have hazardous location rated sealant applied to threads.

Other Notes:

Mechanical and electrical connections must be performed prior to installing a heat traced safety station. A licensed plumber and an electrician should perform the installation. All work must adhere to applicable standards, including local plumbing and electrical ordinances, as well as OSHA regulations for electrical equipment lockout. It is recommended that a shut-off valve be installed upstream of the unit to enable maintenance. There must be safeguards in place to prevent the shut-off valve from being closed without authorization.

Note: Please refer to the Operation and Maintenance PDF below or CLICK this LINK for the illustration.

Mechanical Assembly

- Secure unit to floor using floor flange on base of unit.

- Connect water supply to the 1-1/4″ IPS union connection at the top or bottom of unit. If outdoors, make sure water supply pipe is protected from freezing.

- Test the device for leaks and verify that both the eyewash and shower function properly.

- Drain pipe under the eyewash valve allows water to drain after use to prevent the eyewash from freezing. Drain must remain unobstructed.

Note: Please refer to the Operation and Maintenance PDF below or CLICK this LINK for the illustration .

What others are saying

There are no contributions yet.